“

Marchant Cain is a company born out of a desire to solve problems that others can’t. We visited their new factory in Coventry to find out more.

“It is crazy,” Pam Cain, director at Marchant Cain tells me. “We will have done the same turnover in less than six months this year, than we did for the whole of last year.”

Last month, the company officially opened the doors to its new factory at Banner Park in Coventry, three times the size of the previous one.

Marchant Cain designs, develops and manufactures parts for luxury car brands including Aston Martin, Porsche and Bentley, and is currently working on a whole host of contracts for customers across the world.

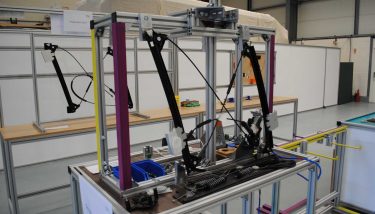

“This is the production hall, but we still have a lot of prototyping going on as we’re gearing up for production to start,” Pam says, as we walk around the new site.

Order overflow

As usual, the team has many, many plans in the pipeline. “I can’t tell you, there is just so much going on at the moment,” she says. “With the way things are moving, we might not even have enough room here for production.”

Marchant Cain is as in demand as ever, developing and working on a diverse range of innovative projects, from aerodynamic components for supercars to developing a 3D print farm, to utilising its expertise in cable technologies.

One of the most exciting projects the engineering firm is working on is developing acoustic barriers for railways. “We are in discussions with HS2, as they believe we are the only people who understand how to solve the problems they have. If that happens in the way we think it might, we will have to set up a new company and a new factory. It is exciting,” Pam says.

From Vietnam to Porsche

Founded in 2006 by duo Pam Cain and Rob Marchant, the firm worked on various innovative projects until it got its big break five years later. This saw them develop a car that could be driven with the doors open and the roof down in Vietnam.

The firm was then recommended to Porsche to develop a component for the 918 Spyder model. The automotive manufacturer was impressed with the company’s prototyping and hired Marchant Cain to make 2,000 actuators for 1,000 cars.

The company’s growth remains on a steep trajectory and when speaking to Pam or Rob, their expertise of industry and how to be innovative is crystal clear.

Marchant Cain is also well-known for using its knowledge of cable technologies to design and make window regulators – the mechanism that enables glass to fit and move in niche, highly-specialised cars.

It might sound simple, but the team must understand the exact movements the glass will take. For hypercars that look more like a piece of art than a car, this is a task which requires precision accuracy.

A windowless future

Marchant Cain is always one step ahead. Pam shows me flexible hinging, something that uses the team’s understanding of cable technologies to allow the front splitter of a car to be more flexible, something (like many of their projects) that has never been done before.

“We mocked this up to demonstrate our advanced understanding of cable technologies that we use in window regulators.

“We are transferring that into other products because we recognise that one day, cars won’t necessarily have windows, so they won’t need window regulators. We need to be thinking ahead all the time about what we are going to be doing next,” said Pam.