The need for improved fuel efficiency is a key factor in the development of all-wheel drive (AWD) technologies today. BorgWarner, an established global leader in the advancement and supply of AWD systems, delivers breakthroughweight and efficiency improvements, along with the necessary performance enhancements in today’s AWD systems.

With the development of these next-generation actuators for AWD systems, BorgWarner is contributing to reduced costs and helping to offset the financial challenges from other vehicle components in pursuit of the goal of cost-neutral hybrid vehicles. At the same time, the need for actuators delivering the same or improved torque transfer levels, while reducing complexity and weight, continues to grow.

Next-Generation AWD Systems

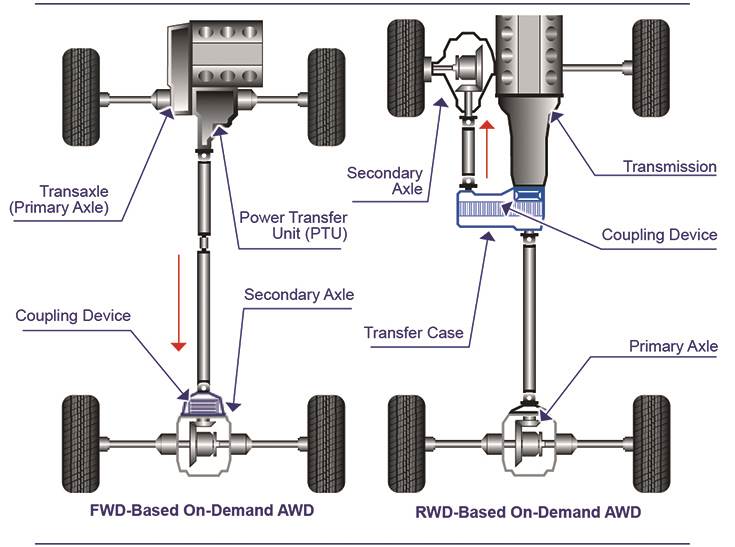

BorgWarner, which is a longstanding partner to global automakers, supplies OEMs with AWD couplings and transfer cases. The mechanical processes for both front and rear wheel based on-demand AWD systems are nearly identical and are differentiated only by the vehicle drivetrains they support.

Different layouts and AWD drivelines supported by sixth-generation actuator systems.

A wet multi-disc clutch connects an ingoing and an outgoing shaft for torque transfer and control in both AWD systems. BorgWarner has a wide range of options for applying compression force to the clutch package to support different customer requirements. The hydraulic actuator, which applies a variable force to the clutch package utilizing hydraulic pressure and a working piston, is central to both AWD systems. Usersare able to control the working pressure within the system and monitor the torque transfer to adapt the performance of the AWD system to fit driving conditions. By monitoring the vehicle network, users can select a torque level to optimize system performance for their unique driving situation. This integrated system will also react to requests from other integrated vehicle components, such as ESP, to optimize performance in critical situations.

Weight reductions have been achieved with improved or same performance over the generations. Index 100 for GenI in 1998.

BorgWarner introduced its first (Gen1) AWD hydraulic actuation solution in 1998 and now produces more than 1.5 million GenV couplings per year. Initially, these technologies useddifferential speed-driven pumps to create instant pressure, which was controlledthrough the slippage between front and rear axle. This method has been improved over subsequent generations of actuators, but the main continuous improvement focus has been onreducing both the complexity and weight of these systems. Throughout the development of these next generations, coupling weight has been consistently reduced , while achieving driving performance enhancements at the same time. As product sophistication increased, the differentially driven pump was removed in the fourth generation and replaced by an electrically driven pump, accumulator and control valve, which eliminated the need for a pressure sensor. For the fifth generation, the accumulator, filter and pressure control valve were all removed and replaced by the current centrifugal pump.

Gen VI System Innovations

This patented centrifugally controlled piston pump, which is critical to the performance of the GenVI system, not only creates the pressure in the system, it also controls it. The 6-piston axial pump produces highpressure levels withgreater efficiency. Through the use of itscentrifugal control valves, the pump creates a correlation between the rotating speed of the motor and the pressure within the system.

Pressure and rotational speed relationship from centrifugal pump mechanism.

Pressure and rotational speed relationship from centrifugal pump mechanism.

Piston drum cross-section with one of three centrifugal levers which control pump pressure.

Because of this connection, the system works bestwhen driven by a brushless DC motor (BLDC) wherespeed is the setpoint. The balancing force of the steel ball in the check valve sets the pressure, depending on the motor speed. This enables highpressure accuracy and low hysteresis, providingexcellent response times atany setpoint.

