Before I get into why—and how Campbell and Elkins plan to make Gore a big player in digital health—a little background.

Gore uses PTFE—a.k.a. Teflon—in all sorts of form factors for a variety of products—as computer ribbon cables (dating back to the IBM 360), as other electronic cables, as filtration membranes, as EMI shielding in mobile devices, as cardiovascular grafts and stents, and, of course, as Gore-Tex.

While its initial products used standard PTFE, today all of its products are made with so-called expanded PTFE (ePTFE), a form of stretched PTFE discovered accidentally by company founder Bob Gore in 1969. And it’s this expanded PTFE that Campbell and Elkins think could make the difference for digital health wearables.

Expanded PTFE is weird stuff. When heated, a typical fluoropolymer will break if stretched quickly, and elongate when stretched slowly. Indeed, when PTFE is stretched slowly, the material behaves as you would expect it to—it elongates, thins, and eventually breaks.

But when PTFE is stretched quickly, it elongates but keeps its original shape. Instead of thinning out, a structure of nodes and fibers surrounding voids forms throughout, and the material—now expanded PTFE—is extremely flexible. This web can be filled in with other materials (nickel, for example, is added for use as shielding), or left air-filled for flexibility, as in the company’s vascular grafts.

For wearables, expanded PTFE has a number of features that make it an ideal material, says Elkins. For one, it can allow air or even water vapor through while still being waterproof—handy for sweaty athletes concerned with wearable structure.

And the surface properties of the material can be changed locally. For example, one sheet of material can be structured to be both waterproof and breathable, making it comfortable for long-term wear but also able to protect electronic components from moisture.

Another attractive feature is that manufacturers can print electronic circuits directly onto it, she says. And lab tests indicate that the material can be used to create electronic components that maintain a constant resistance when being stretched, she pointed out, though that feature has yet to make it into a product.

Gore executives concluded that the company wasn’t going to be able to quickly turn the material into digital health products itself. Instead, the company needed to tap into the startup community. In 2017, Gore launched what it informally calls the Gore Patch Project—taking startups with, says Campbell, “great sensors and algorithms and cloud connectivity and helping them with wearability, helping them solve their materials science challenges, like waterproofing, skin interaction, sweat, and comfort.”

“We think,” said Campbell, “that we can help change these products from something like the classic pink rubber eraser—thick and only slightly flexible—to something more like a Band-Aid.”

