/

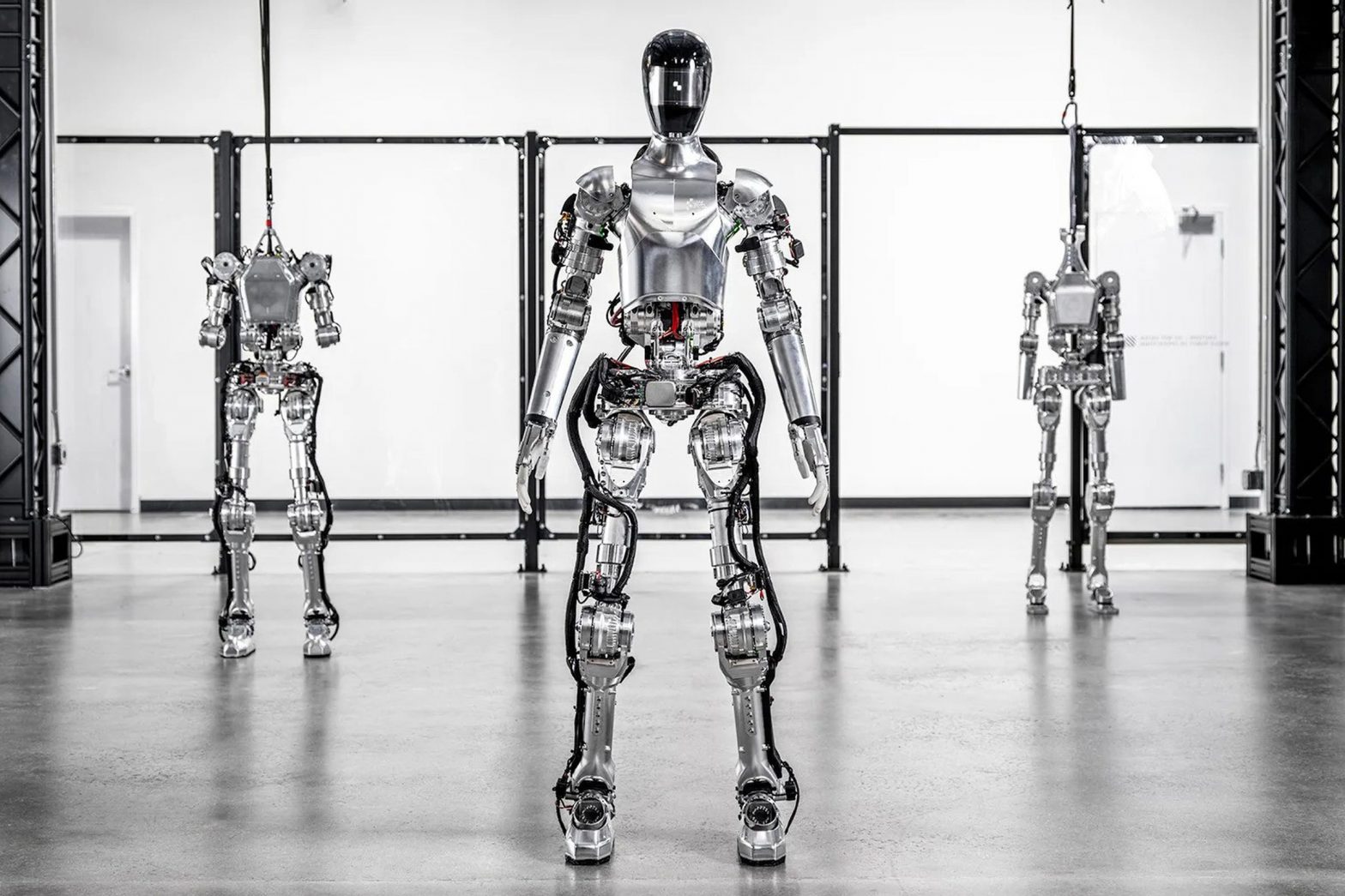

The ‘general purpose’ robots from robotics startup Figure are intended to automate dangerous or repetitive manufacturing tasks.

Share this story

:format(webp)/cdn.vox-cdn.com/uploads/chorus_asset/file/25234298/Figure_robotics_prototype.jpg)

Robotics startup Figure has signed a “commercial agreement” with BMW to introduce its “general purpose” humanoid robots to BMW’s manufacturing facility in Spartanburg, South Carolina, as it tries to identify use cases in automotive production. The robots are intended to automate “difficult, unsafe, or tedious” manufacturing tasks, and if they’re found to be viable, they’ll then be deployed in the BMW facility in stages.

“Single-purpose robotics have saturated the commercial market for decades, but the potential of general purpose robotics is completely untapped,” said Figure CEO Brett Adcock. “Figure’s robots will enable companies to increase productivity, reduce costs, and create a safer and more consistent environment.”

Car manufacturers like Honda and Hyundai have had a visible presence in the development of walking robots over the years, but attempts at integrating them into the real world are ramping up. Tesla unveiled the second generation of its Optimus robot back in December, and Amazon is trialing Agility Robotics’ “Digit” robot in its US warehouses.

The BMW manufacturing facility in South Carolina is the company’s only US-based plant, where it assembles around 1,500 X-series and XM-series vehicles every day. It currently employs around 11,000 people and is the largest automotive exporter in the US by value, with an export value of $9.6 billion.

Neither company has disclosed how many of Figure’s humanoid robots will be deployed at the facility or what tasks they’re expected to undertake, though Adcock told Reuters that the partnership will start with “small quantities” that will increase if performance targets are met. The Reuters report also gives a fairly wide window for deployment to allow Figure to train the bots to perform specific tasks — it could take anywhere from 12–24 months for them to actually be integrated into BMW’s manufacturing processes if it does identify a viable use for them.