Ford Motor Company has leveraged SLA and SLS 3D printers from Formlabs to prototype several components for its new Electric Explorer SUV.

The world’s sixth-largest automotive manufacturer, Ford beta-tested Formlabs’ newest 3D printer, the Form 4, to streamline its car design process. This added to its existing Formlabs Form 3L and Fuse 1+ 30W systems.

The company used 3D printing to prototype designs for key components of its new electric SUV, including mirrors, handles, charging ports and dashboard parts. This has reportedly allowed the workshop team to take more risks, unlock complex designs, and quickly prototype new design iterations in hours rather than days.

By streamlining its design process with additive manufacturing, Ford hopes to deliver on its commitment to offering an entirely electric vehicle (EV) lineup in Europe by 2030. The speed of 3D printing is reportedly essential to meeting this tight timeframe.

“If we didn’t have access to additive manufacturing, we would not be able to compete with the competitors, we would not be able to be so fast,” explained Bruno Alves, Additive Manufacturing Expert and Tooling Specialist at Ford.

“Additive manufacturing is very important in the development process. It gives you the opportunity to produce parts very quickly, very efficiently, and reduce costs,” added Sandro Piroddi, Supervisor of the Rapid Technology Center at Ford.

Ford leverages Formlabs’ new Form 4

Ford’s PD Merkenich Rapid Technology Center is the automotive manufacturer’s development facility, responsible for designing all passenger vehicles for the European market. Here, SLS, SLA, FDM and metal 3D printers have long played a role in producing vehicle prototypes.

Notably, resin 3D printers from Formlabs are playing a key role in designing Ford’s latest range of EVs, including the Electric Explorer SUV. SLA 3D printers are mainly used in workshops to design prototypes that require a high-quality surface finish. These parts also need to be produced quickly to enable quick iterations.

Ford became one of the first companies to adopt the Form 4, Formlabs’ newest MSLA 3D printer.

Launched earlier this year, the Form 4 offers high-speed 3D printing, reliability, and quality material properties. Its accelerated print speeds are a significant differentiator from its predecessor, the Form 3+. The new resin 3D printer can complete standard print jobs in under two hours and boasts vertical speeds of up to 100 mm/hr.

“The Form 4 is very fast, I think it is the best machine that I’ve seen until now in terms of speed. It’s really a very good upgrade compared to the previous models,” commented Alves. “It’s easier to operate, so it’s much easier for the operators in our workshop to learn how to work with the machine and get parts with good quality.”

Piroddi called the Form 4 a “game changer” thanks to its fast 3D printing speeds, allowing Ford’s development team to increase throughput and achieve more design flexibility. The team can now fulfil more requests in under 24 hours and deliver overnight shipments of parts to the UK.

SLA 3D printing has played a key role in validating the design of many exterior and interior parts for the new Ford Electric Explorer. Formlabs’ Form 3L, a large-format SLA 3D printer, was used to 3D print big exterior parts in one piece. This included the rear-view mirror cap, the charging port cover, and dashboard features.

SLS 3D printing streamlines electric vehicle prototyping

Ford also operates a large suite of SLS 3D printers to test mechanical car parts, including Formlabs’ Fuse 1+ 30W, which can 3D print PA-12 nylon material. This possesses properties that are very similar to the injection molded mass production parts.

The company was also one of the first to beta-test Formlabs’ Fuse Blast automated cleaning and polishing system. This is said to have accelerated Ford’s prototyping process by removing the need for manual post-processing.

A key advantage of SLS technology is that it does not require support structures, allowing it to 3D print more complex designs. As such, the Fuse 1+ 30W was used to produce various mechanical parts and assemblies for the new Explorer. This included the electric SUV’s complex charging port, which reportedly could not have been prototyped with any other manufacturing method.

“It’s a really complex design that we are not able to produce in any other way. We cannot mill this part. We cannot use injection molding to produce just some samples,” stated Alves. “So the best way is to print in a material that we can test physically.”

