Power Innovations International’s new line of DC fast chargers can accept a wide range of input voltages.

- The utility connection bottleneck has become the bête noire of the EVSE world. But sometimes the problem isn’t getting enough power, but rather getting the right kind of power—and sometimes the real bottleneck is getting the transformers and switchgear needed to work around these issues.

- Power Innovations International has a solution—its new line of EV chargers can handle a wide range of input voltages, eliminating the need for step-up transformers and 480 V switchgear, which can translate to big savings of time and money.

- Pii’s new chargers have several other features that customers have been asking for, including a modular architecture that’s designed to simplify installation and improve reliability.

There are three things everyone in the EV industry seems to agree on: (1) we need more charging infrastructure; (2) it needs to be more reliable; and (3) installation often takes much too long. Project delays very often have to do with getting a site connected to the grid, but it isn’t (always) the fault of local utilities—high demand for essential power equipment such as transformers and switchgear has created a shortage, and wait times can stretch into months or even years.

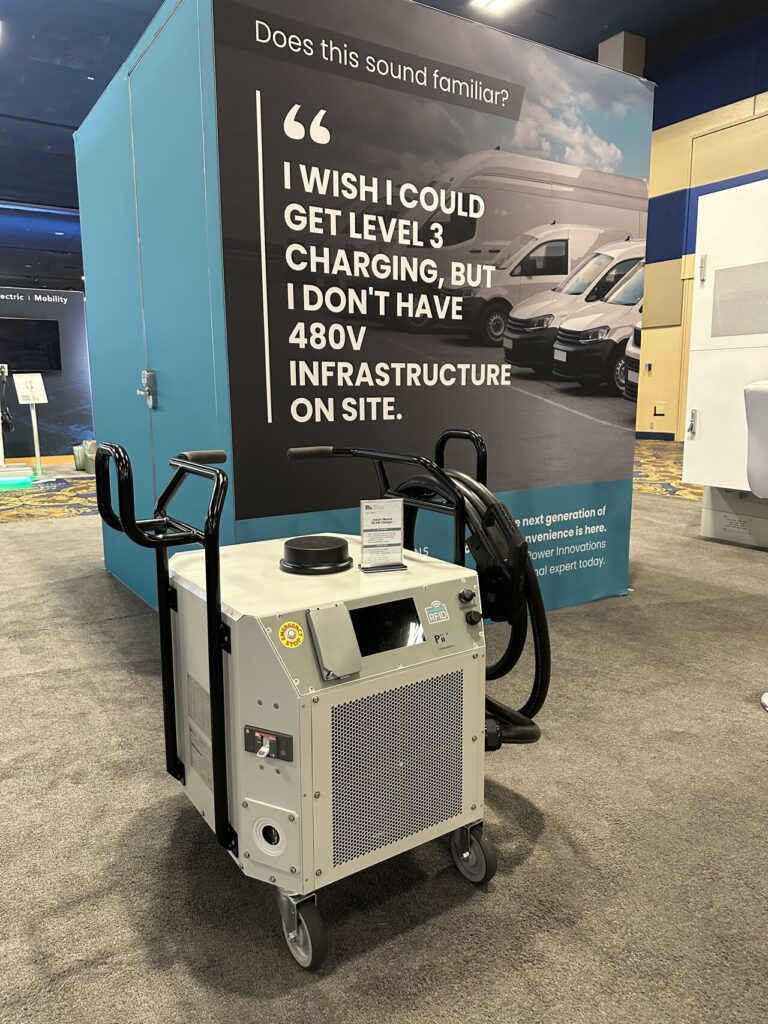

In addition to equipment shortages, many sites have problems obtaining the right kind of power. The majority of DC fast chargers on the market today require 480-volt, 3-phase power, instead of the 208 V and 240 V supplies found at many commercial and residential properties. And there are some areas in the US where 480 V is simply not available.

In addition to equipment shortages, many EV charging sites have problems obtaining the right kind of power.

