3 H BY MARK KANE

Volkswagen has already decided where to buy the lightest metal

Volkswagen Group announced a new memorandum of understanding for long-term lithium supplies for battery cells with Ganfeng Lithium Co., Ltd. registered in Jiangxi (China).

The agreement covers supply of lithium to VW and battery manufacturer selected by VW over the next 10 years.

The German manufacturer said that this way it’s already securing a significant share of its lithium requirement. By the way, talks with Ganfeng Lithium concerns other topics like battery recycling and solid-state batteries too.

“The rapid increase in vehicle electrification in the automotive industry will have a major impact on global raw material markets. The global lithium demand is expected to more than double by 2023. In light of this, the agreement with Ganfeng is an important milestone in supply security for the Volkswagen Group.”

Volkswagen is not the only carmaker that needs to secure raw materials in very high volume at affordable prices for its own suppliers of battery cells. A similar deal was announced between Tesla and Ganfeng Lithium several months ago.

Dr. Stefan Sommer, Group Board Member for Components and Procurement at Volkswagen Aktiengesellschaft, said:

“Over the next ten years the Volkswagen Group will be launching 70-plus new pure electric vehicles. That means approximately a quarter of the vehicles we deliver in 2025 will be powered by electricity. Consequently, there will be a rapid increase in our raw material demand for cell production in the coming years. We must make sure we cover this demand at an early stage. Long-term agreements like the one for lithium, a key raw material, that we have just concluded with Ganfeng are therefore of crucial strategic significance for implementing our electric offensive.”

Michael Bäcker, Head of Corporate Purchasing e-Mobility at Volkswagen Aktiengesellschaft, explained:

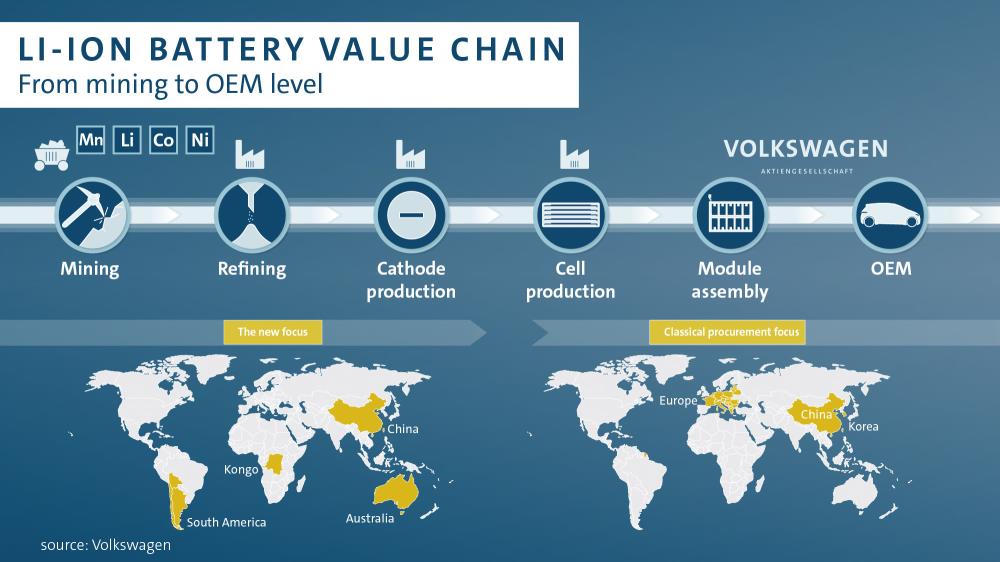

“With Ganfeng as a strategic partner we are creating a secure basis for planning capacities and costs. The strategic collaboration is the result of an extensive market analysis executed by Volkswagen’s e-Raw Material Team. This specialized team is focusing on building close relationships with the raw material industry. Together with selected strategic partners, Volkswagen is identifying and establishing common synergies along the HV-battery value chain. During this process we consider a sustainable value chain as equally important to securing material capacities and competitive pricing structures.”

The higher energy cells like NCM 811 or NCA usually are produced using lithium-hydroxide:

Categories: Battery Tech, China, Volkswagen