3D printing unlocks in-house injection molding

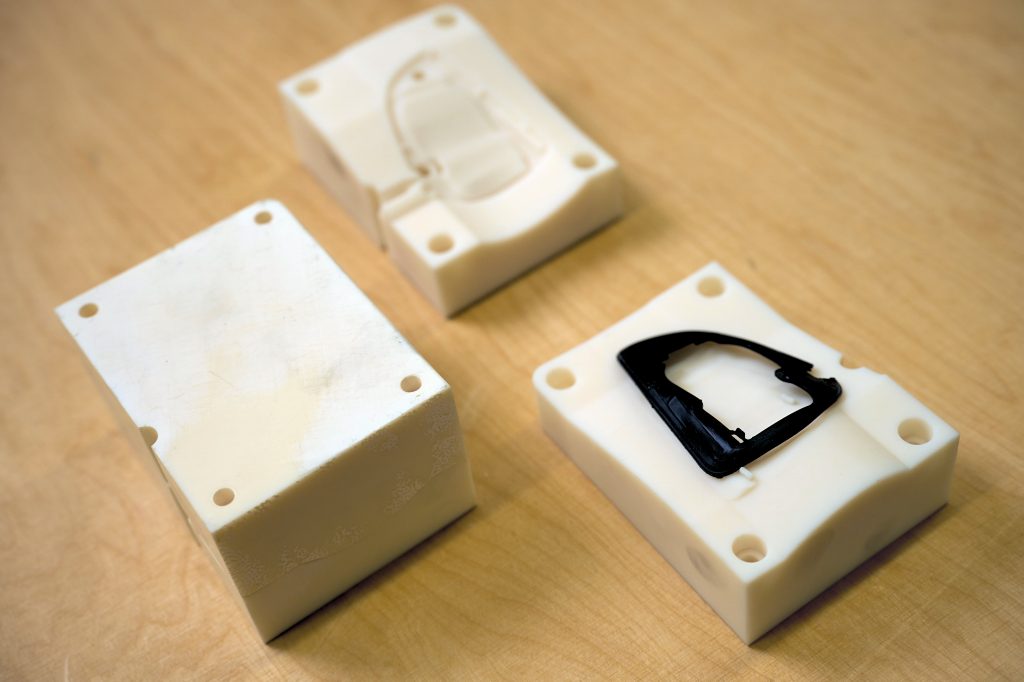

Ford has also combined traditional manufacturing processes with 3D printed rapid tooling. This allows the team to determine and select the most suitable production process and material for different applications, cutting costs and increasing workflow efficiency.

In vehicle crash tests, components must be constructed from the same material and process as the mass-produced final part. Plastic parts are typically produced through injection molding, which usually requires costly and time-consuming metal tooling.

“We see a lot of potential using 3D printing inserts for injection molding based on the fact that we can iterate the design very fast. We print cavities in cores and then we can change them in the tool and inject the parts,” added Alves.

For the new Explorer, Ford produced rubber components for the SUV’s door handle assembly in-house using 3D printed mold inserts. External injection molding typically takes two to three months. However, by additively manufacturing the inserts in-house, Ford can complete this process in under three weeks. The team 3D printed the mold inserts in Rigid 10K resin on their SLA 3D printers, and Nylon 12 Powder on SLS.

“For this project, if we had to use external tools, it would have been much more time-consuming and we would not have been able to deliver the parts on time,” explained Alves.

Additive manufacturing for automotive applications

Ford isn’t the only automotive manufacturer integrating additive manufacturing into its design and production workflow.

Last year, Global industrial 3D printer manufacturer INTAMSYS partnered with printing materials supplier KEXCELLED to provide FDM 3D printing capabilities to the Automotive Division of SIKA in China.

By 3D printing car parts, SIKA has seen time and cost savings of up to 90% for its automotive prototyping and development stages. INTAMSYS’ 3D printing technology has also been leveraged to produce interior and exterior car accessories, including customized bumpers, steering wheel test pieces, racing car parts, and tail logo fixtures.

Elsewhere Japanese automotive multinational Toyota has previously adopted the Zortrax M300 Plus to 3D print assembly jigs and fixtures. Adopting the FDM 3D printer has reportedly optimized its vehicle assembly operations, reducing costs and lead times behind manufacturing essential tools and spares.

Toyota’s dedicated 3D printing labs, based in their Polish facility, have installed more than 100,000 zł ($23,000) worth of Zortrax equipment. The parts currently 3D printed at the plant fall into four categories: positioning jigs, assembly jigs, assembly tools, and covers. These parts are often combined with other components produced using subtractive processes to form integrated assemblies.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows the new Ford Electric Explorer. Photo via Ford Motor Company.