India’s commitment to achieving a Net Zero emission target by 2070 and to reducing carbon emissions by one billion tonnes by 2030 underscores the critical need for a transition to electric mobility. This transition is a key technological leap that will propel India towards achieving global climate change targets.

With an ambition to achieve a 30% electric vehicle (EV) market share by 2030, EV adoption in India is rapidly gaining momentum. In 2025, EV penetration in India reached 8% of total automobile sales, with electric two-wheelers (e-2Ws) contributing about 56% of total EV registrations. Electric three-wheelers (e-3Ws), electric buses (e-buses), and electric four-wheelers (e-4Ws) have also achieved significant market traction, driven by favourable economics, regulatory support, and rapid expansion of fast-charging infrastructure.

The growth of electric Heavy-Duty Vehicles (e-HDVs)—trucks and buses—remains low. There is a need to establish robust, safe, reliable, accessible, and affordable charging infrastructure to accelerate this momentum and enable faster adoption of EVs, including e-HDVs, in the country.

High-capacity EVs such as trucks and buses are fundamentally different in terms of charging requirements compared to 2Ws, 3Ws, or 4Ws, where owners often prefer to install personal charging points at home, while public charging points are increasingly being made available through Charge Point Operators (CPOs) across the country.

In the case of heavy-duty vehicles, there is a need to move towards fast-charging technologies to reduce charging time and infrastructure costs, while also optimizing battery capacity. Dual-gun charging, pantograph charging, catenary charging, wireless charging, megawatt-hour charging, and battery swapping are emerging technologies that are evolving to address these needs. This article discusses these different charging technologies and their application in India.

GoI Schemes Promoting EVs

The PM Electric-Drive Revolution in Innovative Vehicle Enhancement (PM E-DRIVE) Scheme, launched in 2024 with an outlay of ₹10,900 crore, offers incentives to accelerate the adoption of EVs and to establish charging infrastructure. It proposes the installation of 48,400 fast chargers for e-2Ws/3Ws, 22,100 fast chargers for e-4Ws, and 1,800 fast chargers for e-buses across India, with an outlay of ₹2,000 crore. Further, ₹4,391 crore has been earmarked for the procurement of over 14,028 e-buses by State Transport Undertakings (STUs) and public transport agencies, providing significant subsidies of up to ₹35 lakh per standard bus.

The PM-eBus Sewa Scheme aims to augment bus operations through the deployment of 10,000 electric buses under a PPP model. This initiative is expected to enable the deployment of more than 38,000 electric buses during the period from FY 2024–25 to 2028–29 through a Gross Cost Contract (GCC) model and a Payment Security Mechanism (PSM) for STUs, with operational support extending up to 12 years from the date of deployment.

To bridge the gap in research and development, the Department of Science and Technology (DST), Government of India, launched various initiatives such as the MAHA EV Mission under the aegis of the Anusandhan National Research Foundation (ANRF), which focuses on the development of key EV technologies to reduce dependency on imports and promote domestic innovation. DST has also launched another program known as EVolutionS (Electric Vehicle Solutions led by Startups for component manufacturing), aimed at supporting EV startups in translating proof-of-concept technologies and prototypes into commercially viable products.

High Power Charging Technologies

High-power charging is essential for e-buses and e-trucks, with varying requirements based on vehicle type and usage patterns. E-buses require different charging strategies depending on their routes and battery capacities: city buses may need overnight charging, while long-distance buses may require a combination of destination charging and fast opportunity charging. Conversely, the freight sector demands rapid charging solutions to maximize vehicle uptime and payload capacity.

