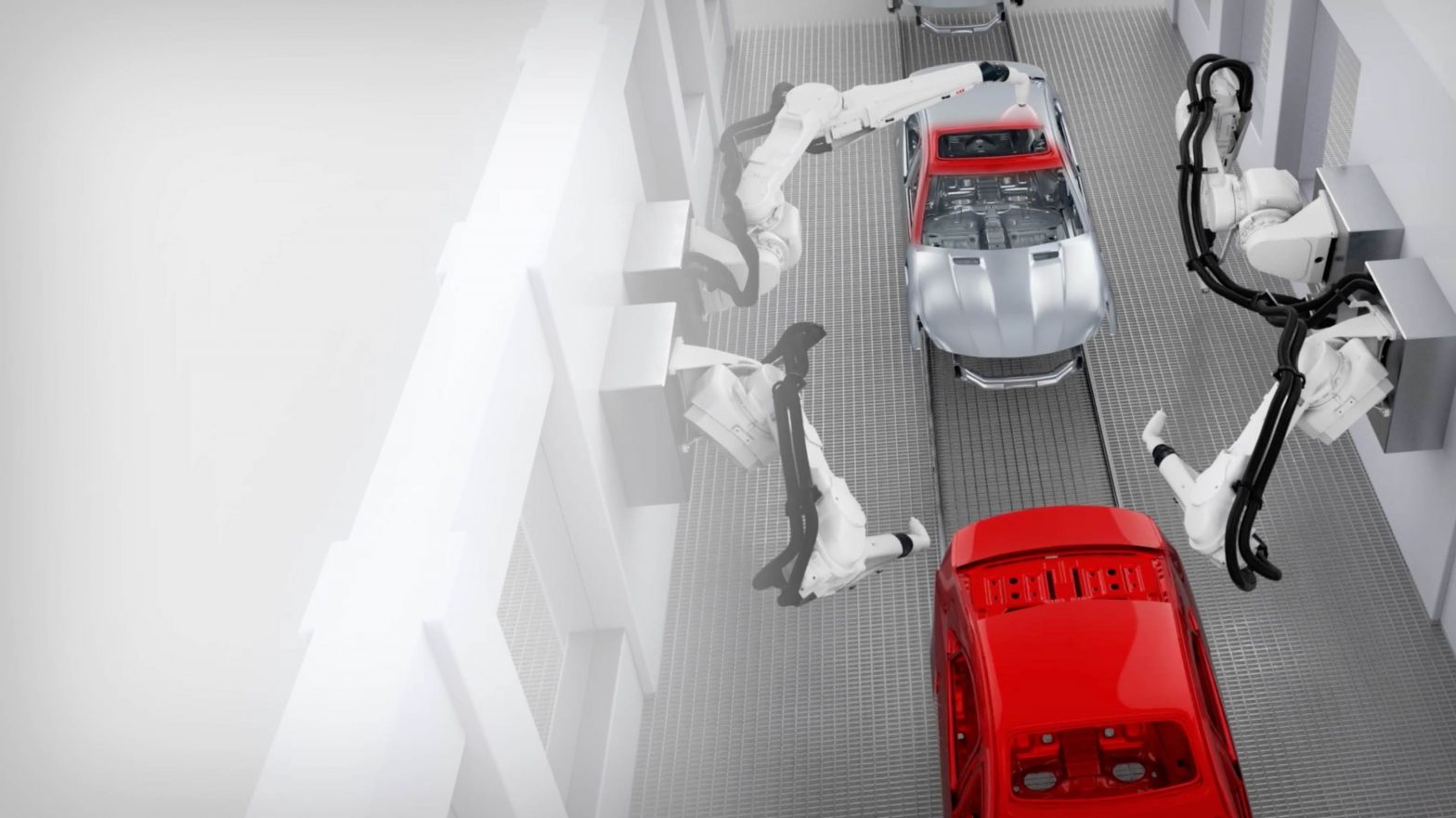

ABB has launched the RB 1000i-S paint atomizer to revolutionize automotive paint shops. The new paint atomizer mounted on top of the ABB robot improves transfer efficiency by upwards of 10%, and can significantly reduce paint waste by a minimum of 30% along with carbon dioxide (CO2) emissions, compared to its predecessor, the RB 1000i. In addition, major efficiency and cost saving benefits have the potential to deliver significant financial savings.

“Major automotive manufacturers have committed to carbon neutral factories by 2035, leaving no stone unturned in their mission to achieve these targets,” said Marc Segura, President – Robotics Division at ABB. “ABB is continuously developing products and services to help companies achieve their sustainability targets. The newly launched RB 1000i-S is just one example of how ABB is expanding its portfolio to help meet the challenges that lie ahead.”

The RB 1000i-S paint atomizer reduces CO2 and Volatile Organic Compounds (VOC) emissions in automotive paint shops by reducing paint waste, as well as the overall energy consumption in plants through a more efficient paint process.

Cost savings can also be significant. For example, where a manufacturer utilizes a 2.5-litre paint solvent borne per car and produces 200,000 cars per factory annually, the RB 1000i-S paint atomizer through its improved transfer efficiency can help to save 50,000 litres of paint per factory. This equates to US$ 500,000 (Rs 4.16 crore) in direct financial savings.

According to ABB, customers can order the new RB 1000i-S atomizer with a new paint robot, or they can purchase a service kit to upgrade their existing RB 1000i by replacing key components, such as the bell cup and shaping air nozzle. The service upgrade kit supports the circular economy and maximizes the lifespan of the existing paint atomizer, increasing product durability and further reducing waste.