Tesla expects that this year it will comfortably exceed 500,000 electric car sales, which is possible thanks to significant expansion of its manufacturing capacity.

Here we take a look at all the Tesla production sites, models assigned to them and production capacity.

Tesla recently added Model Y production to its plant in California (since January), while Model 3 is produced also at the Gigafactory 3 (since late 2019).

“Production ramp of Model Y in Fremont has begun, ahead of schedule. Model 3 production in Shanghai is continuing to ramp while Model Y production in Shanghai will begin in 2021. We are planning to produce limited volumes of Tesla Semi this year.”

Tesla installed manufacturing capacity

- Total of up to 640,000 per year (up to 490,000 at the Tesla Factory and up to 150,000 at the Gigafactory 3)

- to be expanded to 740,000 per year by mid-2020

The annualized total vehicle production rate in Fremont (based on 104,891 produced in Q4) is at over 415,000 per year. That’s on par with NUMMI’s peak year of 2006. For comparison, in 2019 the company produced a total of 365,232 electric cars.

“In Q4, the annualized total vehicle production rate in Fremont was just over 415,000 units,about the same rate as the factory under NUMMI reached in its peak year of 2006.We achieved this production rate in spite of Model S/X running on a single shift and before the start of Model Y production.”

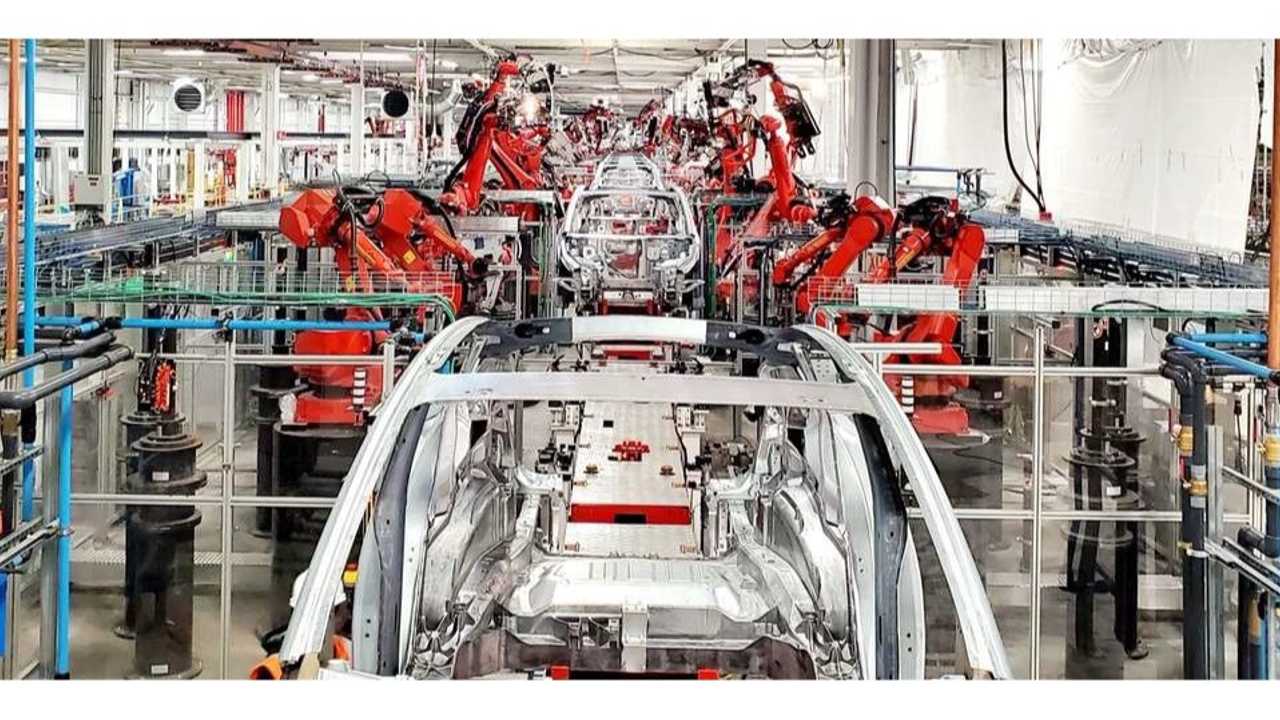

Tesla Model Y body shop in Fremont Factory

Production sites

- Tesla Factory in Fremont, California

- Model S/X (capacity of up to 90,000 annually), Model S since mid-2012, Model X since late 2015

- Model 3/Y (capacity of up to 400,000 annually now and up to 500,000 by mid-2020 after gradual expansion), Model 3 since mid-2017, Model Y since January 2020

- Total output of up to 490,000 S/X/3/Y now (590,000 by mid-2020)

- Tesla Gigafactory 1 in Nevada

- related to lithium-ion cell, module and pack production, energy storage products and drive units

- Tesla Gigafactory 2 in New York

- Related to solar and some energy storage products

- Tesla Gigafactory 3 in Shanghai, China

- “Trial production of Model 3 in Shanghai has begun”

- Model 3 (capacity of up to 150,000 annually), Model 3 since late 2019

- Model Y (expected capacity of 150,000 annually) from 2021

- Tesla Gigafactory 4 in Berlin-Brandenburg, Germany, Europe

- the location of our European Gigafactory to be announced soon

- production expected to start in 2021

- Model 3

- Model Y

- Unassigned models

- Semi: in development, “We are planning to produce limited volumes of Tesla Semi this year.”

- Roadster: in development,

- Cybertruck: in development, unveiled in late 2019, production from late 2021

“Fremont

The production ramp of Model Y started in January 2020. Together with Model 3, our combined installed production capacity for these vehicles is now 400,000 units per year.The ramp of Model Y will be gradual as we will be adding additional machinery in various production shops. After such expansions are done by mid-2020, installed combined Model 3 and Model Y capacity should reach 500,000 units per year. We will start delivering Model Y vehicles by the end of Q1 2020.

Shanghai

We have been gradually ramping local production of battery packs since late Q4 2019. The rest of the Model 3 manufacturing processes are running as expected. Due to strong initial customer response in China, our goal is to increase Model 3 capacity even further using existing facilities.We have already broken ground on the next phase of Gigafactory Shanghai. Given the popularity of the SUV vehicle segment, we are planning for Model Y capacity to be at least equivalent to Model 3 capacity.

Berlin-Brandenburg

We are moving forward with our preparations near Berlin, which we have selected as the right place to build vehicles for the European market due to a strong manufacturing and engineering presence in Germany. The first deliveries from this factory are expected in 2021.”

One of the key improvements for Tesla is the launch of the Gigafactory 3 in Shanghai, where the entire process was highly simplified, compared to the former NUMMI plant in California, adapted to EV production: