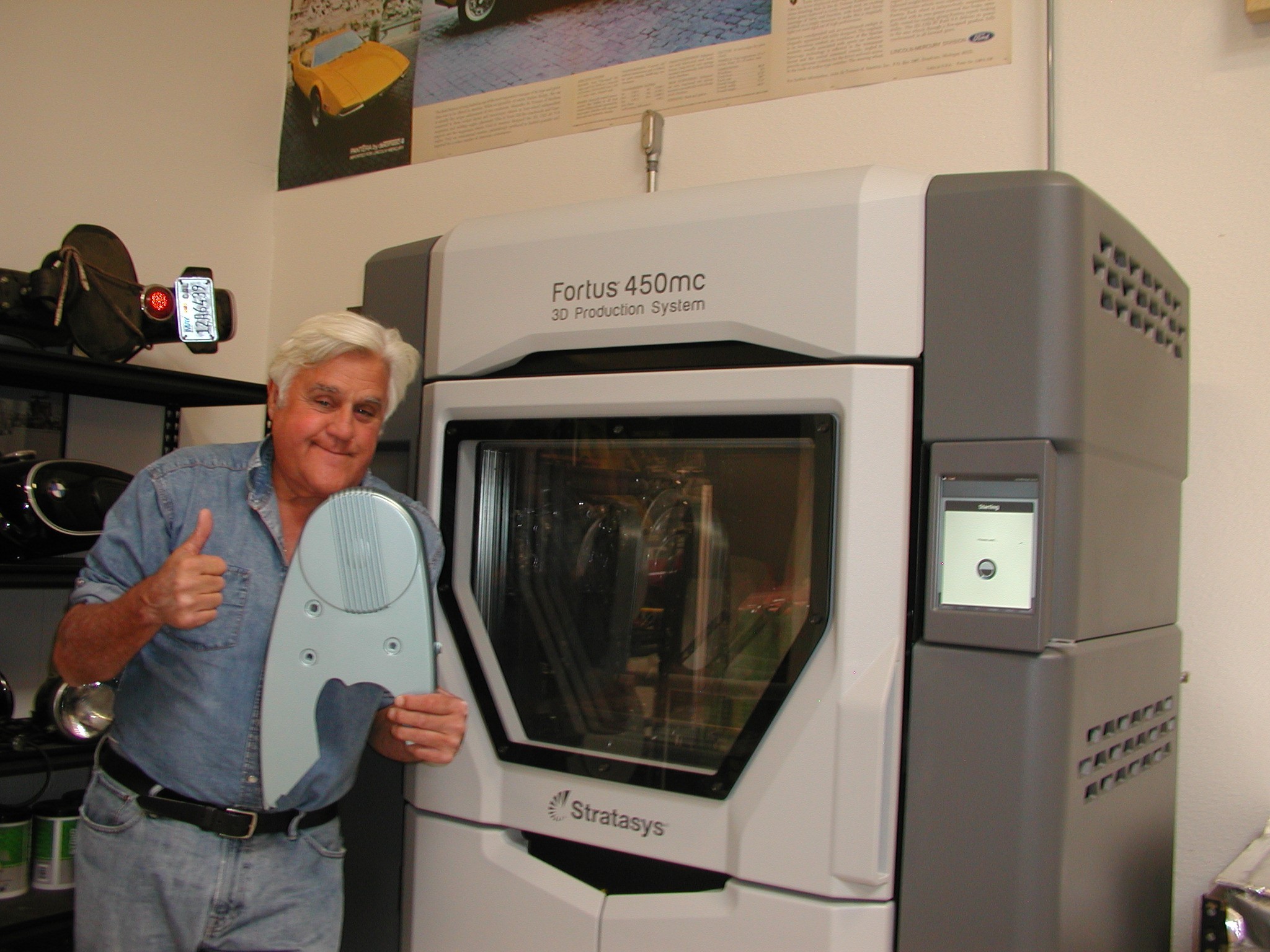

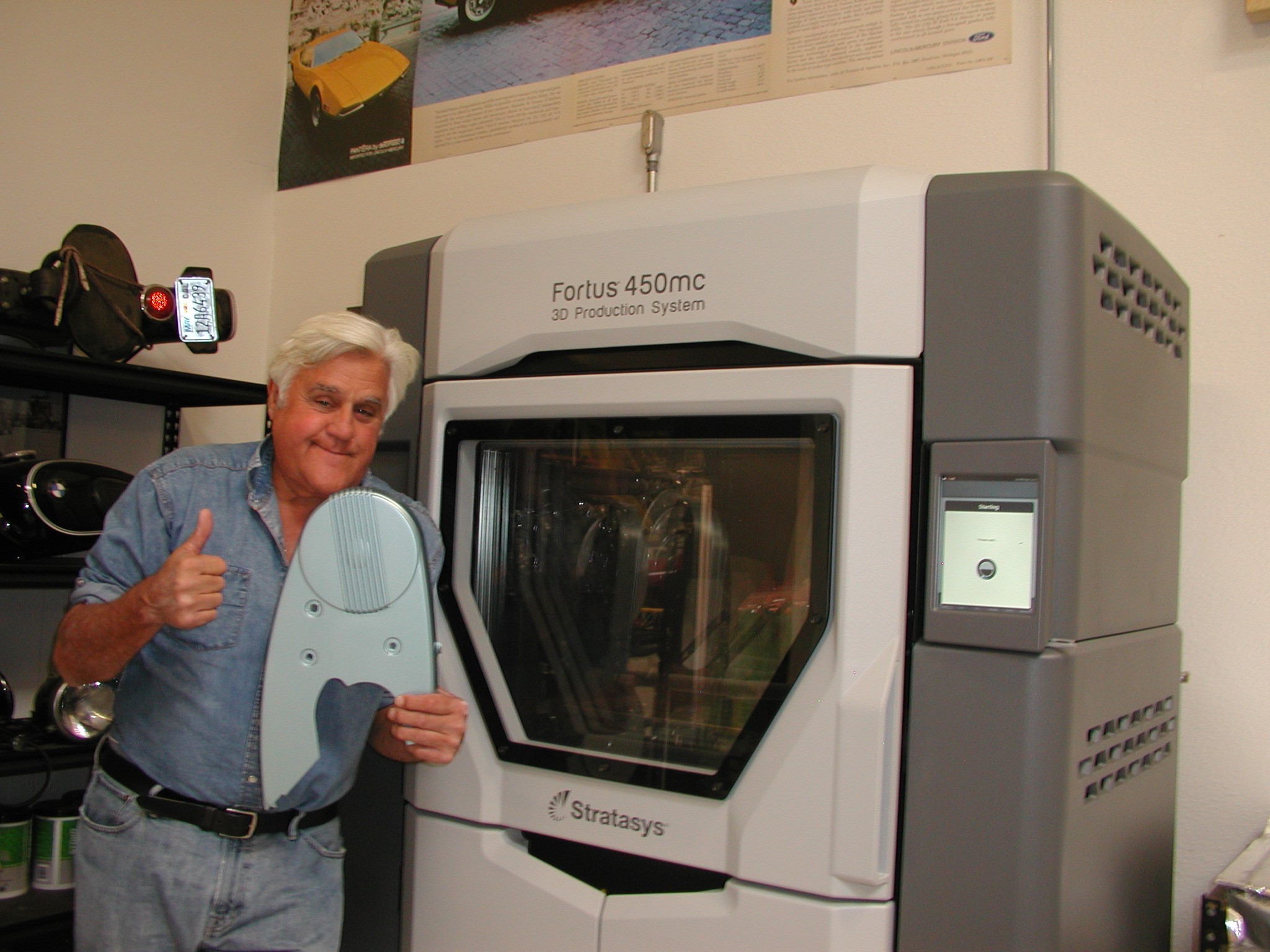

Stratasys has announced it is collaborating with Big Dog Productions, the media production firm headed by North American comedian Jay Leno. The new partnership is an extension of Stratasys’ Performance Partner Program.

As part of the program, Stratasys will be providing the company with access to its FDM 3D printers to support the motor vehicle television series “Jay Leno’s Garage”, in which the former “Tonight Show” host conducts reviews on a wide range of vehicles, including vintage and restored cars. With access to Stratasys 3D printers, Leno intends to service his large collection of vehicles, located at his Big Dog Garage in Burbank, California, with 3D printed custom parts.

“Jay has long been one of the pioneers and adopters of 3D printing. He realized the technology’s potential for on-demand, custom parts early on – claiming it as a critical component to fueling a passion for classic vehicles,” commented Pat Carey, Senior Vice President of Strategic Growth Americas at Stratasys.

“We cannot wait to see what uses of 3D printing they come up with next, because if they can dream it, we can 3D print it.”