Several EVSE industry pros have told us that this is a major bottleneck. CEO Alex Urist of XCharge, which makes battery-integrated chargers, raised the issue in an interview with Charged (see our Oct-Dec 2023 issue). If 480 V isn’t available at your site, you’ll need an extra piece of equipment called a buck-boost transformer to step the voltage up to what you need. Charging industry consultant Forest Williams told us that this item can cost thousands of dollars, and the lead time for obtaining the necessary switchgear can stretch to months.

EVSE manufacturer Power Innovations International (Pii) has a solution. The company recently introduced a line of EV chargers that can handle a variety of input voltages, including 240 V single-phase and 208 V/240 V three-phase—all in the same box, without derating the charger. This eliminates the need for step-up transformers and 480 V switchgear, which can translate to big savings of time and money.

Charged spoke with Nick Stone, Pii’s Product and Market Manager.

Charged: What’s the origin story behind your new EVFC line of chargers?

Nick Stone: Pii was started in 1997 as a small business in Utah, and developed a rugged, reliable type of UPS product, focusing on industrial applications. [Taiwanese electronics company] Lite-On acquired Pii in 2013. In the 2020-2021 timeframe, there was an opportunity to complement that business with what Pii can do. Lite-On has a number of Level 2 chargers, but Lite-On didn’t have a Level 3 charger. With DC fast charging, of course, we’re integrating power conversion to convert AC to DC, and that’s one of the core competencies that Pii offers.

At that time there were a lot of customer comments from some of the incumbents in the DC fast charger space. We listened to some of that feedback and tried to understand what customers were saying about their chargers. Of course, uptime is certainly imperative, but we wanted to add some other features.

We spent some time around 2022 developing some rectifiers that we use across our product lines, and leveraging the same power supply topology that Lite-On uses in the data center space. This gives us one million hours demonstrated MTBF [Mean Time Between Failures, a measure of reliability] within the data center. We wanted to take that same type of power supply topology that’s been demonstrated in mission-critical applications and integrate that into a DC fast charger.

One of the things that our firmware team does is a lot of embedded control. One of the competitors in this space builds a UL 508 A panel where your power supply and power meter are DIN rail-mounted, and you open it up and it’s a maze of wires. We wanted to take all the control and the power conversion that’s doing the auxiliary power and integrate that into one solution that sits on top of our power conversion. We spent some time developing that to where you take AC power coming into our power conversion block, measure the AC power, do all your low-voltage conversion—12, 24 and 48 volts for all the internal power needs and the auxiliary loads—bring that down to our power supplies, bring it back up through the high-voltage line, back through that same controller, and to the CCS1 output.

Charged: The low-voltage auxiliary loads are things like the video screen and the user interface?

Nick Stone: Yes. Our modem, the display, the buttons, the e-stop, the heat exchangers—all of those are coming from a central power supply that’s built in. There’s no need for a separate DIN rail power supply or a whole bunch of other wiring. Conversion of any type of AC voltage is a core competency that Lite-On has, and we integrated that into our overall design. We don’t have external wires come and go to the power supply, then come out and feed all these loads—we’re doing it all in an integrated, clean solution.

Now, of course, we need an enclosure, we need thermal management, environmental protection, a display, some type of user interface. That’s where we spent some time listening to customers and installer partners. They were saying, “I don’t like to do filter replacements.” Okay, we will integrate that into our design. We will have a way to do thermal management that requires no maintenance.

