In recent years, the “smart factory“concept that arose from Industry 4.0 and Industrial Internet of Things (IIoT) topics has become an increasingly popular term. Smart factories, via IIoT-enabling technologies, have the potential to improve productivity, reduce waste and downtime, and optimize manufacturing processes.

[Native Advertisement]

Machine vision has a key role to play in the smart factory of the future, as well, where automated manufacturing lines will be able to self-adjust to maximize quality, output, and profitability. Smart factories are no longer a pipe dream concept, but one that is here—offering those in manufacturing, logistics, and warehousing environments the chance to improve overall processes. During a free webcast on February 27, Tom Brennan, President, Artemis Vision, will discuss smart factory concepts and the role that machine vision must play.

Additionally, he will discuss the enabling technologies, various benefits, and considerations one must make to maximize the potential benefits that a smart factory offers.

Webcast information:

Industry 4.0: Machine vision’s role in the smart factory

Tom Brennan, President, Artemis Vision

February 27, 2019, 11:00 AM EST

You may also like:

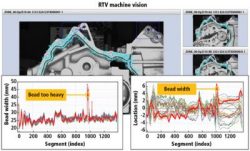

Machine vision data management software simplifies root-cause analysis: Cross-process analysis of machine vision images, image data and other process data improves quality, process control, and enables continuous process improvements

“OPC Vision” release candidate presented: In the future, the two worlds of image processing and industrial automation will interlock seamlessly and in real time without the use of proprietary interfaces. This is the result of the “OPC UA Companion Specification for Machine Vision.”

: The 2019 Automation Market Update delivered at the A3 Business Forum by Alex Shikany, Vice President of the AIA, gave a snapshot of the robotics, vision, and motion control markets.