by Mayank Dhingra & Nikhil Bhatia Feb 13, 2018

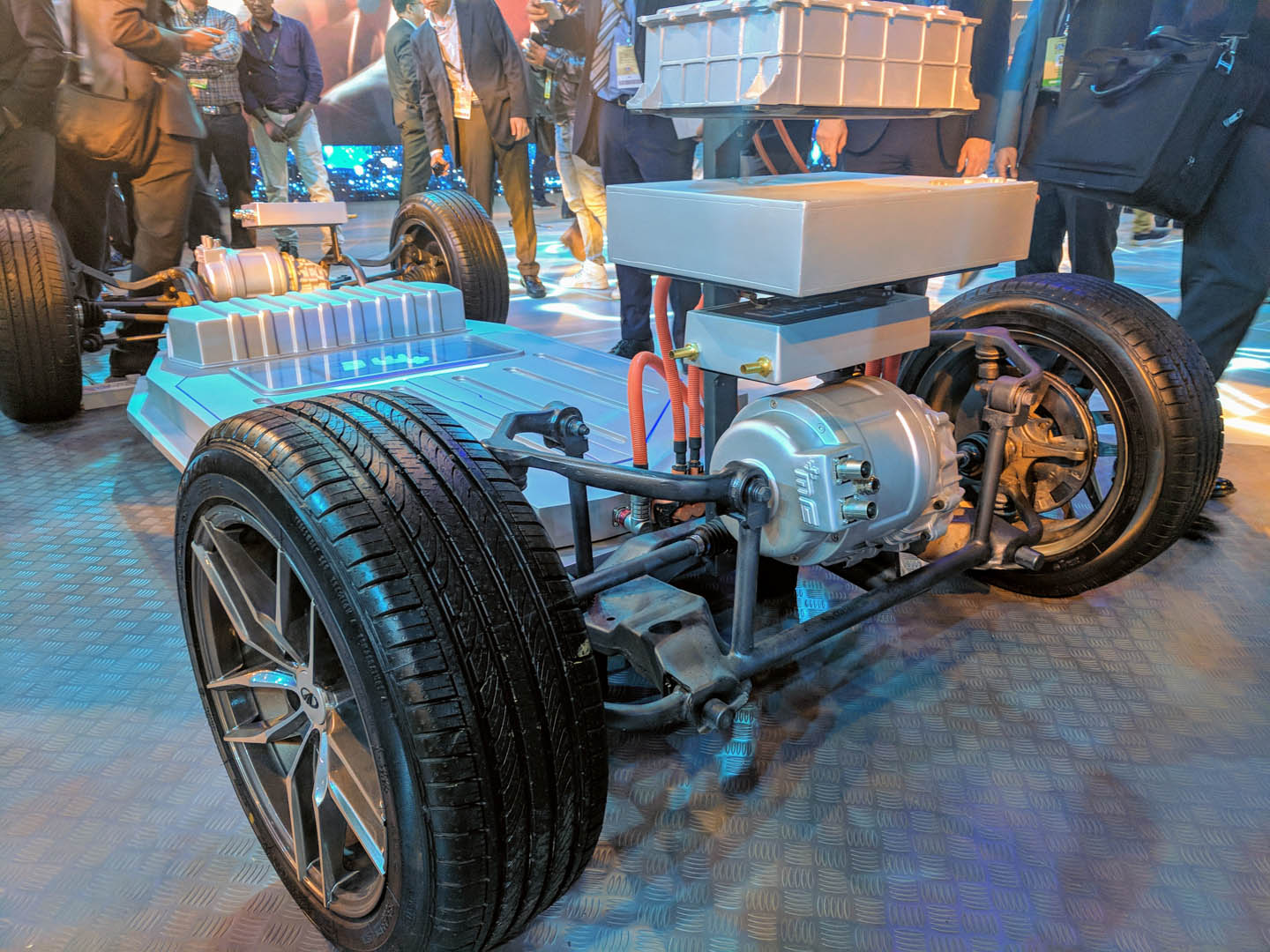

Designed completely from the ground up, the Mahindra Electric Scalable Modular Architecture (MESMA) platform was one of the key highlights from the stables of Mahindra & Mahindra at 2018 Auto Expo.

The company, which could be attributed to have pioneered the e-mobility drive in the country, gave a hint of the ongoing developments inside its research centre in Bangalore, which brought the EV platform to life.

The all-new modular architecture boasts a low-set Lithium-Ion battery pack into the floor, which aids in getting a low centre of gravity, along with liberating maximum cabin room with a fully flat floor. The platform can support multi-motor configurations with a single 50kW motor at the rear, or a combination of two motors, one each at the front and back, thus, catering to a diverse range of vehicle segments. The company is also looking to integrate the motor control unit as well as the power electronics inside the system so as to enhance the compactness of the whole architecture.

Mahindra Electric is planning to underpin a whole new range of models on the MESMA platform, the first one of which is set to be out within the next three years. According to Steeven Woolley, CTO, Mahindra Electric, “After introducing the first product, we would be bringing out a new offering, based on MESMA every 12 months, utilising the flexibility of the new platform.”

“The design of the battery module enables us to go from a 21kWh to 304kWh battery pack, which translates to an effective range between 240km to over 390km on a single charge. The wheelbase could also be extended by up to 300mm and the extra under-seat storage could then be leveraged to further enhance the battery capacity from 34kWh to 54kWh and shoot the range to up to 590km as per the New European Driving Cycle (NEDC) tests,” he added.

While the MESMA is good to spawn compact crossovers, more in lines of the Mahindra KUV100 in size and heft, Mahindra Electric will eventually develop a MESMA-2 platform, which will see mid-size and full-sized SUVs being formulated using a dual-motor setup for more power and torque. The multi-motor layout will also help in choosing from a variety of drivetrain options, including concentric gearboxes which offer better efficiency.

For small and medium cars though, Mahindra Electric will consider putting a single motor driving the rear wheels, in order to get smaller turning radius with such a setup, which is a crucial feature to have for city driving.

Future technological breakthroughsWhile car manufacturers go on and unveil concepts with motors at individual wheels, as per Woolley, such a setup requires bigger wheel diameters. “An SUV is an ideal opportunity to put in individual motors at each wheel. We will look for four-wheel-drive setups with such layouts and with regard smaller cars, while hub motors have been in development since a long time now, but, there still remains a challenge to incorporate the brakes along with the motors. Tremendous work is being done to resolve this packaging constraint and the next two to five years will see a lot of new technology being coming out,” said Woolley.

“On the battery front, technologies like lithium-air are going to emerge as evolutions to lithium-ion. Like most companies, we are also looking at alternative battery technologies, where Li-ion is going to power the industry in the short term until 2025. Beyond that, we would have to look at solid state battery technologies, wherein by 2030, Lithium-air has the potential to be a game changer as it has better energy density than Li-ion.”

Where at cell level, most batteries produce around 230 to 250Wh/kg, Li-air, on the other hand, would give between 1,500 to 2,000Wh/kg. “So, it’s a very different game altogether but the concern is that it is very power-dense and needs very big battery size to bring out all that energy. It is still some time away and is one that I really hope that is able to come in and change the entire EV industry,” concluded Woolley.