Mahindra & Mahindra, which is to open bookings for all nine variants of its new electric-origin BE 6 and XEV 9e SUVs on February 14, has produced 2,281 units of the two zero-emission models at its EV-specific facility in Chakan, Pune and dispatched 1,837 units to its authorised dealers. This data is as per the company’s official production and sales numbers for January 2025 released earlier this month. It needs to be noted that both production and dispatch numbers would have increased in the past 12 days of February 2025. The new BEV model-wise, however, is not known.

The company is bullish on customer demand coming its way for these two premium zero-emission SUVs, which push the EV envelope with their high-performance drivetrains, in-house assembled lithium-ion phosphate battery packs, top-notch crash safety standards, and a host of interior features benchmarked to the highest level.

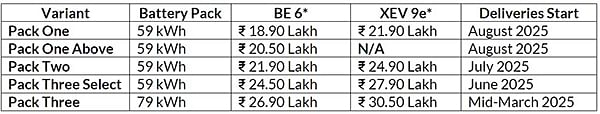

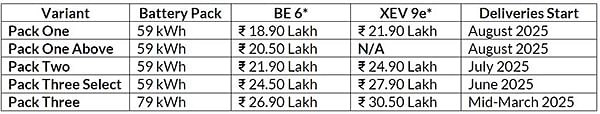

Deliveries of the two new BEVs equipped with the 79 kWh battery pack, which has a certified range of 682km (BE 6) and 656km (XEV 9e), will commence in mid-March 2025.

Deliveries of the two new BEVs equipped with the 79 kWh battery pack, which has a certified range of 682km (BE 6) and 656km (XEV 9e), will commence in mid-March 2025.

The BE 6 and XEV 9e are built on the INGLO modular, lightweight skateboard architecture platform which delivers a host of benefits across multiple fronts.

The BE 6 and XEV 9e are built on the INGLO modular, lightweight skateboard architecture platform which delivers a host of benefits across multiple fronts.

Built on the INGLO platform

The BE 6 and XEV 9e are both built on the INGLO modular, lightweight skateboard architecture platform, which is the foundation of Mahindra’s Electric Origin SUVs and represents a fusion of Indian innovation and global standards. This delivers a host of benefits across multiple fronts.

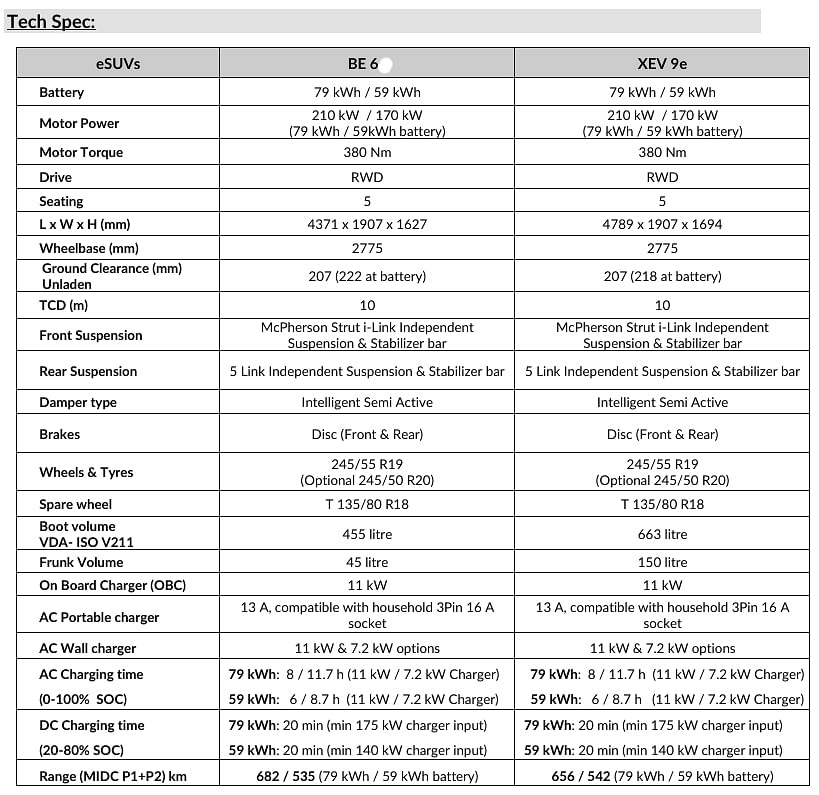

The two BEVs get 79kWh and 59kWh LFP Battery options. The 79kWh battery pack enables a certified range of 682km for the BE 6 and 656km for the XEV 9e with 79kWh battery pack. Charging from 20% to 80% takes just 20 minutes (with 175kW fast charger). The rear-mounted e-motor develops power of 210kW and delivers 380 Nm of instant torque to facilitate strong performance.

The 7-airbags-equipped BEV 6 and XEV 9e are also high on the safety quotient and both have aced the Bharat NCAP crash test with a 5-star rating.

Other platform-driven highlights include a semi-active suspension, best-in-class manoeuvrability owing to a variable gear-ratio steering system, an intelligent braking system and a high level of occupant comfort with a multi-link suspension.

The two new zero-emission SUVs also benefit from MAIA (Mahindra Artificial Intelligence Architecture), which is the advanced neural network that powers the BE 6 and XEV 9e. MAIA integrates state-of-the-art hardware and software to offer an intelligent, connected, and personalised driving experience, which is increasingly a sought-after product attribute for premium SUV and car buyers.

M&M’s EV manufacturing hub in Chakan is a fully-integrated, highly-automated manufacturing ecosystem that leverages over 1,000 robots.

M&M’s EV manufacturing hub in Chakan is a fully-integrated, highly-automated manufacturing ecosystem that leverages over 1,000 robots.

Hi-tech Chakan plant rolls out BE 6 and XEV 9e BEVs

In early January this year, Mahindra unveiled its new dedicated state-of-the-art manufacturing and battery assembly facility at its Chakan plant, a fully integrated ecosystem dedicated to producing Electric Origin SUVs. This EV manufacturing hub is a fully-integrated, highly-automated manufacturing ecosystem that leverages over 1,000 robots and multiple automated transfer systems.

Spread across 88,000 square metres, the EV-specific facility utilises a fully automated press shop, an AI-driven body shop and one of India’s most sophisticated robotic paint shops with state-of-the-art Dürr equipment to optimise quality and efficiency. The body shop has over 500 robots and fully automated transfer systems, all monitored via an IoT-based ‘Nerve Center’ for real-time process insights and end to end traceability.

The plant also adopts Industry 4.0 tech, AMRs (Autonomous Mobile Robot), and AGVs (Autonomous Guided Vehicles) for seamless material movement. The facility also houses a cutting-edge battery assembly operation. This is one of the world’s most compact battery manufacturing lines, and the fully automated plant integrates world-class manufacturing processes developed and implemented indigenously to produce/store/transfer high-performance, long-lasting batteries using industry 4.0 tech.

This facility is the result of the company’s allocation of Rs 4,500 crore out of the total Rs 16,000 crore planned in the FY2022–FY2027 investment cycle, which includes powertrain development, two product top hats including software and technology, and manufacturing capacity.

M&M has outlined a total manufacturing capacity of 90,000 vehicles per annum is being created its Automotive Division jointly with Mahindra Electric Automobile Ltd (MEAL) in Chakan in a phased ramp-up schedule by March 2025.

ALSO READ:

ALSO READ:

Revealed: A to Z component suppliers to Mahindra’s latest BEVs