Fraunhofer Institute for Laser Technology (ILT), a German research organization specializing in laser-based manufacturing, and MacLean-Fogg, a U.S. supplier of engineered metal components, have produced a large die casting tool inlay for Toyota using laser powder bed fusion (PBF-LB/M). The project marks the first successful demonstration of large-volume tools with conformal cooling, made possible by a newly developed tool steel called L-40. A hybrid mold insert for the Toyota Yaris Hybrid transmission housing was manufactured by combining conventional preforms with additively built structures, reducing production time and enabling more complex cooling designs.

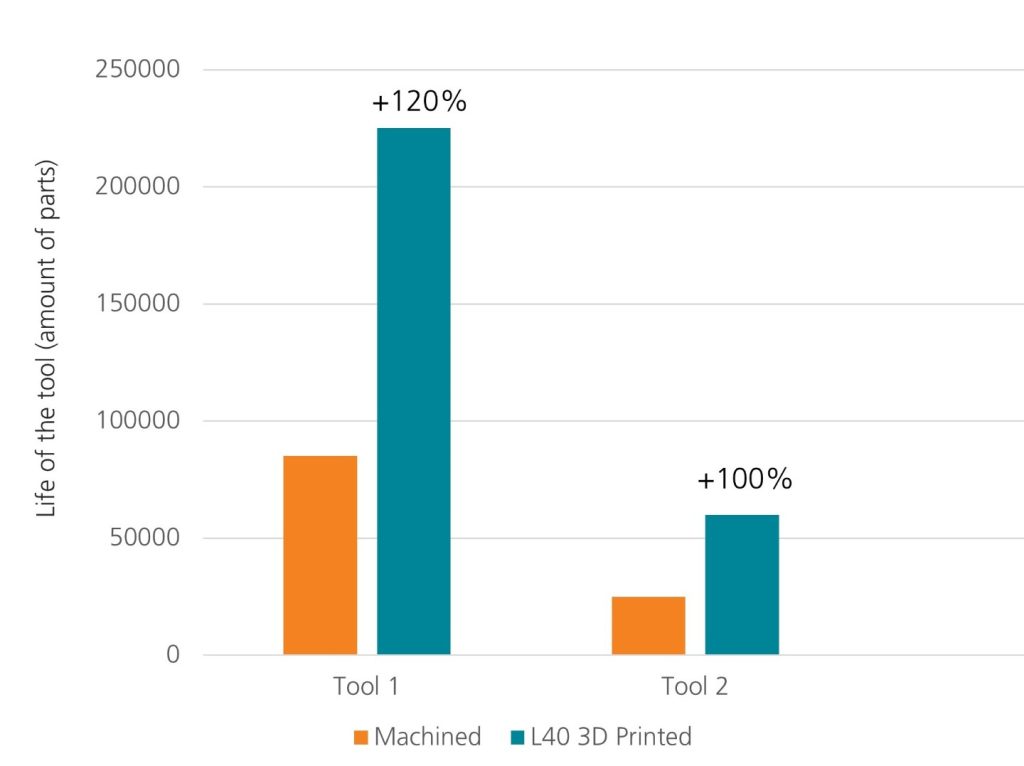

Automotive manufacturers are under pressure to consolidate parts into fewer but larger aluminum components as electrification and cost competition reshape vehicle platforms. This shift places higher demands on die casting molds, which must resist extreme thermal and mechanical stresses while adapting quickly to design changes. Traditional machining and tool steels such as H11, H13, or M300 struggle to deliver these requirements at scale, leading Fraunhofer ILT and MacLean-Fogg to focus on new machine concepts and materials. Toyota, already using smaller additively manufactured molds in series production, has reported significantly longer tool life compared to conventional inserts, with service lives up to four times greater.

Niklas Prätzsch, Group Leader for LPBF Process Technology at Fraunhofer ILT, explained: “To overcome these limitations, we need a new generation of machines and materials specifically tailored to the requirements of large-format HPDC tools. It was precisely this combination that was the subject of the latest changes we have implemented.”

