Since 1917, AIDA has led the metal-forming industry as the well-known manufacturer of metal-forming systems, particularly servo and mechanical presses for various applications in the global automotive and component industries, including OEMs and Tier 1 to Tier 3 suppliers. Since the founding of AIDA Greater Asia in 1989, the regional network now has seven sales and service support centres located in Singapore, Malaysia, Thailand, India, Vietnam, Philippines and a manufacturing base located in Johor, Malaysia.

AIDA has been operating a comprehensive sales and service network in India since 2007. Over the last 17 years, the company has offered tailored metal forming solutions and maintenance services support to both local and international clients in India. Additionally, AIDA established a press showroom in Chennai, Tamil Nadu, ensuring the “Immediate delivery” of press equipment and range of ready stock spare parts and accessories.

The company offers presses for forming automotive body panels, precision presses for motor cores lamination in electric vehicles, and peripheral equipment for automation. The company’s business emphasis is on providing fully integrated production lines to enhance productivity for OEMs.

This aspect is now deemed as an important consideration, as OEMs look forward to enhancing their respective scales of efficiency and optimisation of processes.

AIDA specialises in metal forming equipment for the industry. Can you share the business you do with the automotive sector in India and in the Asia region, especially for EVs?

Yes, AIDA specialises in providing a comprehensive range of presses to support the global automotive industry. Our clients include OEMs, Tier 1 to Tier 3, component production units in 2 wheelers and 4 wheelers Electric Vehicles (EVs).

We take pride in offering large servo presses for forming automotive body panels and high-speed precision presses, specifically designed for motor core lamination in electric vehicles. Apart from presses, we also develop and manufacture peripheral equipment essential for automation. This includes material feeders, transfer robots, product removal equipment, and other components crucial to the automation of our press lines. The unique aspect of our offering is the ability to provide a fully integrated production line, elevating productivity for our clients.

Moreover, AIDA’s proprietary DSF Direct servo former technology is widely used to form high-strength steel sheets and other difficult-to-form Materials. Reducing the weight of vehicle bodies is a major priority in the quest to lower CO2 emissions. However, collision safety cannot be overlooked either. As the transition to electric vehicles continues, there is a need to protect batteries as well as drivers. High-strength steel sheets offer high resistance to external impacts and are being increasingly used because they are rigid as well as lightweight.

AIDA’s advanced servo forming methodologies and forming systems help in managing hard and difficult to form high-strength steel sheets into even more highly contoured shapes at faster production speeds. AIDA has independently developed servo motors that deliver the immense power required by servo presses, and they enable high productivity and high-accuracy production that is also energy efficient.

For press shop machines, there’s a high level of wear and tear that requires to be addressed to help increase the working lifespan of the machines.

You are right. The lifespan of press is very important for us. We offer a range of after sales services that include both preventive and corrective maintenance, to ensure the durability of our press equipment and to support trouble-free use for many years after delivery. AIDA’s commitment is not just to deliver a product but to sustain and strengthen our relationships with customers over the long term.

We offer after sales services including repairs, troubleshooting, retrofits, upgrades, overhauls, preventive maintenance, press inspections and machine relocations among others.

Tell us about the digital transformation technologies that AIDA is applying to the machines.

The utilisation of DX technologies such as visually monitoring operation conditions and production, and using AI to identify signs of potential issues, serve to reduce the burden on personnel and make it possible to maintain stable operations that will not be affected by the experience levels of individual workers. Our latest Servo press DSF-N2-4000A series is equipped with a load monitoring system that leverages AI to lengthen the die life. During the press forming process, dies are used to apply the load to form materials. Failure to appropriately apply these loads could result in defective products or damaged dies.

The customary load monitoring method is to use a 2D graph to display 4 load points on the bolster, but the AIDA monitoring system enables users to see the load shifts over the entire bolster in a 3D graph immediately. AI monitors whether load waveforms are distorted and whether the maximum load is occurring at the appropriate point, which makes it possible to extend the life of dies.

How is AI helping to add value to your business?

Digital transformation is leading to the development of new business models and the creation of new value, thereby driving significant changes in manufacturing industries. AIDA continues to make inroads into not only “preventive maintenance” that uses IoT technology to monitor the service life of parts, but also “predictive maintenance,” that uses AI technology to learn and to detect early warning signs of impending issues. Our press machines aggregate measurement data, for example, the temperature of each part and the servo motor current and voltage values, and learn from it, enabling automatic diagnosis of the machine status and the quantification of abnormal conditions to help prevent problems before they occur.

