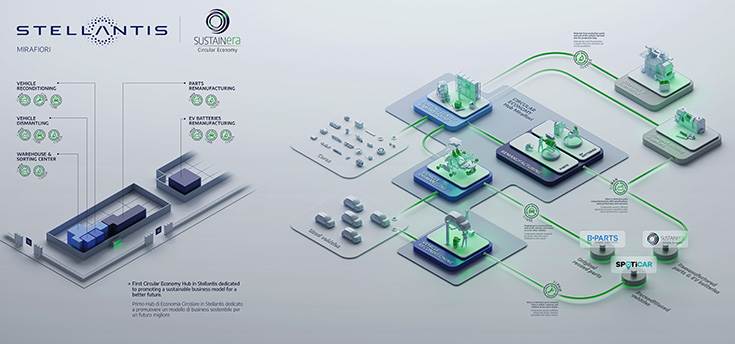

Stellantis has had the official opening of its SUSTAINera Circular Economy Hub (CE Hub) at the Mirafiori Complex in Turin, Italy. The 14-brand company has a comprehensive plan to foster its Circular Economy ambitions with a 360-degree approach based on the 4R strategy: Reman, Repair, Reuse, and Recycle.

The primary objectives of the state-of-the-art Circular Economy Hub are to extend the life of parts and vehicles, ensuring that they last for as long as possible. When that is no longer possible, the material is collected for recycling from the remanufacturing activity, and from the end-of-life vehicle dismantling activity, and then returned to the manufacturing loop to build new vehicles and parts. The CE Hub initially hosts four activities implementing the 4R strategy, with the scope set to expand further:

Remanufacturing (Reman): used, worn, or defective components, such as engines, gearboxes and EV batteries are disassembled, cleaned, and remanufactured to original OEM specifications, without compromising quality. The goal is to offer a sustainable and affordable alternative available under the SUSTAINera label within the Stellantis spare parts offer. The facility expects to manage over 50,000 remanufactured parts by 2025, rising to 150,000 by 2030.

Sorting Center (Reman, Recycle): an estimated 2.5 million worn parts, known as cores, will supply the facility’s remanufacturing and recycling activities by 2025, increasing to 8 million by 2030.

Vehicle Reconditioning (Repair, Reman, and Reuse): vehicles will be repaired aesthetically and mechanically using new, remanufactured or used parts and then reintroduced through SPOTiCAR, Stellantis’ manufacturer-certified used-vehicle program, and the Stellantis &You, Sales and Services network.

Vehicle Dismantling (Recycle, Reman, and Reuse): at the end of their life cycle, vehicles become a precious resource for parts to be remanufactured, reused or as material for recycling. Specifically, the used OEM parts managed by the CE Hub will integrate the stock available from our partner B-Parts to source the SUSTAINera Reuse offer.

Generating efficiencies and benefiting from synergies

The high-performance CE Hub will generate efficiencies and synergies among the activities and vertical integration of materials and processes.

Stellantis is building its capabilities, teams, and facilities to change its consumption model, creating a smart, integrated ecosystem to reduce the environmental impact and better manage the company’s aggressive decarbonisation target of reaching carbon net zero by 2038.

“The Circular Economy Hub brings together a powerhouse of skills and activities aimed at creating a high-performing center of excellence in Europe,” said Stellantis CEO Carlos Tavares. “We are industrializing the recovery and sustainable reuse of materials, building new technologies and advanced capabilities as we grow in this area. We know that our commitment to remanufacturing, repairing, reusing and recycling will not only take pressure off our planet, but it will also bring financial value to Stellantis, safeguarding our shared future as we quickly transform our production and consumption business model.”

Stellantis took a circular economy mindset in bringing the site to life enabled by an investment of 40 million euros. The CE Hub occupies a total area of 73,000 square metres, of which 55,000 square metres have been recovered from a partially unused facility. Stellantis also recycled more than 5,000 tons of metal of obsolete assets in the process. Equipment and machinery for the facility was repurposed from other locations bringing a 55% saving compared to purchasing new machinery and equipment. The site currently employs 170 upskilled employees. This number is projected to increase to approximately 550 people by 2025.

In addition to supporting its primary activities, the Circular Economy Hub also complements Stellantis’ recent actions to strengthen its global electrification ecosystem and support its carbon neutrality ambitions, including:

– Partnering with Orano for the pre-treatment within the EV batteries recycling process to reclaim cobalt, nickel, and lithium from end-of-life vehicles and scrap from gigafactories;

– Forming the SUSTAINera Valorauto SAS joint venture with Galloo to manage end-of-life vehicles;

– Teaming up with Qinomic to develop electric retrofitting of light commercial vehicles. The prototype is being presented (through November 25) at the Solutrans trade show at the Lyon Euroexpo in France;

– Establishing strategic partnerships for raw EV battery materials and six planned gigafactories across Europe and North America; and,

– Opening its first Battery Technology Center in the Mirafiori Complex for in-house testing and development of EV batteries.

The Stellantis Circular Economy Business Unit is one of the seven accretive business units announced in the Dare Forward 2030 strategic plan, and it targets to generate more than 2 billion euros in revenues by 2030.