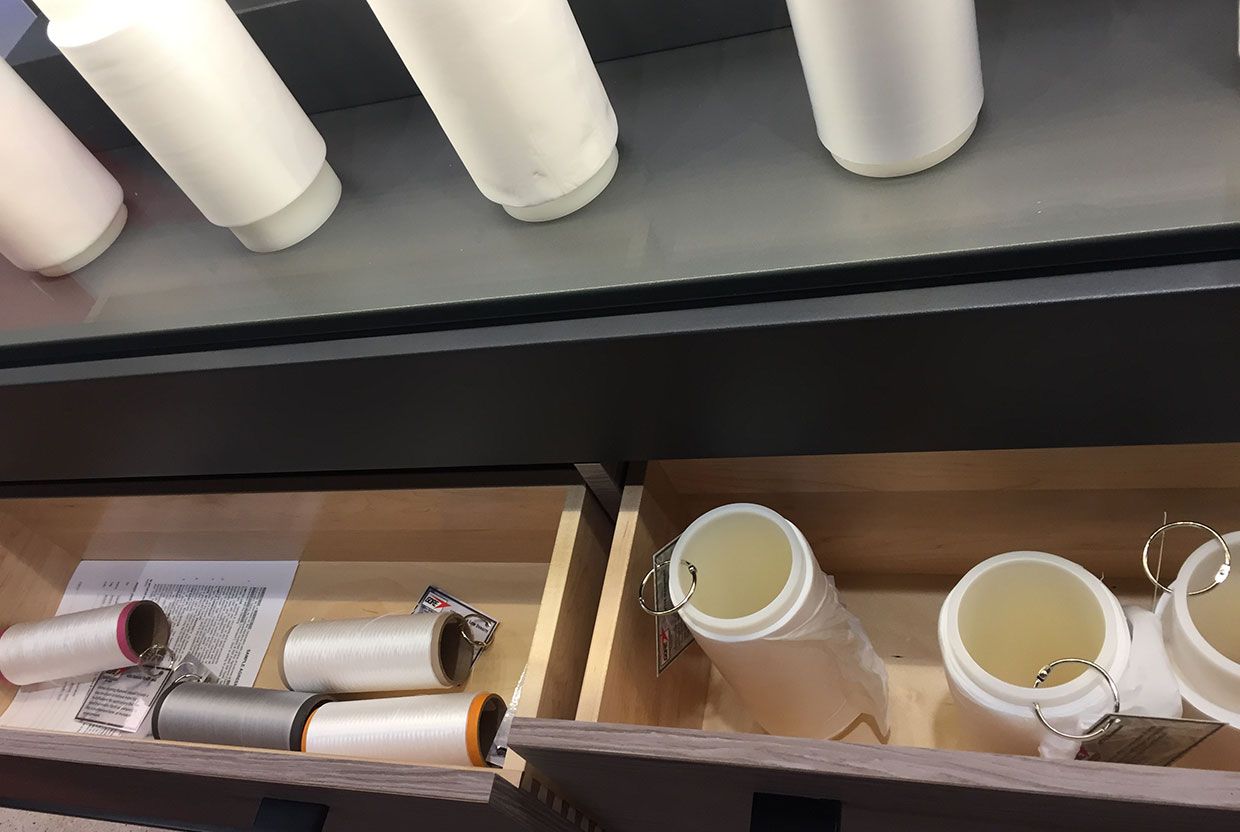

Wanting to tap into the Silicon Valley startup community in particular (though it’s looking for startups around the world), Gore late last year cut the ribbon on an 11,000-square foot innovation center: space for these potential patch-makers to work on their products. The center has all sorts of shiny new equipment waiting to be used—traditional laboratory equipment, general prototyping equipment, and tables stocked with a wide variety of Gore-made ePTFE-based materials, along with art and design tools and other maker gear. It also has conference spaces and co-working areas. The plan is to fill this space with a rotating group of startups. The startups will get help from Gore scientists and engineers, initially on short assignments from other locations, though some are expected to relocate permanently.

Campbell and Elkins have met with about 500 startups over the past year, and signed three on to the innovation program so far, offering them a combination of equity investment and joint development agreements. The structure of these packages is flexible, other companies may come on board with research grants or other types of partnerships. Only two of the deals have been made public to date:

-

Bonbouton: developing printable graphene-based temperature sensors. An extremely thin, flexible, temperature sensor would be particularly useful for monitoring the condition of the feet in people with diabetes, for example.

-

Kenzen: field testing a sensor patch that looks at biomarkers in sweat to monitor the health of workers in extreme environments, such as mines, and alerts the workers and safety monitors to potential problems.

And the innovation center expects to have a fourth startup coming on board in a few months—the winner of the MedTech Innovator Competition. It’s still early days, but other plans for the facility include hosting hackathons, innovation forums, and startup pitch days. Startups are also brought in informally (Campbell and Elkins are networking like crazy), shown materials, and sometimes given samples to work with.

Campbell and Elkins expect to eventually have some kind of partnership agreement with 20 startups. They aren’t releasing a timeline, but expect to move quickly. After that, they will add new partners to keep the field to about that number as companies move out of the development phase. Campbell, who previously incubated startups at Hewlett-Packard and Philips, says, “In my experience, 20 is a magic number, the number we can manage with a small team, without layers of management.”

If you think your company should be one of those 20, you can contact the Gore Innovation Center directly.