The car transporters are responsible for the collection and recycling of discarded vehicles in Norway. This responsibility is taken care of through the company Autoretur AS, of which the Bilimportørenes Landsforening is the owner.

Through a network of car collectors across the country, organized through three main operators, Norwegian scrap cars are collected. The wrecked cars then go through the high-tech recycling process that is needed to recover all materials from the wrecked cars. The materials are sold and reused for new products, and more and more car parts are reused. Thus, the materials from discarded cars become part of the circular economy.

Facts:

Norway got the first car scrapping scheme in 1978. The car importers took over responsibility for the return scheme in 2007 in line with the introduction of producer responsibility in the waste regulations. The responsibility is exercised through the car importer-owned company Autoretur AS, which is run on a non-profit basis.

The car haulers are responsible for the collection and recycling of scrapped vehicles. This responsibility is taken care of through the company Autoretur. The National Association of Car Porters owns the company.

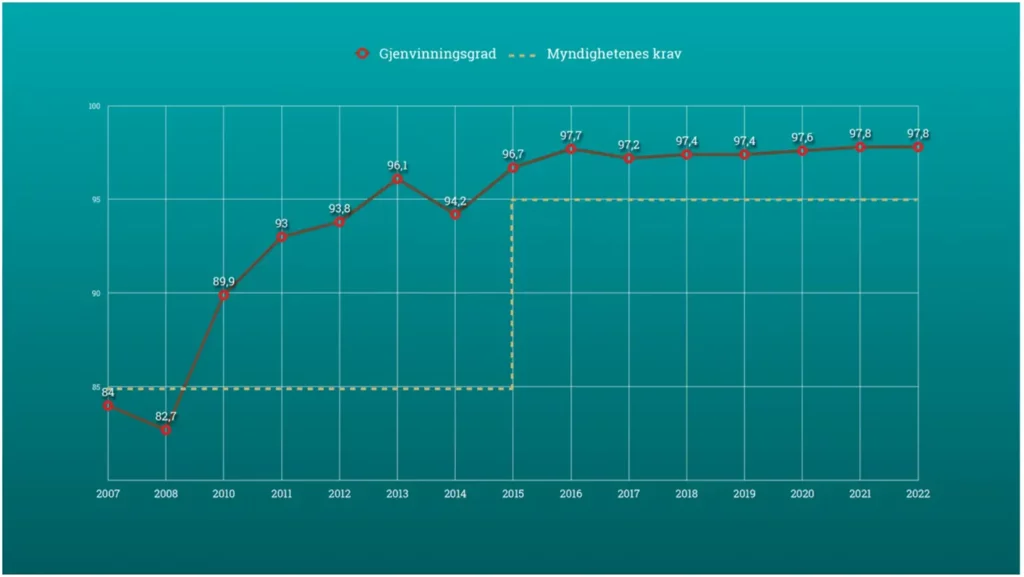

The EU requirements, which also apply in Norway, require car manufacturers to recover 95% of the wreckage through a publicly approved return system.

85% material recovery, 10% energy recovery, 5% can be landfilled

In practice, this means that almost the entire car must be able to be recycled or reused.

The car industry plays an important role for Norway to achieve the goals of a 55% reduction in emissions by 2030 through the transition to zero-emission technology. Even when the vehicles are to be scrapped, the car industry takes a significant environmental responsibility through Autoretur.

The car return scheme ensures proper recovery and recycling of scrapped vehicles. This is important to reduce CO2 and environmental emissions, and to increase the reuse of metals, which are a limited resource. A scrapping deposit of NOK 3,000 is paid for cars delivered for scrapping.

In 2022 it was scrapped113,338vehicles in Norway, and the materials in 131,800 tonnes of discarded vehicles were reused and recovered (material recovery).

Auto return achieved in 2022an overall recycling rate of 97.8% and 88.2% material recycling.

Reuse of parts from discarded cars is increasing sharply and the industry is changing. This is in line with EU directives on reuse.

On average, approximately 950 kg of metals from a wrecked car are reused. Heavy metals such as lead, cadmium and mercury are also removed.

Recycling and reuse of high-energy batteries, i.e. the propulsion batteries in electric and hybrid cars, are becoming increasingly important. Norway is currently pioneering in the field through the company Batteriretur – and Northvolt, which recycles high-energy battery cells at its new facility on Øra outside Fredrikstad. There they take out and reuse the active substances (lithium, cobalt etc.) from the high-energy batteries so that the rare metals can be used for new things.

Battery return material currently recovers around 70% of such batteries, and expects to reach 90-100% within a few years.

There is great potential for the reuse of high-energy batteries in several types of applications, including in connection with solar panels. Such applications can extend the lifetime of electric and hybrid car batteries.

In 2022, Autoretur developed a learning scheme for primary school students in collaboration with Skolerom.no. The learning program is available to a number of the country’s municipalities and schools.

The average lifespan of a car in Norway is 18.2 years. Older cars with high emissions and low safety levels should be replaced with new zero-emission vehicles. Norway will then be able to reach the Storting’s target of a 55% cut in emissions by 2030.

In Norway, the average life expectancy for passenger cars is just over 18 years. This means that there are a large number of older cars on the roads with high CO2 emissions and a low level of safety. Autoretur works to ensure that the authorities make arrangements for increased scrapping and thus a renewal of the car fleet with a higher proportion of zero-emission cars. This can be achieved, for example, with a higher scrap deposit.

The car industry is constantly criticized for not taking climate and environmental challenges seriously. For BIL, it is important to highlight that the industry takes a significant environmental responsibility through Autoretur, and that there are major climate and environmental benefits to be gained by exchanging old cars for new ones.