Though the era of the electrical car is fast approaching, the internal combustion engine, the very heart of the automobile for the last two centuries, still progresses forward. In recent years, valiant attempts at research and development have surmounted the limits previously considered absolute and evolved to meet the increasingly rigorous environmental standards. While the diesel engine has lost a bit of the market’s faith due to a series of events of late, its clear advantages are still prompting the major car manufacturers, particularly European ones, to continue its development.

Of course, Hyundai/Kia Motor Corporation is no exception; the results of the company’s R&D efforts on diesel were apparent in the 2019 Hyundai/Kia International Powertrain Conference, held on October 22nd and 23rd, featuring the latest trends on powertrain development. Here Hyundai/Kia revealed the Smartstream G3.5 T-GDi Engine, the Smartstream D3.0 Engine, and the Smartstream Wet-type 8-speed DCT, all demonstrating the potential of sustainable internal combustion engines.

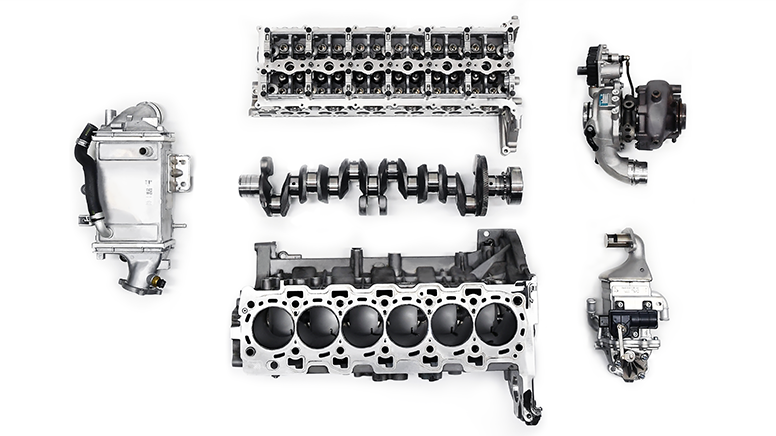

The Korea’s First Inline-Six

Cylinder Diesel Engine,

Smartstream D3.0

Of the engines revealed in the conference, the inline-six cylinder diesel engine, the country’s first of its kind, provided plenty of excitement for the crowd. Named Smartstream D3.0, the engine follows the lineage of the 3.0ℓ V6 S Engine mounted on the 2006 release of Veracruz in being eco-friendly and yet providing high performance. Since the S Engine, the only domestic 6-cylinder, 3.0ℓ engine was the V Engine. But now that advantages of the inline-six cylinder structure has been amply noticed, the structure was chosen for the new Smartstream D3.0.

Inline engines, which as the name suggests places the cylinders literally in perpendicular line, has as long a history as the internal combustion engine itself—they marked the beginning of the technology and boast the longest tradition of all cylinder structures. Admittedly, their structure is rather basic, but due to that they cost less, not to mention being relatively lightweight. The structure also makes for less vibration in engine operation, contributing to ride comfort. Its compatibility with inline 4-cylinder engines, which have emerged as the market’s mainstream, is also quite good.

Due to these advantages, many manufacturers have employed the inline 6-cylinders in their vehicles. Mercedes-Benz is the prominent one to have done so: its recent flagships have debuted with inline 6-cylinder diesel engines, surprising the industry. BMW, too, has been traditionally devoted to the inline 6-cylinder for a number of decades, clearly aware of the advantages offered by the structure.

High-performance,

High-efficiency:

the Next Generation’s Diesel Engine

Fully utilizing these advantages from the start, the Smartstream D3.0 improved across the board in nearly all categories. First, compared to the existing S2 Engine, max power output and torque have increased by 18hp and 2.9kgf·m respectively, showing sizable improvement.

More specifically, the new application of the ball bearing-type VGT(Variable Geometry Turbocharger) has improved the engine’s durability and response rate. Boasting 278hp in engine power and 60kgf·m in max torque, Smartstream D3.0 immediately becomes the highest-ranked 3.0ℓ single turbo diesel engine in the class.

Moreover, the intercooler has been changed from an air-based cooling system to a water-based one, facilitating engine thermal management. The change not only makes the engine warm up faster, but also improves cooling efficiency, the most important facet when supercharger engines are considered.

Fuel efficiency is another facet in which the Smartstream D3.0 has made strides over its predecessors: its compact, lightweight design has led to the increase in the efficiency by 6.2 percent. In addition to the modular structure that increases compatibility with the 4-cylinder engine, the cylinder blocks were made in aluminum, 2.7 times lighter than cast iron, reducing the weight by 32 kg. Meanwhile, of course, the optimized design has allowed the engine to maintain its hardness.

It was not merely weight reduction that contributed to improvements in fuel economy. Crankshaft position and the belt-drive system in the engine were optimized, and low viscosity engine oil was then used to increase friction reduction performance by 17%. In addition, dual-loop composite EGR, which combines the advantages of LP-EGR (Low Pressure-Exhaust Gas Recirculation) and HP-EGR (High Pressure-Exhaust Gas Recirculation), was adopted to improve the response rate. Thanks to this improvement, the amount of intake/exhaust energy loss, as well as that of nitrogen oxide and fine dust emission, was reduced.

The Smartstream D3.0 Engine meets not only the Euro6d emission standards, but it also meets the more rigorous RDE2(Real Driving Emissions Stage 2) emissions. RDE2 standards measure the emission of subject automobiles not in controlled experimental settings but in real roads—the rigors of the standards are such that no more than five diesel engine manufacturers have passed their test.

In the WLPT(Worldwide Harmonized Light-duty Vehicles Test Procedure), the Smartstream 3.0 Engine has shown an 81% reduction in NOx(Nitrogen Oxides) emission by using SCR(Selective Catalytic Reduction). In the RDE test, it succeeded in reducing 90% of the NOx emission. This amounts to a mere 30% of the 6d NOx emission standard baseline.

Outstanding Quietness Completes

the Next Generation’s Diesel Engine

In order to address the noise and vibration typical to diesel engines, the Smartstream D3.0 Engine has adopted several mechanisms to counter NVH (Noise, Vibration & Harshness). A number of sound insulation panels are installed throughout the engine, including the cover, which is made with sound-absorbing material. In fact, the Smartstream D3.0’s noise level was approximately 1.7dB lower than that of the competitors’ inline 6-cylinder diesel engines, demonstrating its excellent quietness. Beyond just the magnitude of the noise, the Smartstream D3.0 surpassed the comparable competitor models in the texture of the engine noise delivered into the cabin.

Embodying efficiency, eco-friendliness, and performance, Hyundai/Kia’s visions in powertrain technology development has created the transcendental Smartstream D3.0 Engine. The engine is a response of the companies to the reality that, despite the advent of the electrical engine in the automobile industry, there will be a long period of coexistence between it and the traditional internal combustion engine. Breaking the stereotypes, the Smartstream D3.0 presents new possibilities for diesel engines of the future. Indeed, it is a pleasing to wonder what the engine will be capable of on real roads.