From 2023 on, Volkswagen intends to produce 1.4 million of similar electric drive units annually.

Volkswagen recently showed an electric motor, the first in a family, compact enough to fit in a sports bag, despite delivering more than 200 horsepower. That’s the beauty of an electric drive.

” It’s not only less complex than a conventional petrol or diesel engine, but also compact enough to fit in a sports bag.”

This particular drive unit, produced by Volkswagen Group Components, is called the APP 310 electric drive and will be used in the all-new Volkswagen ID.3 model.

Volkswagen explains that “the designation “APP” derives from the arrangement of the drive and the gearbox in parallel with the axle”, while 310 is torque value.

APP 310 electric drive for modular electric drive matrix (MEB):

- single-speed

- 150 kW (200 PS) of peak power

- 310 Nm of peak torque

- a permanent magnet brushless machine

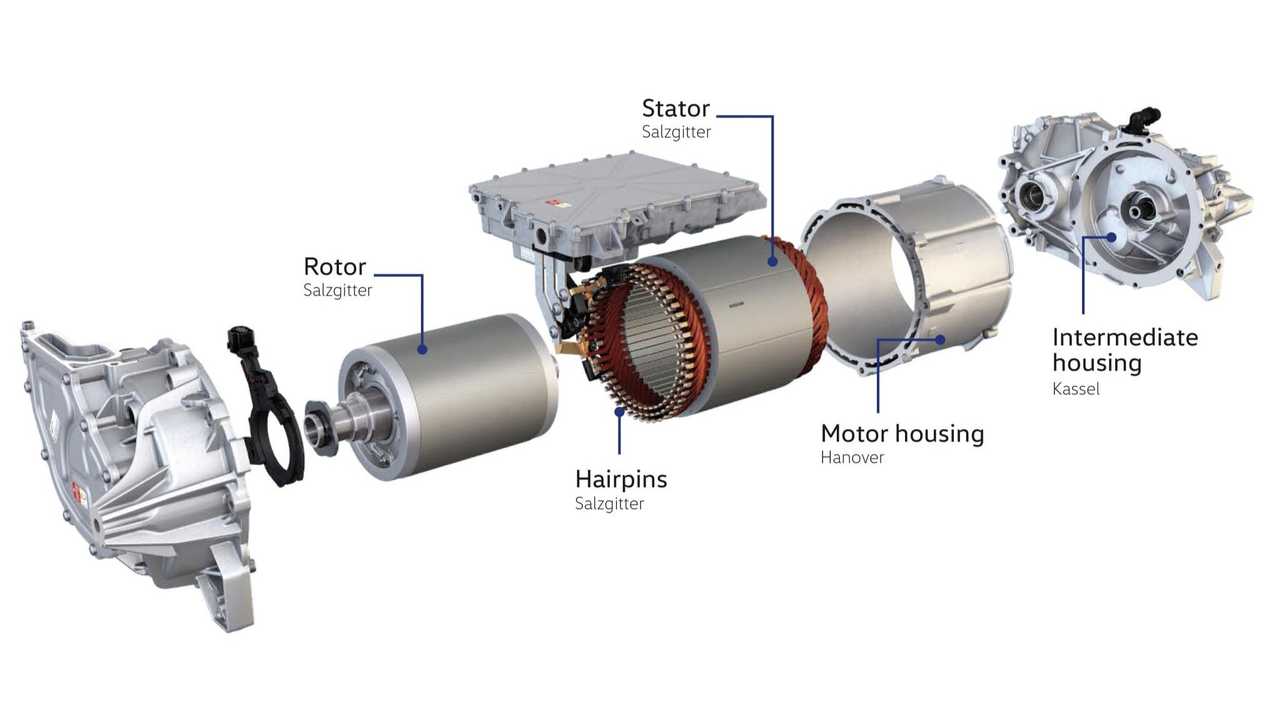

Volkswagen Group Components produce these drive units in Kassel, Germany, but actually particular parts come from a few facilities:

More about the drive units:

Components of an electric drive

Inside every electric motor is a stationary stator with a rotor spinning inside it. The stator is made of copper wire coils. When an electric current flows through these coils, a rotating magnetic field is created in the stator which causes the rotor to spin. The rotational movement is based on a simple physical principle: opposite poles in a magnet attract each other, whereas like poles repel. Furthermore, there are two types of electric drive: permanent magnet brushless machines and asynchronous machines. The permanent magnet brushless machine features a strong permanent magnet rotor, which rotates in sync with the magnetic field of the stator. In asynchronous machines, however, the rotor uses the electric current to generate its own magnetic field and, as a result, the rotation of the rotor lags behind the stator’s magnetic field rotation.Hairpin technology and consistent lightweight construction

Volkswagen’s new ID.3 is fitted with an APP 310 electric drive. This drive is a permanent magnet brushless machine. The designation “APP” derives from the arrangement of the drive and the gearbox in parallel with the axle, whilst the numerical sequence that follows derives from the maximum torque of 310 Nm. The main components for this drive are produced using a combination of specialisation and Group manufacturing at various Volkswagen Group Components production sites.The rotor and stator are produced at the component plant in Salzgitter. New hairpin technology has enabled the use of an innovative production process for the assembly of the stator, whereby the spaces within the laminated core of the stator are optimally filled with flat preformed copper coils. This increases the torque density and the efficiency of the electric drive in comparison to that of a drive with wound copper wire coils. Maximum torque is achieved even at a low engine speed, which means that a 1-speed gearbox is sufficient for the entire rotational speed range. Both the electric drive and the 1-speed gearbox are produced at the component plant in Kassel. The whole drive unit, together with the 1-speed gearbox, is compact enough to fit in a sports bag. The drive weighs only around 90 kg and can generate a peak output of up to 150 kW (204 PS) in the ID.3.

Various ID. models will be equipped with front-wheel drive, rear-wheel drive, or all-wheel drive units of different power/torque outputs.

The German manufacturer already plans to produce 500,000 electric motors in Kassel, which will be joined by a Chinese plant in Tianjin.

Together, those two will crank 1.4 million electric drives annually from 2023 onwards.

“Electric drives from Kassel for markets in Europe and North America

In the future, the electric drives for MEB vehicles for Europe and North America will be produced in Kassel. Production of up to 500,000 units per year has been planned. Kassel also works closely with the Chinese plant in Tianjin, where the electric drive is produced in parallel for the Chinese market. Together, the two plants will produce up to 1.4 million electric drives each year from 2023 onwards. This means that Volkswagen Group Components will be one of the largest global manufacturers of electric vehicle drives in the future.”