A 3D printed safety device has helped save the life of an NTT INDYCAR SERIES driver.

Josef Newgarden was involved in a high-speed collision with Louis Foster during the recent Bommarito Automotive Group 500 race at the World Wide Technology Raceway in Madison Illinois.

Newgarden, a two-time INDYCAR SERIES champion, collided with Foster on lap 131, sending his No. 2 Chevrolet airborne. The Team Penske driver landed upside down, before skidding along the tarmac in a shower of sparks.

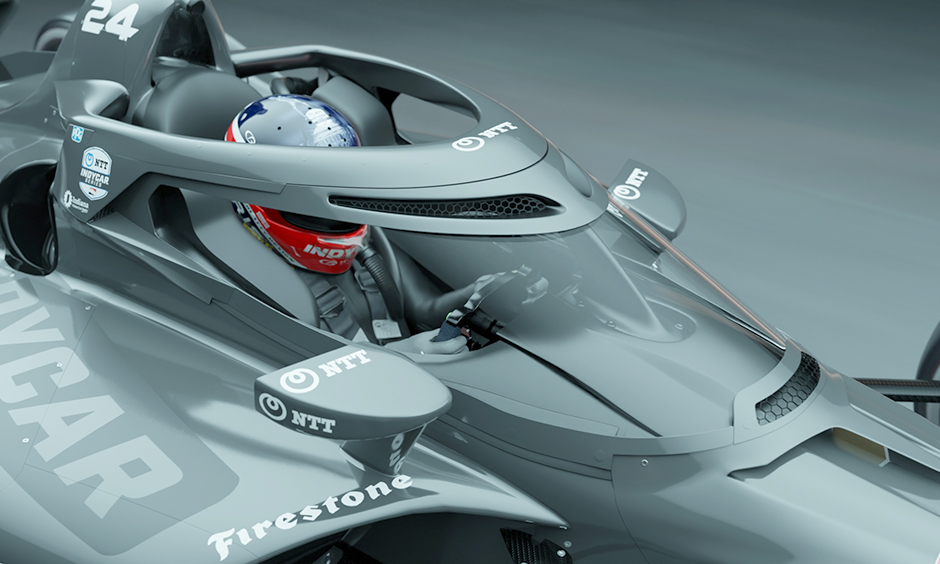

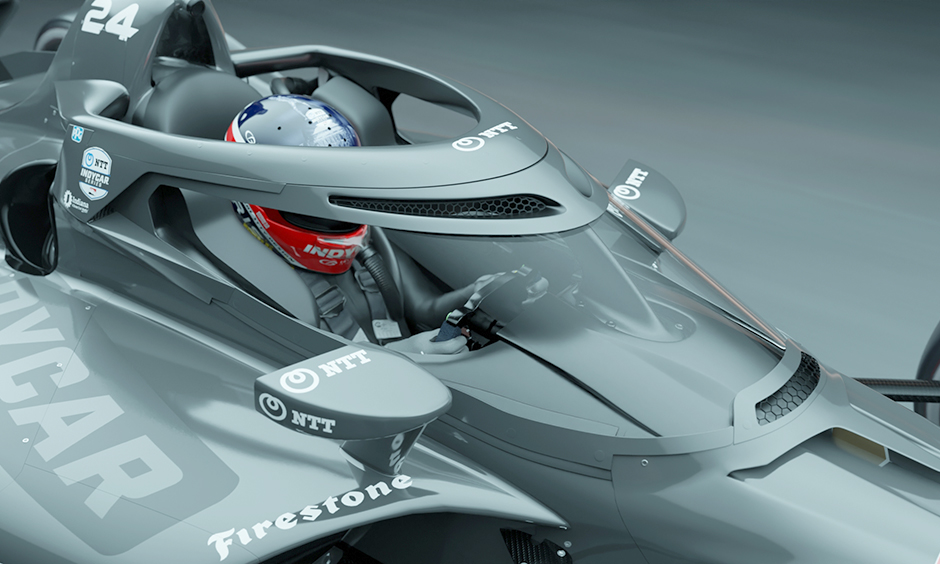

After being righted by the American Medical Response Safety Team (AMR), Newgarden was able to climb out of the vehicle, escaping serious injury. The brunt of the force was absorbed by his Aeroscreen, a 3D printed cockpit safety device that was first introduced in 2020 and updated with a more lightweight design in 2024.