AIDA’s advanced servo forming methodologies and forming systems help in managing hard and difficult to form high-strength steel sheets into even more highly contoured shapes at faster production speeds.

AIDA’s advanced servo forming methodologies and forming systems help in managing hard and difficult to form high-strength steel sheets into even more highly contoured shapes at faster production speeds.

How important is preventive maintenance for your client’s processes?

Preventive Maintenance helps to make sure the press equipment is working in tip-top condition. Through preventive maintenance, signs of breakdown can be detected. Early adjustment and maintenance work are to be done beforehand, to prevent sudden halt of presses and reduce effects on the production line to the minimum. In addition, regular inspecting and replacing press components ensure presses to run with great and steady performance for a long time. Apart from keeping presses working efficiently, preventive maintenance has other strong points, such as:

- Reducing downtime

- Improving quality production

- Increasing press machine efficiency

- Lower cost for maintenance and materials

- Gain a competitive advantage over competitors

We help optimise the preventive maintenance process through “Component Service Life Management programmes” in AiCARE, AIDA’s IoT information management system. For example, there are special sensors mounted on the machinery that can collect data in real time and provide the information needed by operators, maintenance managers, production managers, and others involved in production, in an optimised format. Using actual operating status data, press operators will be notified when components have reached the “wear-out failure period.”

Apart from steel components, aluminium is also used in stamped products by the automotive industry. What solutions do you offer for aluminium?

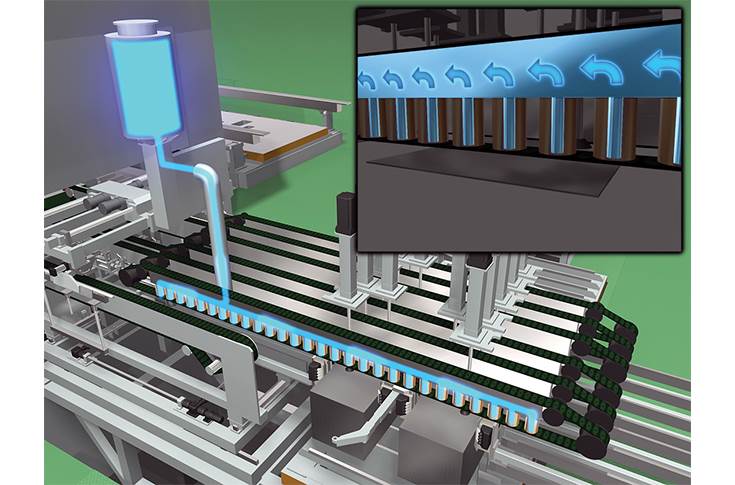

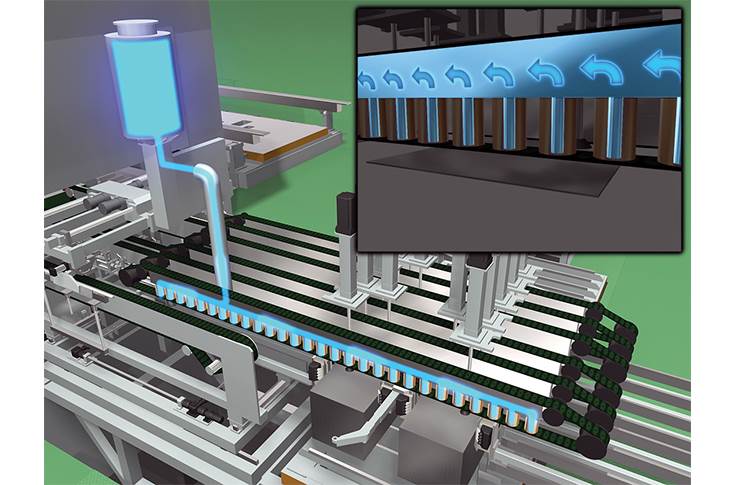

We understand that efforts to reduce vehicle weight have led to a rising demand for aluminium components. AIDA’s DSF Servo presses are the ultimate solution to shape difficult-to-form materials, such as high-strength steel sheets and aluminium. We independently developed the optimal low-speed, high-torque servo motors that deliver the immense power required by servo presses, and they enable high productivity and high-accuracy production that is also energy efficient. Because aluminium is not magnetic, it cannot be formed using a conventional press line where magnets are used to convey steel materials from point A to point B. Our engineers have designed a highly practical destacker system that uses magnets for conveying steel materials. A different approach is used for conveying aluminium materials where we have designed a vacuum pressurised machine to do the job. This way, both aluminium and steel materials can be transported from one end to another in the press line efficiently.