Will we ever see such a tool working to create entire car frames?

After the presentation of the Model 3, it seems the Model Y did not get that much love from the audience. But it surely got it from Tesla. The compact SUV may be the first Tesla product to have not only a revolutionary wiring system, but it will possibly premiere another innovation: a giant casting machine for its frame.

Again, Tesla is tired of manufacturing processes that make companies lose a lot of time and money. This is the main reason it has created the new wiring system, which we have already told you about. And this is the main argument in favor of the new casting machine.

A normal unibody car frame consists of dozens of small and large metal parts. They are folded and cut by giant dies in stamping machines, and then are glued or welded together by people or robots. It is like a giant origami. Tesla’s patented casting machine plans to end the “folding” and gluing part of the process.

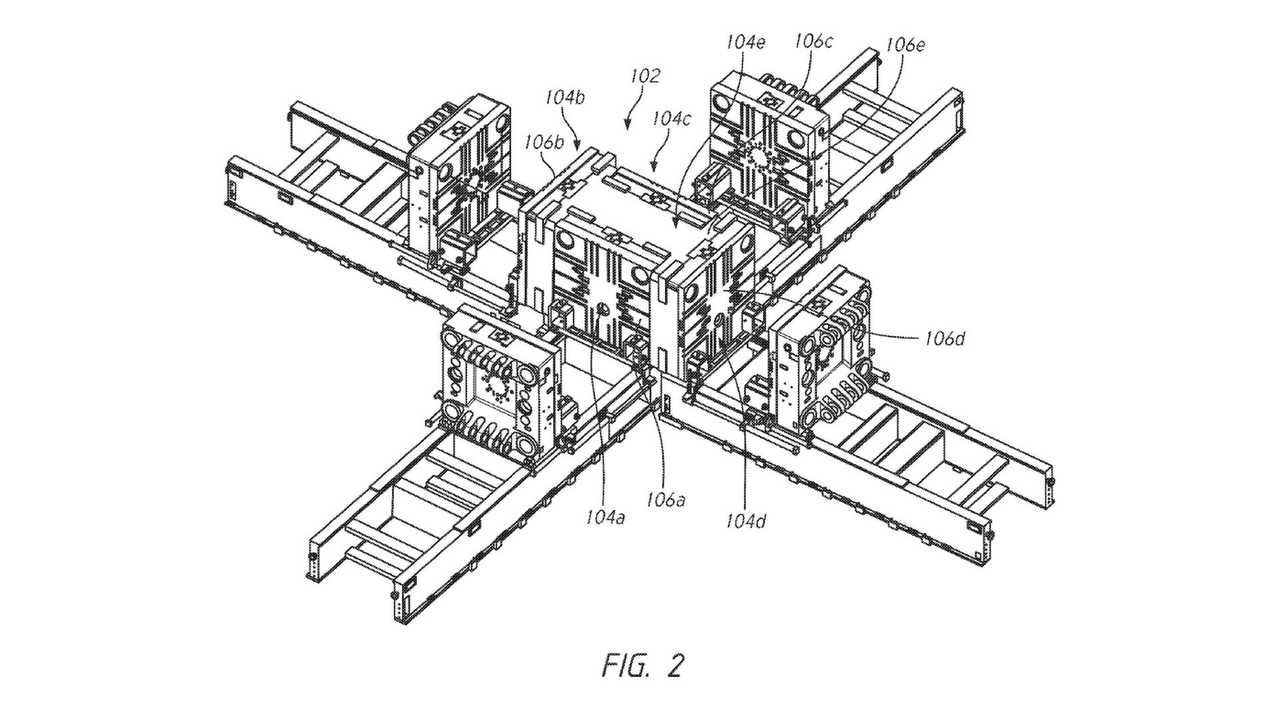

The American EV manufacturer calls the new tool a “multi-directional unibody casting machine for a vehicle frame.” So it obviously has to do with the structure of future Tesla vehicles. The company says it may use “hot or cold chamber die casting machine.”

Elektrek, which has also disclosed the new patent application, remembers Elon Musk said last June Tesla would move into aluminum casting for the structure of vehicles. Musk even said that when his company got “the big casting machine” – now we know what he meant – it would go “from 70 parts to 1.”

The big casting machine may be a hell of an investment, but it can save a lot in terms of fewer robots of people involved in welding or gluing the metal together. Aluminum would possibly also make the cars lighter, depending on the thickness of the structure the machine is able to create.

We’ll let you have a look at the patent application for the juicy details and also to try to answer the following question: will such a solution make repairing these cars more expensive?

It may be troublesome to put 70 pieces together, but it is also more practical to extract a few damaged parts and welding new ones than replacing a whole structure.

This is something we are curious to see on the future Tesla models. And probably as a first in the Model Y. We believe the company will create auxiliary crash boxes in order to preserve the car’s frame. If an accident damages it, that will probably be a case of a total loss.