While the Tesla Model Y deliveries will start in just a few days, we are still trying to anticipate the juicy technical details it still hides. How will Tesla cut down on wire harnesses? What role will casting play in its body construction? This last question had the contribution of many experts that got in touch with us. Anyway, there is always room for one more, and that is where Holger Erker, from IPE Engineering GMBH, fits in: he believes the cast parts will be bigger and more than previously thought.

He has prepared the images in this article and also a document about everything this car’s body may present. The level of detail Erker has put in his report made it worthy of an article for it alone.

The German engineer tells us how Tesla has created the car structure based on the images Tesla released:

“As it appears from the Q4 2019 report photos and released pictures, the Model Y body structure is build up as a multi-material mix unibody similar to the Model 3’s.

It could be seen true that, in principle, the Model Y body is built from four major components – rear cast, front cast, BS Asm LH (bodyside assembly left hand), and BS Asm RH (right) – and a few further skin panels and closure parts.”

In other words, Tesla probably created two massive cast parts: the ones that have to hold the motors. Arnaud Contet mentioned the powertrain would be very happy in a stiffer structure than stamping could ever achieve.

With images that do not adequately show the front structure, Erker did his best with what he had in his hands.

“The bodyside (BS) is built up as a three-layer structure. The structural BS inner and outer is made from HSS (high-strength steel) or UHSS (ultra-high-strength steel) tailored blank stamped steel panels. Because of the high tensile strength, the forming of the panels can be done only with hot pressing. Therefore, we can find the heat marks visible on the panel skin.

The interesting part on the BS is definitely the upper A-pillar and roof rail section. It looks like this section is made from separate pressings which are then welded to the door rim panels, forming the final structural bodyside – picture #3 (below).”

The main cast part will be the rear body structure.

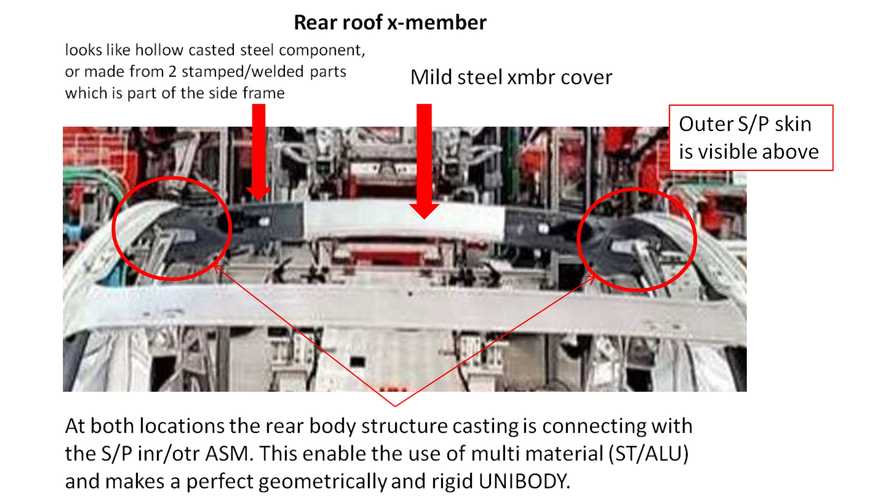

“The rear body structure is formed from one super large cast part. The casting includes the rear long members, cross-members, and all mounting points for the later drivetrain assembly, the inner wheelhouses and also defines the rear vehicle geometry – X/Y/Z coordinates. What we believe to identify also on picture #1 (the main one) is that the cast is containing a C-pillar structure that is going all the way up to the rear roof cross-member. This would make perfect sense in order to simplify the body structure and the geometrical build process – picture #4 (below).”

Erker shows a good knowledge of the tools used in the process and makes interesting estimates.

“The casting process must be definitely very well advanced because the size and weight of the cast parts are beyond what is known from today’s auto parts. The process could be done with HPDC (High-Pressure Die Casting) on a cold chamber pressure casting machine with vacuum support to avoid casting defects such as pores, bubbles, cracks, etc.

Our rough assumption is that the rear structural part could weigh around 40 to 45 kg. As a reference: the cast rear long member of the Audi A8 is weighing approximately 10.5 kg.”

According to the German specialist, Tesla probably had a lot of work getting this done.

“For the rear body structure, we assume the closing force required would be above 6.000 metric tons. Usually, the maximum shot weight for aluminum alloy parts is around 10 kg, due to machine limitation in closing force capacity. The standard closing force is around 1.500 to 2.000 metric tons.

Only very few machine suppliers worldwide have the experience to build cold chamber casting machines with 4.000 or a maximum of 5.500 metric tons of closing force. Therefore, the machine at Tesla must be a special custom-build and quite gigantic.”

The issue is that this machine has to be quite fast to keep up with production requirements. Erker also gave us his professional opinion about that.

“Assuming that the complete casting cycle – including all handling and preparation – could be managed in less than two minutes, the maximum annual casting machine output would be in the range of 150,000 parts. That seems OK for volume production. Since also the front structure would be a cast, at least two of those machines should be sufficient for the production.”

Erker is just concerned with the quality control of these parts.

“Key to the concept is to manage a consistently high-quality production output on the casting machines.

Each cast part should go through an X-ray test to verify that no material defects are inside. It would be detrimental if this part would fail during vehicle operation.

Investment for the casting machines and dies are presumably very high but can be compensated with the savings from the body shop tooling. CAPEX wise, it might be even.”

If all that is feasible, the manufacturing gains would be amazing.

“The body assembly shop most probably consists of two frame lines, two body side subassembly welding cells and a BIW (body-in-white) closure mounting and finish line. That would be roughly only 60 percent of a conventional body shop.

The total production time of a Model Y body-in-white compared to a conventional stamped steel body will be substantially lower. Considering the net process time for the underbody section, only the casting would eliminate between 1.000 to 1.500 weld spots, at 5 to 7 seconds each. That would total at an approximately 120-minutes net process time-saving.

If Tesla is able to manage the production process with high quality, production costs

will be definitely lower than Model 3’s. Guess what would happen if the full-body frame casting machine would work as shown in their patent application…”

We’re still waiting for Tesla’s official word on the “advanced manufacturing methods” Elon Musk promised the Model Y would have. We only hope the company does that before people start to disassemble brand-new vehicles to figure that out by themselves.