/

The automaker is teaming up with a small Minnesota-based startup to develop iron nitride-based magnets in the hopes of localizing a key aspect of its EV motor production.

Share this story

:format(webp)/cdn.vox-cdn.com/uploads/chorus_asset/file/25067147/GM_Niron_1.jpg)

General Motors is eyeing a new type of magnet for its EV motors that’s less dependent on rare earth minerals from China.

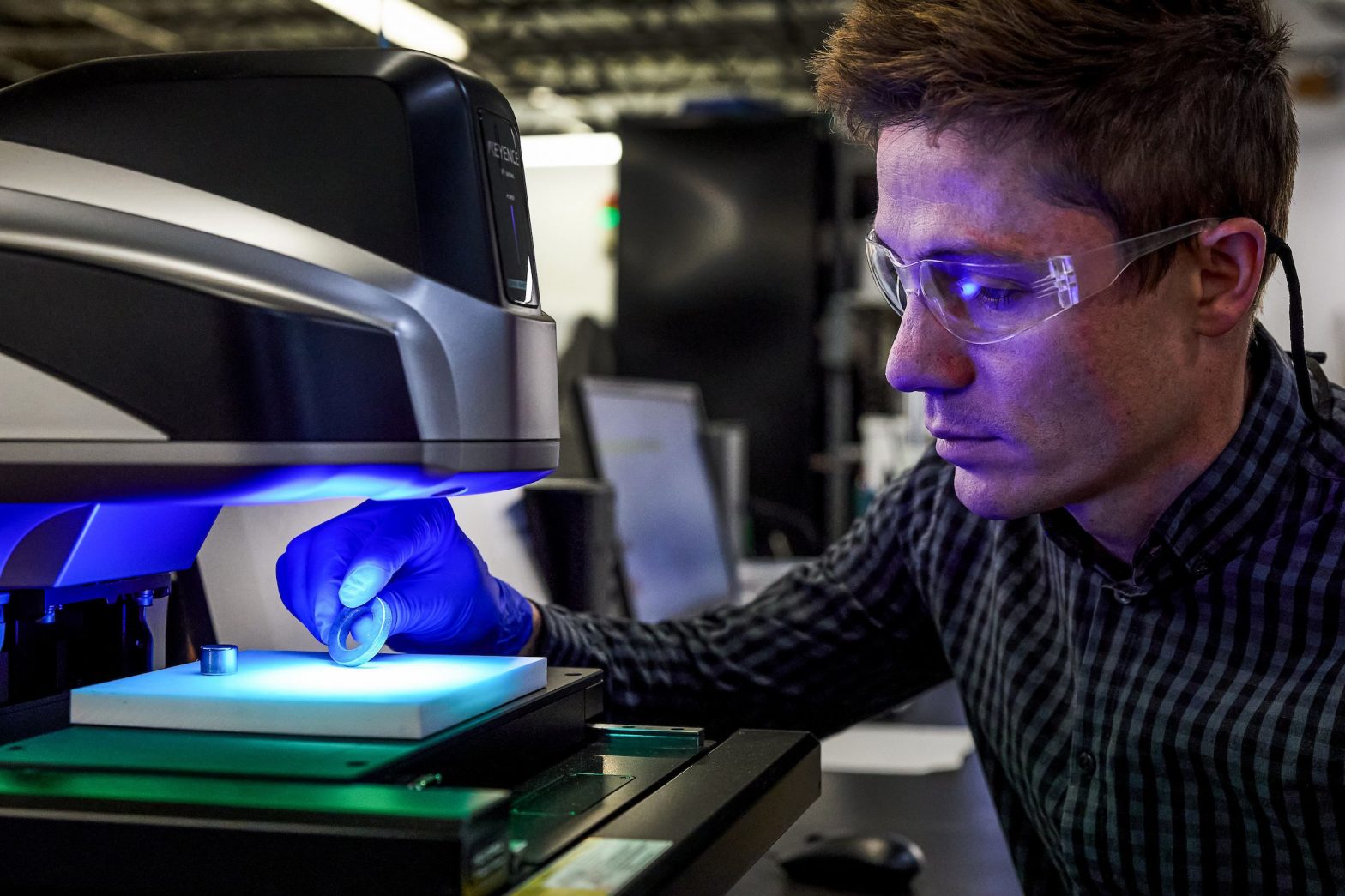

The automaker is forming a “strategic partnership” with Niron Magnetics, a Minnesota-based company that is developing magnetic technology based in iron nitride. GM’s venture arm is also investing an undisclosed sum into the company as it seeks to incorporate new technologies into its EV production.

The hope is that Niron’s magnets can eventually be used in the motors for the company’s electric vehicles, most of which currently use permanent magnets made from rare earth and heavy earth minerals from China. In contrast, Niron’s magnets purport to use iron nitride, which is comprised of the much-more-common elements of iron and nitrogen.

EV motors are powered by permanent magnets, sometimes no larger than a pack of playing cards, that are made of rare earth metals like like terbium, dysprosium, praseodymium, and neodymium. The magnets enable the motors to transform electricity to motion, which powers the vehicle’s acceleration.

But these metals are almost entirely mined and processed in China. And as tensions grow between that country and the US, the auto industry is under increasing pressure to find more local sources for these materials.

Another wrinkle is the rules governing the electric vehicle tax credit, which requires automakers to source battery and motor components from the US and its trade partners in order to qualify for the $7,500 discount. By teaming up with Niron, GM is making a long-term bet that the magnets can eventually help supplement the need for Chinese parts that may run afoul of the tax credit rules.

:format(webp)/cdn.vox-cdn.com/uploads/chorus_asset/file/25067171/GM_Niron_2.jpg)

“There’s a great fit here,” said Niron CEO Jonathan Roundtree, in a call with reporters this week, “with Niron’s technology and GM’s aspiration to make EVs more sustainable and more affordable.”

The company has previously raised over $100 million from outside investors, including $17.5 million from the US Department of Energy’s Advanced Research Projects Agency. Niron, which is based in Northeast Minnesotta, intends to use the funds from GM Ventures to double its size from a current workforce of 60 employees.

The technology is still under development, and Niron hopes to use GM’s investment to scale up production of its magnets to match the auto industry’s enormous needs for EV motor components. The automaker has said it intends to no longer sell gas-powered vehicles by 2040 — even as it reins in some of its ambitious plans in the face of rising interest rates and softening demand for EVs.

The deal isn’t exclusive; Niron said it intends to sell its magnets to other automotive partners, as well as other companies in the business of sustainable energy.

And GM has no plans to curtail its use of permanent magnets made from rare earth minerals. The company recently inked a deal with Nevada-based MP Materials to source rare earth materials, alloy, and finished magnets for its EV motors.