Elon Musk might give up on Tesla’s 4680 battery cell if the situation doesn’t improve by the end of the year.

Tesla’s 4680 battery cell, the automaker’s first effort to build its own cells, hasn’t gone smoothly, to say the least.

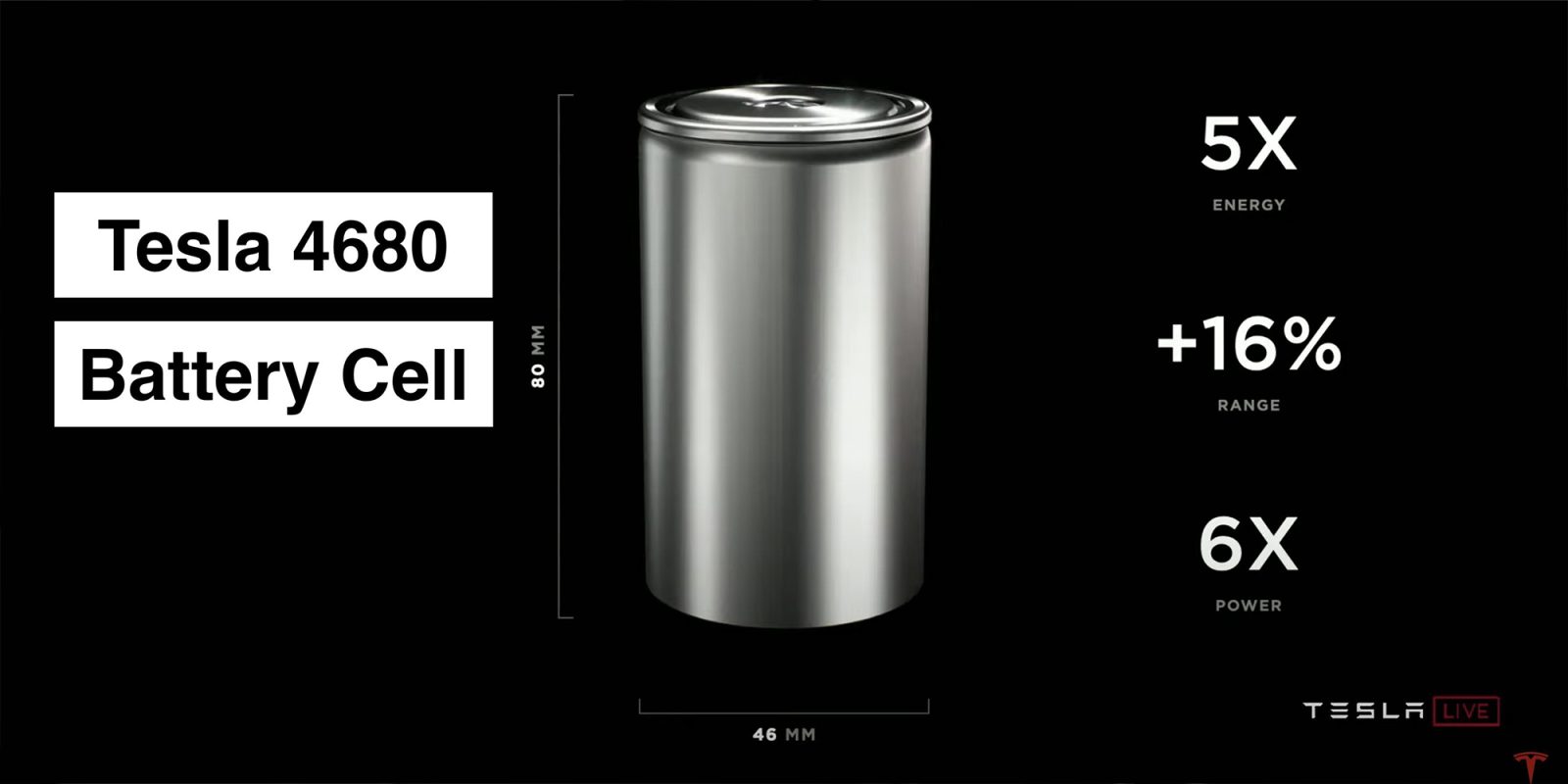

First announced in 2020, it promised to enable significantly lower cost, more range, and faster charging. Ultimately, it would enable Tesla to achieve a higher volume of electric vehicle production at lower costs.

However, those results haven’t materialized yet.

Tesla has managed to ramp up 4680 cell production at the gigawatt-hour scale, but production is still at a fraction of the volume where Tesla planned to be by now and the cell is currently only being used in the $100,000 Cybertruck. Though it was used for a time in some Model Y produced at Gigafactory Texas.

The limited use of the 4680 cells produced by Tesla is believed to have to do with the cell not being at the level Tesla planned, both on the performance side and on the cost side.

Now, The Information reports that Musk has given Tesla’s 4680 team a deadline for the end of the year to fix the cell:

In May, Musk told the team working on the 4680—the nickname for the cylindrical battery, which is 46 millimeters in diameter and 80 millimeters tall—to cut its cost and scale up one of its key innovations by the end of the year, according to three people with knowledge of the matter. And in recent months, Musk has told them he wants to see a solution to a thorny technical problem that can cause the batteries to collapse on themselves while in use, one of those people said.

Two people interviewed by The Information said that Musk might give up on scaling the cell if the issue is not fixed by the end of the year.

One of the main hurdles seems to be the dry coating of the cathode. Dry coating is a technology Tesla acquired through its acquisition of Maxwell Technology, and it has been expected to be one of the biggest contributors to the expected performance and cost improvement of the 4680 cell.

It eliminates the costly wet process, which Tesla successfully implemented on the anode, but not on the more costly cathode.

The report states that Tesla aims to fix that by the end of the year to achieve this goal. Otherwise, it’s possible Tesla will give up on the plan.

Tesla has recently stated that it expects to beat the cost per kWh of cell suppliers with its own 4680 cell by the end of the year.

Electrek’s Take

It seems like a big investment to give up on. Tesla has built a large part of Gigafactory Texas around cell production.

But if it’s not working after 4 years, you have to make the call at some point.

I’d like to see Tesla stay in the battery cell business even if it’s at a lower scale in case we have another battery shortage.

For now, it seems like battery suppliers have caught up to automotive demand as many have slowed down their electric transition, but I expect this could change fast again in the next two years.

FTC: We use income earning auto affiliate links. More.