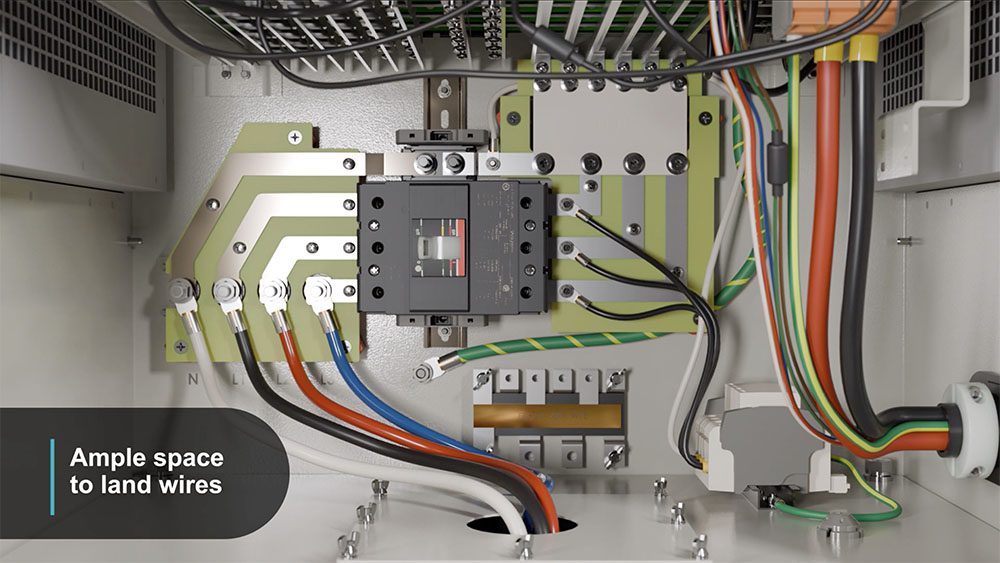

They were saying, “I need this thing to be easy to install.” How do we do that? One key is having a very wide space to land your cables, so you can do any type of configuration when you’re doing the installation. With a lot of space, you don’t need tweezers. Even if you’re doing 60 kilowatts, 240 single-phase, for instance, your cable bending space, you could struggle with that during the installation.

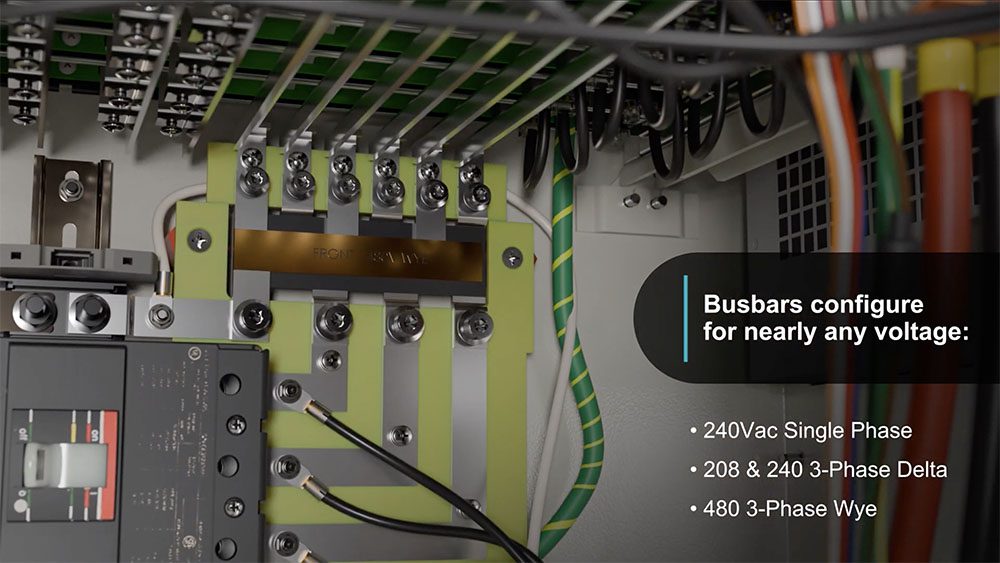

That was one of the key messages that we heard. Another was, when we’re in existing infrastructure, they don’t always have 480-volt power available. They may only have 208, 240 single-phase or delta, so they have to buy a step-up transformer. That’s another pain point that we heard: “I can buy a charger with maybe six months of lead time, but I have to wait two years to get my transformer.” We came up with a way, which we have a patent pending on, to accommodate any standard US installation voltage out there. We can do 208, 240 delta, 240 single-phase, 480 delta [a form of three-phase that doesn’t have a neutral], 480 wye, all in the same charger.

We came up with a way, which we have a patent pending on, to accommodate any standard US installation voltage out there. We can do 208, 240 delta, 240 single-phase, 480 delta, 480 wye, all in the same charger.