The selection of charging systems is crucial and varies across several technologies, each with distinct configurations and advantages. These include:

Dual-Gun Charging

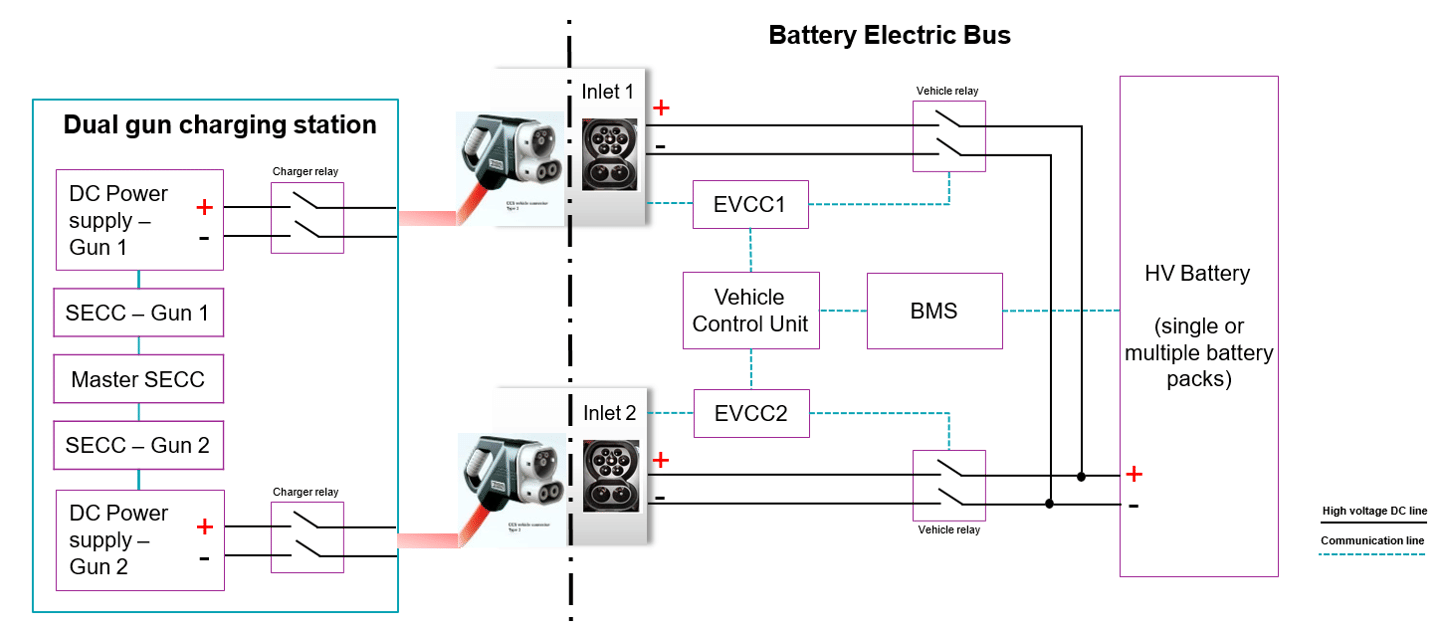

As the name suggests, this technology uses two guns, accommodating power delivery requirements of up to 500 kW. Unlike the Combined Charging System (CCS) standard involving a single gun, which typically provides power up to 250 kW or 350 kW, dual-gun chargers mitigate the need for costly infrastructure upgrades by delivering increased power through two separate outlets. This configuration enables faster charging by effectively doubling the power delivery rate, thereby halving the charging time. Other benefits include:

As the name suggests, this technology uses two guns, accommodating power delivery requirements of up to 500 kW. Unlike the Combined Charging System (CCS) standard involving a single gun, which typically provides power up to 250 kW or 350 kW, dual-gun chargers mitigate the need for costly infrastructure upgrades by delivering increased power through two separate outlets. This configuration enables faster charging by effectively doubling the power delivery rate, thereby halving the charging time. Other benefits include:

(a) compatibility, as it utilizes the same communication protocols and components as single-gun systems;

(b) the use of established standards such as CCS, which are widely adopted and tested globally; and

(c) operational resilience, as dual-gun chargers can revert to single-gun charging in the event of a failure, ensuring that the vehicle’s high-voltage battery is not left uncharged. Dual-gun charging is already in practice among several players.

From an infrastructure and grid integration perspective, managing power and cooling systems involves complex coordination. Additionally, simultaneous high-power charging of multiple buses can significantly impact local grid stability, necessitating careful grid balancing to prevent disruptions.