A target specification, based on customer feedback and findings from internal tests, was developed for this next generationactuator.This led to anew concept design:

– BLDC for improved durability,smaller size and enhanced thermal capability

– Integrated ECU for lower costs, reducedpackage sizeand more robust EMC by removal of the cable harness

– Alignment of the ECU and stator diameters, which utilize the visible mating of interconnects between the ECU and the stator to improve assembly efficiencies and minimize product cost.

– Dry stator and ECU to avoid compatibility issues between oil, electronics hardware and interconnects

– Wet rotor to eliminatethe dynamic radial seal between pump housing and motor shaft

– Sensorless motor control including an optional position sensor if necessary.

BorgWarner GenVI hydraulic actuator cross-section with integrated ECU.

BorgWarner GenVI hydraulic actuator cross-section with integrated ECU.

To maximize the benefits ofthese improvements, the BLDC motor is both designed and assembled in-house. This is required to optimize the system, as well as tomanageany potential compromises between the subsystems while improvingperformance and cost. BorgWarner’s experience on larger e-machines,combined with this full system ownership and development of the motor control algorithm, is key to system optimization and the company currently has multiple BLDCs in production and development in anticipation of future needs.

Reduction of Weight and Package Size

The new, optimized GenVIactuator systems have reached new levels of weight reduction, more than 40% over previous generations. This also results in a weight reduction of approximately15%when compared to conventional AWD couplings. The reduced size of the e-machine, combined with the integration of an ECU and the general flexibility of a hydraulic actuator, allow for a significantly smaller system, which helps manufacturers to optimize their packaging.

BorgWarner GenVI AWD coupling.

Improved Accuracy and Response

Due to the relationship between motor speed and centrifugal mechanism pressure within the pump, the use of a BLDC withspeed control supports the pressure accuracy withinthe system. The response time,or the time required for the new value to be reached after a request for altered setpoints, is also improved with this system. This is achieved by enhancing flow control of the pumpby the motor controller when it reaches normal operating temperature.

Improved Durability

Wear on the brushes and the commutator in a DCmotor limit its operational lifetime. These limits do not exist with a BLDC motor,since mechanical contact is not required forcommutation. The use of a dynamic radial seal is also not required with BorgWarner’sBLDC motor, which further enhances motor durability and life.

Enabling ECOOperation

The use of a BLDC in the GenVIactuator, with its virtually unlimited start/stop capability, is also a key enabler of ECOmode. In ECO mode, the system’s energy consumption is reduced becausethe motor is completely shutoff in conditions where no torque transfer is required. Oil churning losses can also be minimizedwithin the systemthrough theintegration of a shutoff valve for the lubrication flow into the friction disc package.

Multiple System Efficiencies

The GenVI actuator was intentionally designed tosupport multiple system types. This technology can work as an independent node connected only to the power and the vehicle network, controlling the complete system functionality including full diagnostics and vehicle dynamic controls.

The GenVIsystem is also effectivefor use as a smart actuator that works on request of a main ECU, with reduced diagnostics andability to communicate its status. It’s also suitable to be used as a motor actuator,with an integrated connecter and no electronics, fully controlled by a remote ECU. These possibilities for reuse become even more important as software functionality and complexity increase.

The development of GenVIwas driven by the need for a new AWD actuator, but the motor and ECU configuration were developed with additionalneeds in mind.Most of the software functionality already developed can be reused by combining the motor with a different kind of mechanism to control other vehicle components.

To further support this multifunctional approach, actuators to control disconnect solutions for both AWD systems and electrical axles, are now being developed along with park-lock solutions and oil cooling pumps. The overall impact of thehigh volumeAWD actuator production, along with reduced development needs, deliverbenefits of increased manufacturing efficiency and speed for the OEM.

Summary

With its introduction of theGenVI actuator system, BorgWarner continues its tradition of delivering innovative, competitive and refined solutions to the market. These breakthroughs not only enhance the development of systems for hybrid or pure electric vehicles, they also bring improvements to other subsystems. The importance of the new actuator is that it combines great performance with competitive advantages in system packaging, weight and efficiency. These improvements have been achieved through the introduction of a BLDC motor along with the high level of integration with actuator components. Further, this is all enhanced by the in-house design of the BLDC motor in combination with the control algorithms for the motor, without which this level of system optimization would not be possible.

The Authors

– Christian Mansson, Development Engineer, Mechatronics, BorgWarner PowerDrive Systems

– Mans Ranaker, Director, Driveline Engineering, BorgWarner PowerDrive Systems

– Per Soderberg, Development Engineer, Motor Design, BorgWarner PowerDrive Systems

/feature/borgwarner-nextgen-awd-actuators-spell-gains-for-oems-56410 BorgWarner reveals next-generation AWD actuators BorgWarner’s next-gen AWD actuators spell gains for OEMs https://www.autocarpro.in/Utils/ImageResizer.ashx?n=http://img.haymarketsac.in/autocarpro/807dcec8-eedb-46eb-97c5-825c73b7e930.jpg