Japanese automotive giant Toyota’s production engineering group is accelerating innovation on the factory floor through its collaboration with 3D printer OEM Stratasys. By integrating advanced additive manufacturing (AM) technology directly into daily operations, Toyota equips its teams to transform tools, fixtures, and jigs from initial concept to fully functional prototype within a single day. This partnership allows engineers to iterate rapidly, respond to evolving production requirements, and implement process improvements with unmatched efficiency.

“Additive manufacturing has transformed how our teams collaborate and innovate,” said Lisa Bednar, Group Manager, Production Engineering at Toyota North America. “Instead of sending an idea out and waiting weeks for a part, we’re building it ourselves, refining it the same day, and getting it into production faster. It’s not just about speed — it’s about giving our people the tools to think differently and act immediately.”

Rich Garrity, Chief Industrial Business Officer, Stratasys, emphasized that Toyota sets the standard for how manufacturers use AM to deliver real operational impact. “Their teams are using our technology to move faster, adapt on the fly, and build safer, more efficient production environments. We’re proud to support a partner that’s turning bold ideas into real-world, measurable improvements on the factory floor.”

A Decade of Partnership and On-Site Innovation

Over more than ten years of collaboration, Toyota engineers have gained access to industrial-grade Stratasys 3D printers and high-performance polymers engineered to endure demanding factory conditions. These capabilities reduce reliance on external suppliers and long lead times, allowing frontline teams to produce prototypes and functional parts on-site.

Toyota currently deploys a suite of Stratasys printers across its North American facilities—including the F3300, F900, Origin One, F770, Neo800, H350, F370, J850, and Fortus 450mc—to produce factory tooling, end-use parts, and functional prototypes.

Earlier this year, Dallas Martin spoke to 3D Printing Industry about how Toyota uses 3D printing in the automotive sector.

Transforming Efficiency, Safety, and Workforce Innovation

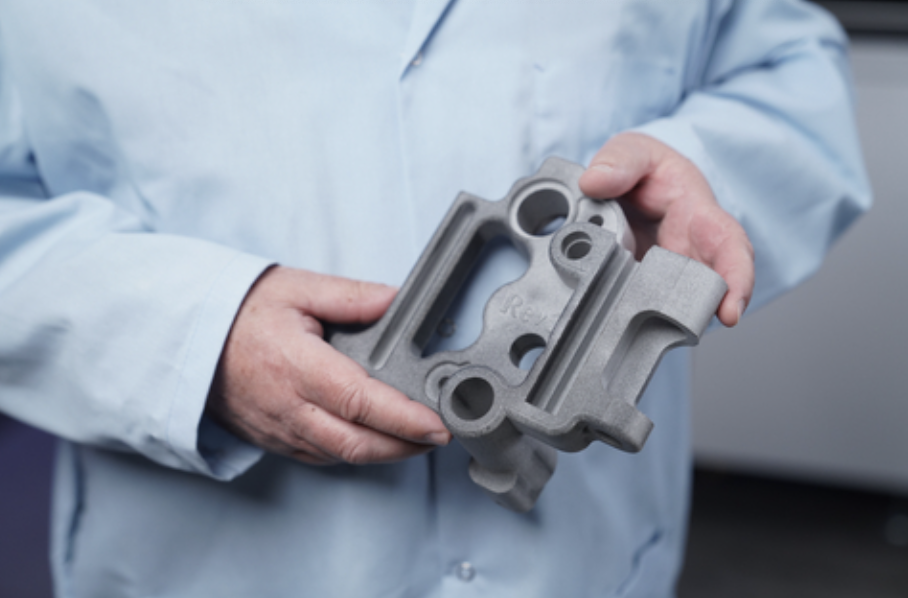

Much of Toyota’s additive manufacturing progress comes from the Toyota Add Lab, the company’s in-house AM center launched in January 2023 to accelerate R&D and factory innovation. Through the Add Lab, Toyota engineers have redesigned a door assembly fixture, producing a lighter, more ergonomic tool on-site in just a few days. They also developed a custom window alignment jig that reduced a multi-person task to a single-person operation, enhancing both safety and efficiency.

“Sometimes we start with nothing more than a sketch on paper or an idea in our heads,” said Dallas Martin, Additive Manufacturing Engineer at Toyota North America. “We can model it digitally and hold a working part in our hands the very next day. That speed lets us move quickly, implement safer solutions, and continuously iterate to improve our processes.”

Additive Manufacturing for Automotive Applications

The role of 3D printing in automotive manufacturing is growing, as car makers target material, cost, and time savings for prototyping, tooling, and end-use parts.

In March, Japanese automotive manufacturer Honda announced it is working to increasingly integrate metal additive manufacturing into its development and production processes. It already 3D prints metal parts in house using LPBF technology, including systems from Nikon SLM Solutions. The firm claims to have accumulated AM expertise by optimizing parameters, recording material deposition to assess melting state, and monitoring temperature and laser power. Process simulation technology is also used to predict and mitigate potential deformations and improve the dimensional accuracy of its parts. Honda noted that metal 3D printing allows it to fabricate complex shapes that are impossible to achieve with conventional casting and forging techniques.

Elsewhere, Ford Motor Company, a global automotive manufacturer established in 1903, announced it is using 3D printing to prepare for its first F1 race in two decades. Set to compete during the 2026 season, Ford has already produced over 1,000 3D printed car parts at its additive manufacturing labs, including cold plates for batteries and cooling plates for other systems. These will feed into the race cars’ combustion engine and hybrid technology.

Join industry leaders at AMA: Energy on September 17th and AMA: Automotive & Mobility on October 1st.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows a 3D printed transmission test tool, designed in the Toyota ADD Lab and printed on the Stratasys H350 using PA12 material. Photo via Stratasys.