Foster, a Rookie driving for Rahal Letterman Lanigan Racing, spun out with major damage to his Honda-powered Dallara chassis. He also walked away largely unscathed after his Aeroscreen deflected a hail of debris.

The device is a mandatory feature on all NTT INDYCAR SERIES cars for road and street course races. It features a 3D printed titanium frame, engineered by Red Bull Advanced Technologies (RBAT) and manufactured by the Austrian mechanical systems company Pankl.

This frame is paired with a laminated polycarbonate ballistic windscreen, developed by aircraft windshield specialist PPG Industries. Together, they form a protective barrier similar in function to the Halo crash-protection system used in Formula 1 since 2018.

3D printed Aeroscreen enhances IndyCar safety

Prior to its 2020 debut, several manufacturing techniques were explored for Aeroscreen production.

The first design was reportedly made using titanium casting. However, lengthy production lead times made it unable to meet the tight deadline ahead of the 2020 INDYCAR season opener. Consequently, Pankl was chosen to fabricate the frame using its EOS M400-4 laser powder bed fusion (LPBF) 3D printer.

The original Aeroscreen (Version 1.0) featured a frame constructed from five 3D printed sections welded together. In pre-race testing, it withstood forces equivalent to 34,000 pounds, while the ballistic windscreen was tested to endure the impact of a 17.3-pound object traveling at 220 mph. The device made its on-track debut during testing at Indianapolis Motor Speedway in October 2019 and was officially introduced in competition in February 2020.

Last year, INDYCAR introduced Version 2.0, a lighter screen designed to enhance performance and comfort. It includes integrated air vents to improve cockpit cooling, along with a front-facing rubber 3D printed to help prevent hand injuries during a crash.

The updated design first hit the track during the 2024 Acura Grand Prix in Long Beach. Its weight was trimmed from 18.9 lbs on Version 1.0 to 14.5 pounds, while retaining the same strength as the original. This is thanks to the new, topologically optimized 3D printed titanium frame.

Combined with the ballistic windscreen, the updated Aeroscreen offers a total weight reduction of 11.1 pounds, reducing downforce by approximately 35 lbs.

Enhanced cooling plays a critical role in boosting driver performance, according to Tino Belli, Director of Aerodynamic Development for the NTT INDYCAR SERIES. She noted in a press release that drivers consistently emphasized the need for better airflow, as their body temperatures often exceed 100°F during races. Racing teams can also install an optional filter to help keep dust out of the cockpit.

Additive manufacturing accelerates motorsport

3D printing is not new in motorsport. Racing teams have long leveraged additive manufacturing to provide an edge on the track. For example, the Oracle Red Bull Racing F1 Team is a keen adopter of advanced technologies, including 3D printing.

In an interview with 3D Printing Industry, Ian Handscombe, Head of Quality Engineering at Red Bull Racing, claimed: “I don’t think we will continue to be on track unless we embrace [3D printing].”

Technical partnerships with companies play a key role in supporting additive manufacturing at Red Bull Racing. So much so, ahead of the 2025 F1 season, Red Bull extended its long-term collaboration with manufacturing technology company Hexagon. This builds on an 18-year-long relationship with Hexago as the team’s exclusive metrology partner.

The Swedish firm supplies Red Bull with 3D scanners and digitalization capabilities. This technology allows the F1 stalwart to make over 20,000 car design changes each season. According to Hexagon, metrology technology has helped cut faults by over 50% over the past two years.

Elsewhere, BWT Alpine F1 team leverages 3D Systems’ SLA and SLS 3D printers to support Formula 1 wind tunnel testing. The racing team reportedly 3D prints 25,000 parts annually to reduce research and development time and improve on-track performance.

Similarly, the McLaren F1 racing team has a long partnership with 3D printer OEM Stratasys. Dating back to 2017, this collaboration has seen McLaren leverage five Stratasys Neo 800 to support aerodynamic wind tunnel parts. Elsewhere on the grid, Alfa Romeo Racing made extensive use of Additive Industries’ MetalFAB1 3D printer during the 2021 season. The team 3D printed lightweight racing car components, which cost 90% less than those produced using traditional methods.

Who won the 2024 3D Printing Industry Awards?

Subscribe to the 3D Printing Industry newsletter to keep up with the latest 3D printing news.

You can also follow us on LinkedIn, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows Josef Newgarden’s INDYCAR crash. Photo via NTT INDYCAR SERIES.