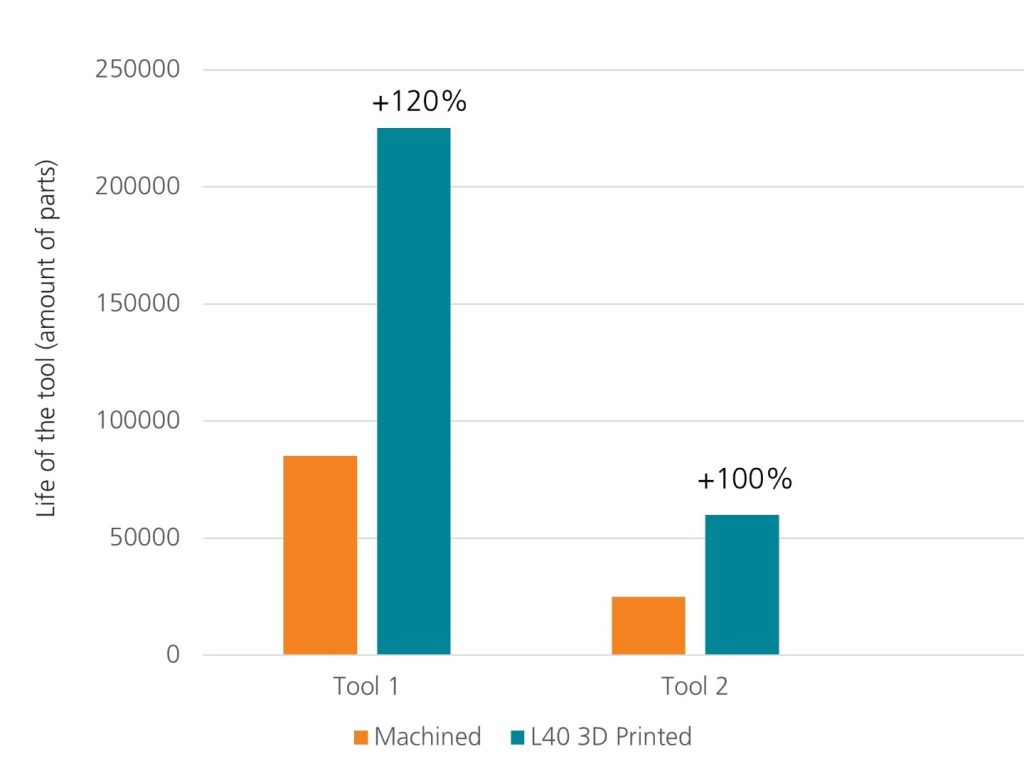

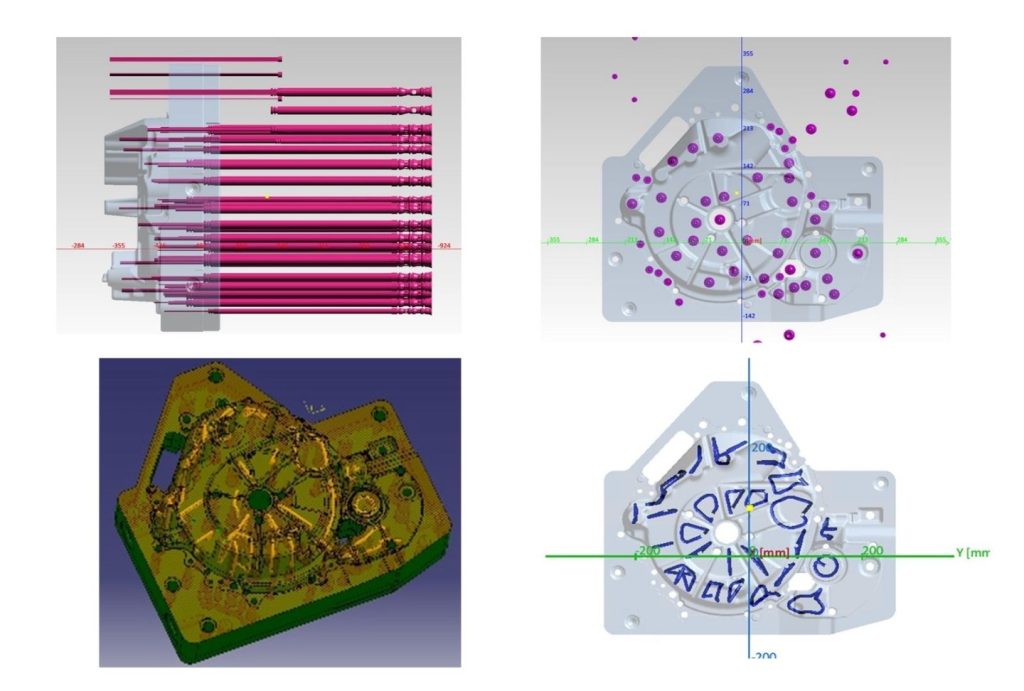

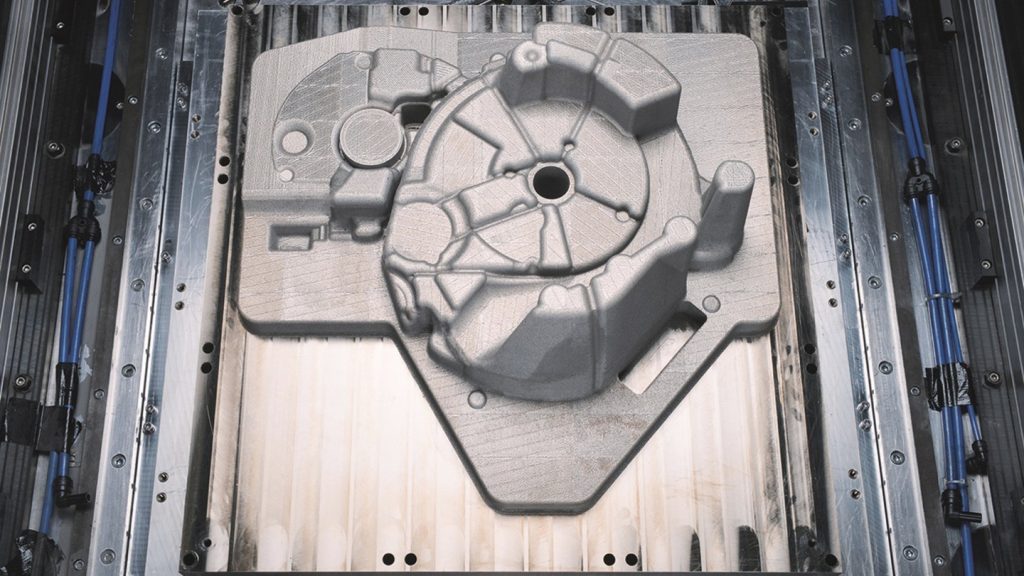

Fraunhofer ILT designed a gantry-based five-laser PBF-LB/M machine with a build chamber measuring 1,000 × 800 × 350 mm³. Unlike fixed-bed systems, the machine employs a movable processing head with local shielding gas guidance, keeping parameters such as gas flow speed and laser deflection angle constant as the build area scales. This approach enabled construction of inserts exceeding 20,000 cm³, including the Toyota inlay with a bounding box of 515 × 485 × 206 mm³. A heated substrate reaching 200 °C reduced temperature gradients during the build, lowering the risk of residual stress and cracking that typically occur in large geometries.

Material development was equally critical. MacLean-Fogg created L-40, a steel tailored for additive processing of high-pressure die casting tools. Compared to established alloys, L-40 showed a markedly lower tendency to crack during both printing and heat treatment. In the as-built state, the alloy achieved hardness of 48 HRC, tensile strength of 1,420 MPa, and notched impact strength above 60 J. Tests confirmed stability in complex geometries, including round and overhanging cooling channels, where conventional steels often fail.