Accommodating the available power can help speed up getting the chargers into the ground. If you’re looking at a hotel or a car dealership or a gas station, they’re probably not going to be installing ten DC fast chargers, so they don’t want to get that additional transformer. In some cases, you would have to pour a pad, get a primary and secondary disconnect, and depending on who owns that station, you might have to get a meter socket to branch off power. There’s a lot of different variables, and we have seen instances where doing that can double your project cost.

Charged: Our Chloe Theobald spoke to your Global Sales Manager Tim Rees at the 2024 ACT Expo, and he explained that Pii’s chargers are based on a modular power architecture that can keep them delivering electrons even if individual modules fail.

Nick Stone: It’s similar to a data center type of architecture. If a power supply goes down, it doesn’t take the rest of the system down. For example, we have nine modules in our 30 kW charger. If one does go down, the other eight are still operational. You’re running at 26.7 kilowatts instead of 30, but your whole station doesn’t go down. And to replace a power supply, the module slides right in and out in a matter of seconds. Any other type of charger, you have to take that whole 30 or 40 or 50 kW block out, and it’s a pretty serious level of effort. For us, we ship out another module, you take the top off, there’s a little tab that you pull out, slide another one in, and you’re back up and running at full capacity.

Charged: Your chargers can accept not only a wide range of voltages on the input side, but on the output side too, so they can already accommodate the new EVs that are moving to 800-volt systems.

Nick Stone: Correct. We have the dual drivetrain in our rectifier that can do that. Some of the first Hyundai/Kia 800-volt vehicles out there, we’ve already been charging those for a couple years now. We know that’s where the industry’s heading, because you can lower your current and increase your overall power.

Charged: It all seems like a no-brainer. You’ve got a charger that can eliminate the need for a transformer. Why isn’t every EVSE manufacturer offering that?

Nick Stone: I’ll say a couple things. One, we’re one of the only ones that are vertically integrated in this space, so we are able to configure our power supplies to the application that we have. And looking at the power supply topologies that are used in the data center space, we have to have a wide input range to accommodate that market segment. Also, the way we’ve arranged our rectifiers within what we call our power shelf is a proprietary arrangement, and that’s something we do have a pending patent on.

Now, there are a few manufacturers that can take a 240 delta input, but you’re derating the amount of power. For instance, if you go to that 30-kilowatt charger, it’s 30 kilowatts if you feed it 480 three-phase. You can apply 240 to it, but you may derate to maybe 22 or 24 kilowatts of power. We’re the only ones that we’ve seen that can take any of those different input voltages without derating the amount of power. So, if you buy 30 kilowatts or 60 kilowatts or 120 kilowatts, you get what you bought.

Charged: And whoever’s installing the chargers can easily choose the input voltage that they need.

Nick Stone: Yes. It’s not something you have to do with firmware or anything like that, it’s actually a mechanical way that we do that. Inside of the charger there’s this big open space for ease of installation, and in this area are what we call configurable busbars. This is something that is smaller than the palm of your hand. It’s a very easy process. All three of these are available in every charger that we sell, so when the electrician or the installer sees what input voltage they have available, they simply pick the appropriate voltage. It’s printed right on the front of the busbar.

Charged: Considering that this can save money and time, and increase reliability, do you foresee that your competitors are going to start doing this too?

Nick Stone: I think they’ll certainly take notice. When we were at ACT doing our initial market launch of the product, there were a number of competitors that came by to learn about what we’re doing. The way we’ve done it though, I think we have enough protection there for our IP for them not to do it the same way, and it will then take another couple years for them to do it a little bit differently.

Charged: So you’ve got a first-mover advantage that’s going to last you for a couple years, hopefully.

Nick Stone: We believe so, yes. There’s one additional featurethat I haven’t mentioned yet. Our standard rectifier today uses AC input voltages, but it is capable of taking a DC input voltage as well, so we can now take inputs from a battery source or a hydrogen fuel cell input. So, we’re looking at these other applications—if you’re in the portable power space serving applications such as events or movie studios, those are some of the additional applications that we are working with partners to expand the application set, because we can do DC input.

This article first appeared in Issue 71: January-March 2025 – Subscribe now.