Catenary Charging

Instead of a conventional ground-based charging facility, this system employs an overhead fixed line with a vehicle-mounted pantograph. This is similar to electric railway systems, where locomotives draw power from overhead equipment (OHE), but adapted for heavy-duty road vehicles.

Catenary systems for trucks utilize two overhead wires installed along designated routes, with battery-electric trucks equipped with a pantograph mounted on the vehicle’s roof to draw current while in motion. The system can deliver up to 500 kW of power at voltages up to 1,500 V DC.

By eliminating lengthy downtime at charging stations, catenary systems significantly enhance operational efficiency and driver productivity. However, multiple challenges—including the absence of Indian standards specific to catenary systems and the significantly higher cost of OHE infrastructure—complicate the adoption of this technology. In addition, required modifications to vehicle designs further increase complexity.

Inductive Charging

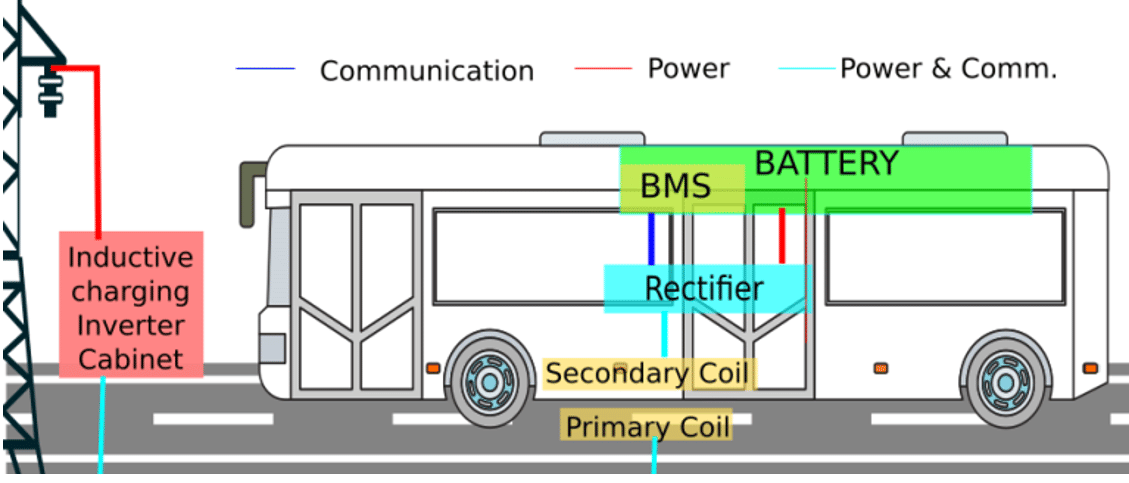

In this method, power transfer takes place through magnetic resonance coupling via inductive loops buried in the roadway. These loops generate a magnetic field that wirelessly supplies energy to e-buses. This contactless energy transfer, which is approximately 90% efficient, involves an electric current flowing through conductors (charging plates) embedded in the road to generate a magnetic field.

In this method, power transfer takes place through magnetic resonance coupling via inductive loops buried in the roadway. These loops generate a magnetic field that wirelessly supplies energy to e-buses. This contactless energy transfer, which is approximately 90% efficient, involves an electric current flowing through conductors (charging plates) embedded in the road to generate a magnetic field.

The system consists of a primary coil in the road connected to the power grid and a secondary coil fitted beneath the bus. Inductive charging offers two distinct capabilities tailored to different needs:

(a) low-power static charging of up to 50 kW, and

(b) dynamic charging of 50 kW and above.

Key benefits include the possibility of downsizing battery packs, which could make this technology suitable for inter-city electric buses and potentially serve as an alternative to light rail or metro systems. However, India currently lacks established standards and proof-of-concept deployments for inductive charging, making implementation complex. High capital and operational costs, grid strain due to substantial power requirements, and unresolved technical challenges remain significant barriers.

Pantograph Down Charging

Pantograph technology, long established in railway systems, is increasingly being adapted for EV charging globally, particularly for depot and opportunity charging applications. Capable of delivering up to 600 kW, pantograph systems substantially reduce charging times. Pantograph solutions in India offer safe and reliable automated connections at voltage levels ranging from 150 V to 850 V and power levels of 100 kW, 150 kW, 300 kW, 450 kW, and 600 kW. Connector-based charging systems typically support around 10,000 cycles, whereas pantograph charging systems can support up to 30,000 cycles.

