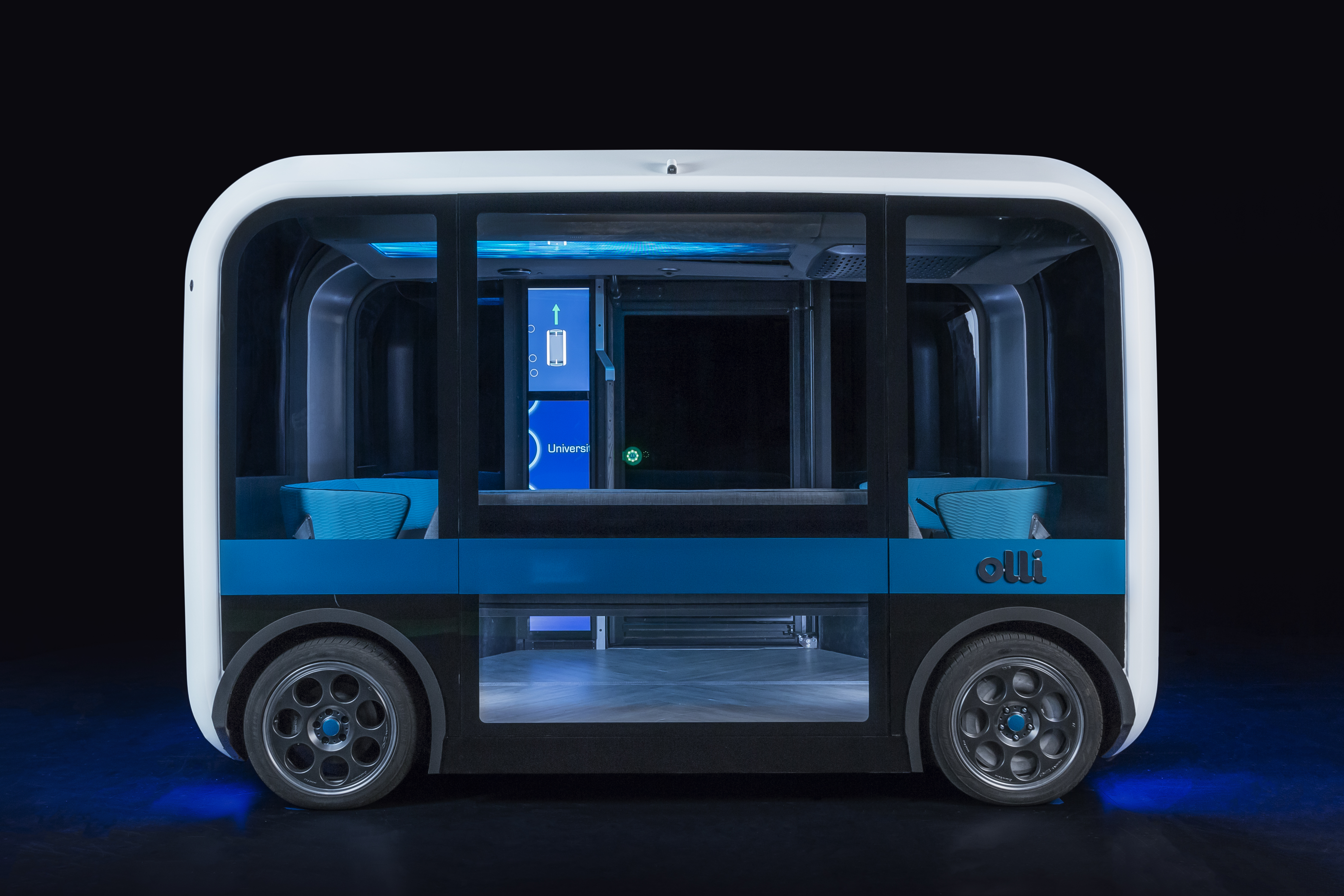

Local Motors, an Arizona-based automotive OEM, has introduced an upgrade of its 3D printed, electric, autonomous shuttle known as the Olli 2.0.

The Olli 2.0 is designed for neighborhoods, campuses, and urban city centers as a smart, safe, sustainable transportation option. As opposed to its predecessor, Olli, Olli 2.0 uses 50% reduced parts and decreases manual production hours by 50%.

“The future is here; it’s just not evenly distributed,” explained John B. Rogers, Jr, co-founder and CEO of Local Motors. “That’s something I say a lot. Because people often ask me, ‘Hey, when will I see this vehicle? 2023? What do you think?’ My response: It’s here now, it’s just not everywhere.”

A 3D printed, self-driving shuttle

Olli was first presented in 2016 as a low speed, on-demand, self-driving shuttle capable of transporting 12 passengers. Enabled by additive manufacturing, more specifically, a Big Area Additive Manufacturing (BAAM) 3D printer from Cincinnati Incorporated BAAM printer, and an IBM Watson IoT platform, this vehicle can be 3D printed and assembled in under 10 hours.

Moreover, Olli is equipped with 360° LiDAR scanners which can sense the surroundings in all directions. As a result of 3D printing, the vehicle can be customised for different environments and needs. Numerous road tests, including Olli on the streets of Berlin in a collaboration with Deutsche Bahn, has led to the 3D printed shuttle’s recent deployment at the Sacramento State University campus.

According to Local Motors, Olli 2.0 has been developed with more options including natural language recognition which can be altered to make the system addressable to “Olli.”

The Olli 2.0

As well as voice recognition, Olli 2.0 integrates a cognition from MIT start-up Affectiva which enables facial and mood tracking of its passengers and dynamic route optimisation. In addition, it can reach a maximum speed of 25 MPH, offering optimal safety.

Phasing out its previous model, Olli 2.0 is currently in production at Local Motors Industries’ microfactory in Knoxville, Tennessee, and will be deployed in the coming months.

For regular additive manufacturing news updates subscribe to our 3D Printing Industry Newsletter, follow us on Twitter and like us on Facebook. Visit 3D Printing Jobs for new additive manufacturing opportunities in your area.