Nissan’s big bet on all-solid-state EV batteries might just pay off. The Japanese automakers moved one step closer to bringing next-gen battery tech to market, promising to double driving range, shorten charging times, and improve overall efficiency.

When will we see Nissan’s all-solid-state EV batteries?

You may have heard all-solid-state batteries (ASSBs) referred to as the “holy grail” of EV batteries, due to claims that they can double driving range and cut charging times by one-third compared to current lithium-ion batteries.

So far, solid-state and ASSBs have shown promise in lab tests, and a few companies are even testing them on the road.

Nissan is one of the many automakers, startups, and other companies racing to be the first to introduce all-solid-state batteries.

After securing a new partnership with US-based LiCAP Technologies last month, Nissan took another big step toward launching all-solid-state batteries on a mass scale.

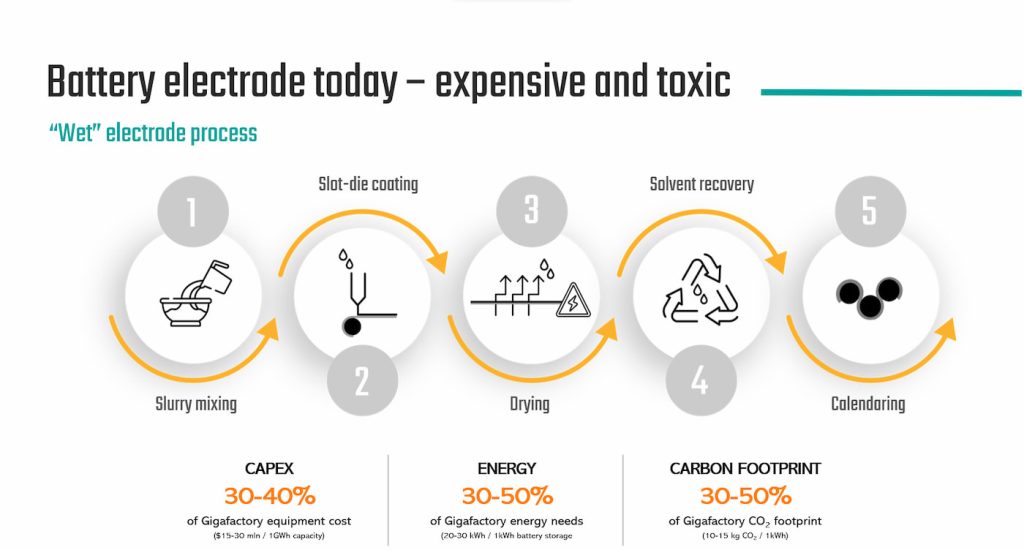

One of the biggest hurdles automakers are facing is producing the new tech on a mass scale. For one, it’s costly to build the manufacturing lines and equipment, and the process of actually assembling the batteries takes too long.

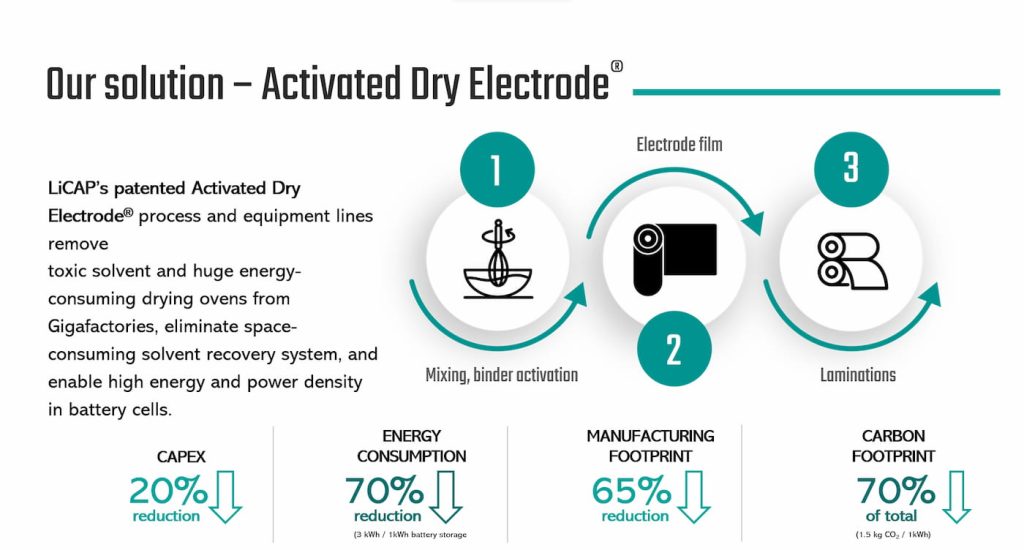

Nissan believes it has the answer. Using LiCAP’s proprietary Activated Dry Electrode technology, Nissan is using a “dry electrode” production process.

Since the process doesn’t use a solvent to coat the surface, it eliminates the need for drying while also enabling more efficient ion movement.

Nissan claims to now have “significant advantages” in all-solid-state EV battery production and performance. The company said that using LiCAP’s tech will significantly reduce manufacturing costs with minimal environmental impact.

According to Nikkei, Nissan took another big step toward commercializing the new battery tech after prototype cells reached performance targets set for mass production.

Nissan opened its first pilot line for all-solid-state EV batteries in January at its Yokohama plant in Japan. The company aims to achieve a cost of $75 per kilowatt-hour, about 30% below the average battery pack price in 2024.

The Japanese automaker plans to launch its first vehicles powered by all-solid-state EV batteries by fiscal year 2028.

Electrek’s Take

Will Nissan’s big bet on ASSBs pay off? Japanese automakers, including Toyota and Honda, are also racing to introduce promising battery tech to compete with brands from China, such as BYD and CATL, which are already dominating global sales.

According to SNE Research, CATL and BYD alone accounted for nearly 55% of global battery sales in the first eight months of 2025.

South Korea’s LG Energy Solution, SK On, and Samsung SDI accounted for 16.8% of the market, while Panasonic, the only Japanese company to rank in the top ten, accounted for just 3.7%.

After announcing a new partnership with Sumitomo Metal Mining Co. earlier this month to mass-produce cathode materials, Toyota said it aims to “achieve the world’s first practical use of all-solid-state batteries in BEVs” as early as fiscal year 2027.

Honda invested 43 billion yen ($281 million) to establish one of the largest all-solid-state battery production lines. It also opened its first ASSB pilot line in January.

CATL and BYD are reportedly aiming to launch ASSBs around 2027, with mass production closer toward the end of the decade. Volkswagen affiliate Quantumscape looks to begin mass production as early as 2026.

China’s SAIC Motor also plans to begin mass-producing all-solid state batteries next year. SAIC already launched the new MG4 earlier this year, deeming it “the world’s first mass-produced semi-solid-state” electric vehicle.”

Which company will be the first to produce next-gen battery tech at scale? We will likely find out very soon. Stay tuned.

FTC: We use income earning auto affiliate links. More.