In addition to electric bus charging, pantographs can be deployed in mining and drayage applications, where heavy-duty vehicles have limited time available for charging. One of the key advantages of pantograph charging is that it reduces the need for large, expensive onboard battery packs.

However, transitioning from cable-based systems to pantograph technology requires installing compatible bus bars or rails on e-buses, additional components for wireless communication, and modifications to junction boxes. This technology holds significant potential for addressing the charging requirements of HDVs and large vans of varying sizes and capacities using common charging infrastructure. Interoperability is a key consideration.

Pantograph systems demand up to 450 kW per bus, creating grid stability concerns when multiple vehicles charge simultaneously. Solutions such as Battery Energy Storage Systems (BESS), Vehicle-to-Grid (V2G) integration, and innovative business models like Battery-as-a-Service (BaaS) can help mitigate these challenges. Pantograph charging offers interoperability, long infrastructure life, and operational efficiency—positioning India to meet its clean mobility goals effectively.

Megawatt-Hour Charging

Megawatt-hour charging delivers up to 3.75 MW of peak power through a single connector, enabling ultra-fast charging for heavy-duty vehicles such as trucks and buses at voltages of up to 1,250 V and currents of up to 3,000 A. The lack of Indian standards for Megawatt Charging Systems (MCS) complicates regulatory compliance, and significant grid capacity assessments and charge management readiness evaluations are required.

The long-term impact of such high-power charging on battery life also needs careful evaluation. Ensuring modular system design, robust communication during high-power charging, effective heat dissipation, and adherence to safety standards is critical. The high-voltage architecture must be capable of handling extreme currents, electromagnetic interference (EMI), and increased mechanical and thermal stresses.

Establishing MCS stations at logistics hubs and ports requires substantial grid capacity and advanced energy management. Charge scheduling and predictive planning will be necessary to optimize station utilization and meet commercial vehicle demand. Comprehensive feasibility assessments from both grid readiness and EV readiness perspectives are essential.

Battery Swapping

Battery swapping is an alternative to fixed-battery charging systems, involving the replacement of discharged batteries with fully charged ones. For e-HDVs, battery replacement is performed robotically, unlike the manual swapping used for 2Ws and 3Ws. This approach separates battery ownership and charging from vehicle operation, keeping vehicles on the road with minimal downtime. Battery swapping is comparable to refuelling internal combustion engine vehicles and typically takes 1–3 minutes.

This technology falls under the broader umbrella of Battery-as-a-Service (BaaS), where users purchase EVs without batteries, which typically account for 40–50% of the total vehicle cost. Users access batteries through subscription-based services offered by OEMs or third-party BaaS providers.

Battery swapping remains nascent in India but is gaining traction, particularly in commercial and fleet operations. In September 2025, the Nhava Sheva Distribution Terminal at the Jawaharlal Nehru Port Authority deployed 50 swappable-battery trucks. OEMs such as Ashok Leyland, Energy in Motion, Sun Mobility, and Blue Energy are actively engaged in advancing this technology.

Looking Ahead

This article provides an overview of emerging charging technologies for heavy-duty vehicles, specifically e-buses and e-trucks. Each technology presents distinct advantages, limitations, and challenges, and several require further real-world validation. Controlled field trials, feasibility studies, and the development of India-specific standards are essential to assess performance under tropical climatic conditions.

It is also imperative to evaluate grid impacts and ensure effective integration of renewable energy sources to mitigate grid imbalance while meeting the charging requirements of heavy-duty vehicles. Collaboration among policymakers, industry stakeholders, utilities, and research institutions will be critical for the successful implementation of these technologies.

Suresh Babu Muttana is Scientist E, CEST Division, Department of Science and Technology (DST), Government of India; Sharif Qamar is Associate Director at The Energy and Resources Institute (TERI), New Delhi; and Dr. Anita Gupta is Scientist G & Head, CEST Division, DST. Views expressed are the authors’ personal.