Performance Partner Program

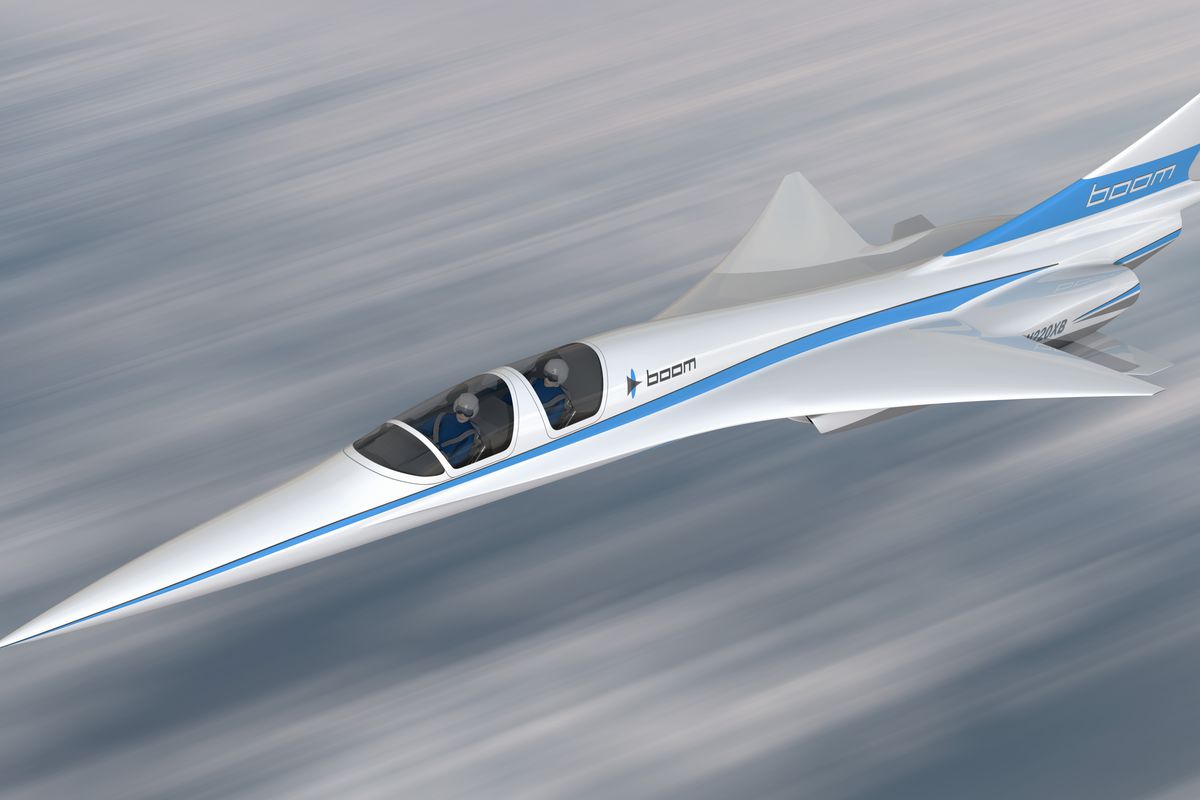

The Performance Partner Program from Stratasys was announced recently, in September 2019, and it aims to connect auto racing, competitive sailing and supersonic travel teams leveraging additive manufacturing. “Never before has there been a focused, collaborative group of the who’s who of these industries – dedicated to advancing the use of additive manufacturing across these high-performance environments,” explained Pat Carey, Senior Vice President of Strategic Growth at Stratasys.

At launch, the Performance Partner Program consisted of 11 partners. This includes Colorado-based aerospace company Boom Supersonic, which recently extended its partnership with Stratasys to further accelerate the adoption of additive manufacturing for flight hardware. NTT IndyCar Series racing team Arrow Schmidt Peterson Motorsports (Arrow SPM) is also a part of the program. The racing team has integrated the Fortus 450mc and F370 3D printers from Stratasys to accelerate design iterations, workflows, and final part production.

Harnessing 3D printing for automotive digital inventory

As an extension of Stratasys’ Performance Partner Program, Jay Leno’s Garage/Big Dog Productions will leverage 3D printing to build a digital inventory that helps road test, refurbish and retrofit classic vehicles and supercars in Leno’s collection. Located within the Big Dog Garage are 169 cars and 117 motorcycles. Previously, Big Dog had already been collaborating with Stratasys Direct, the company’s on-demand manufacturing service, for nearly 10 years.

Jay Leno and Big Dog Garage will henceforth have access to core Stratasys additive manufacturing solutions, which includes the Fortus 450mc 3D printer and FDM Nylon 12 Carbon Fiber. Thus far, Leno has worked with the extended Stratasys team to produce high performing 3D printed prototypes and custom parts for the automotive collection. The technology has provided a significant advantage in facilitating the re-creation of parts no longer on the market or components that would prove too time-consuming to manufacture using traditional methods.

“As a lover of classic cars, I’m always looking to push the boundaries of what’s possible in creation and re-creation of these vehicles – and 3D printing is integral to this process,” explained Jay Leno. “After working with Stratasys and Stratasys Direct for years to drive the ultimate in 3D printing innovation, I’m really excited about this new Fortus machine and where it takes us next.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Jay Leno’s Garage. Photo via Walker Dalton/CNBC.