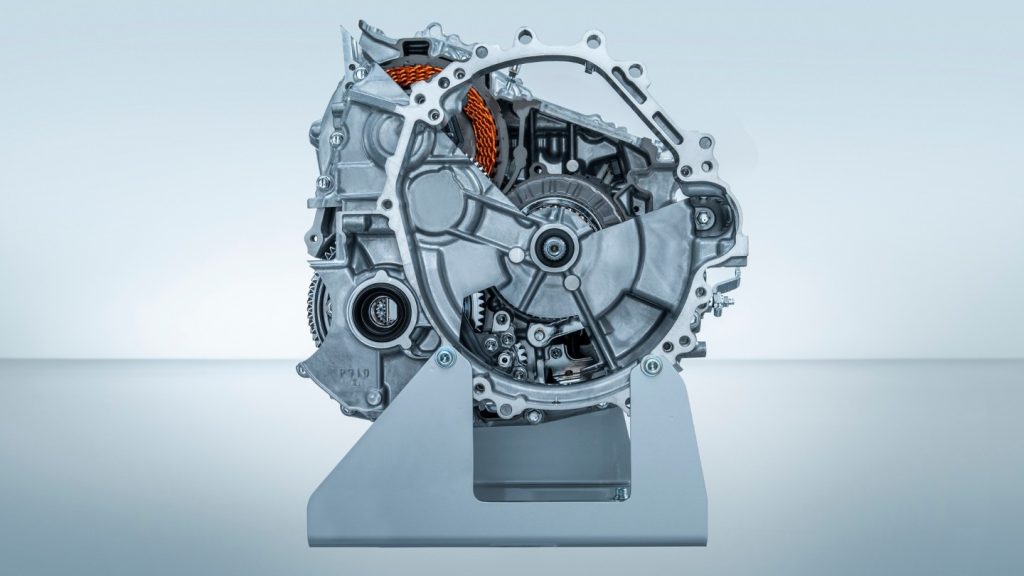

For Toyota’s gearbox housing, the project team adopted a hybrid production method. A preform with vertical cooling channels was first manufactured conventionally, after which conformal channels were additively built on top. This required precise machine calibration to ensure accurate alignment and reliable bonding between the two sections. After completion, the insert was stress-relief annealed and its functional surfaces were milled conventionally. High dimensional accuracy in the additive base body meant only minimal finishing was needed without further material input.

Harald Lemke, Director of Product Management at MacLean-Fogg Component Solutions, said: “With L-40, we set out to break the limits of additive manufacturing for hot and cold forming tools in general and die casting tools specifically. This project proves that it’s possible to produce large, complex and highly durable inserts technically and gives clear milestones to reach to be economically attractive. Additive manufacturing is ready to take on real industrial scale challenges.”

The conformal cooling network within the insert was designed to temper thermally stressed zones of the mold. By lowering local temperature peaks, the system reduces thermomechanical wear and extends service life. Earlier studies showed additive molds lasting up to four times longer than conventional H13 inserts, and the current project scaled these advantages to larger applications. For manufacturers, this means fewer tool replacements, lower costs, and faster response times to new design requirements.

Beyond automotive die casting, the process chain is applicable to other areas requiring durable tools with complex cooling. Potential extensions include plastics processing and composite forming, where limited batch sizes and high thermal loads also drive the need for more resilient molds. With giga casting and electrified vehicle platforms raising tooling demands further, scalable additive systems offer a path toward faster, more adaptable, and longer-lasting production tools.

Limited spaces remain for AMA:Energy 2025. Register now to join the conversation on the future of energy and additive manufacturing.

Ready to discover who won the 2024 3D Printing Industry Awards?

Subscribe to the 3D Printing Industry newsletter and follow us on LinkedIn to stay updated with the latest news and insights.

Featured photo shows the additively manufactured aluminum die-cast tool is part of the tool for the transmission housing of the Toyota Yaris hybrid vehicle. Photo via Toyota Europe.