The Hyundai Motor Group’s electric passenger vehicles, which have been built on the Electric-Global Modular Platform (-GMP) models, are benefiting from receiving the highest level of report cards in the world’s major crash safety assessments.

The Group’s five dedicated EV models – Genesis GV60, Hyundai Ioniq 5 and Ioniq 6, Kia EV6 and Kia EV9 – all received the highest rating of five stars in the Euro NCAP (New Car Assessment Programme), the new vehicle safety evaluation program in Europe. And all models received TSP or higher ratings in the crash evaluation released by the Insurance Institute for Highway Safety (IIHS) in United States. The Kia EV3 has not been evaluated as it has been released this year.

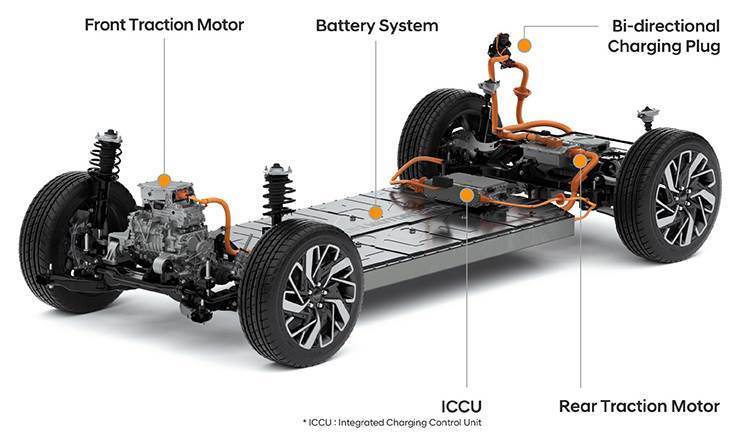

The Group’s E-GMP, known for its versatility through modularity and standardization, prioritizes safety and innovative design, while also supporting multi (400/800V) rapid charging system and Vehicle-to-Load (V2L) functionality, providing what the automaker states is “an exceptional electric driving experience”.

The Korean group’s first bespoke EV architecture is designed to underpin cars of varying sizes from Hyundai, Kia and Genesis, ranging from hatchbacks to full-size SUVs, as part of its strategy to introduce 23 full EVs by 2025 and sell more than 1 million BEVs worldwide by 2025.

The Group has maintained its World Car winning streak for three consecutive years, beginning with the Ioniq 5 in 2022, followed by the Ioniq 6 in 2023, and the Kia EV9 in 2024. All three EVs are all based on the Group’s Electric-Global Modular Platform (E-GMP), introduced in December 2020.

E-GMP, known for its versatility through modularity and standardization, prioritizes safety and innovative design, while also supporting multi- (400/800V) rapid charging system and Vehicle-to-Load (V2L) functionality

E-GMP, known for its versatility through modularity and standardization, prioritizes safety and innovative design, while also supporting multi- (400/800V) rapid charging system and Vehicle-to-Load (V2L) functionality

Specially designed for new-gen EVs

E-GMP has a special design and structure that differentiates it from the existing internal combustion engine platform according to the characteristics of EVs that are equipped with batteries.

The design that uses the battery pack as a structure increases the rigidity of the car body, and at the same time, aluminium extrusion material is applied to the inside of the side sill located outside the battery from the side of the body to distribute the impact to the lower frame and battery case in the event of a side collision to ensure safety.

In addition, an eight-point fastening structure between the car body and the battery is applied to achieve a solid bond, and in the event of a rear-end collision, the rear member is deliberately deformed to absorb shock, while the lower member is reinforced with a hot-stamped steel plate to prevent deformation of the safety zone to prevent battery damage.

The load path was optimized to effectively distribute the impact energy generated in a frontal collision by applying a multi-skeletal structure, and the multi-skeletal structure was completed with a double-box member design in consideration of situations where the impact energy is concentrated in a part of the front, such as a small overlap.

As a testament to the top-notch safety design of E-GMP, Hyundai Motor Group’s dedicated EV models have achieved the highest level of safety in new vehicle safety evaluations in major countries.

According to the automaker, in this year’s IIHS crash evaluation, Hyundai Motor Group has secured excellent crash safety performance across all models, including dedicated EVs and internal combustion engines, with a total of 20 models rated TSP or higher, which is the largest number of models among global automakers as of today (Toyota Group 14 models, Hyundai Motor Group manufacturers: Hyundai Motor Company 9, Genesis 7, Kia 4).

ALSO READ: Hyundai Motor Group increases annual EV sales target by 2030 to 2 million units

Hyundai and Kia partner Exide Energy to produce LFP batteries in India

Hyundai and Kia’s ‘Active Air Skirt’ technology to make EVs go faster and farther