Seamless Entry

It has been said of art and vehicle design that only the arrangement is new. In other words, everything has been done before and it is only which elements we bring together and how we compose them that make a new design truly unique.

This was our mindset when we designed the seamless entry power side doors for FF91. We were given complete freedom to reimagine how users interact with their vehicles and developed a unique seamless entry system.

One of the two most prominent features of the design is the independently opening rear-hinged rear passenger doors. While the rear-hinged rear doors are not new in the automotive industry (the 1964 Lincoln Continental utilized them), the seamless powered door operation with no door handles is new.

Before I joined Faraday Future I was inspired by auto-opening doors while on a trip to Japan. If you haven’t visited Japan, you would be surprised to see that most taxis have auto opening rear doors. The rear doors opened for me as I approached the taxi, and since I didn’t realize that the driver was the one operating the door, I grabbed the door to close it but was promptly reminded to not touch the doors so I would not break the mechanism. It made me think, why can’t all doors be powered?

Another example of an everyday issue with car doors is when they inadvertently hit other adjacent cars. When I bought a new car, my young son was not used to the large rear doors and accidentally slammed it into the car beside us. Luckily the car wasn’t damaged but it made me think, what if a vehicle can stop this from happening?

Fast forward three years when we started the FF91 project at Faraday Future. We started developing our ideas from a clean sheet of paper. I wanted unique doors and strived to incorporate changes that solved these issues and more. We added new technology that included sensors, cameras, and intelligent software. We could solve some of the problems that people encounter every day when they are out in their vehicles.

Two years of hard work and we had the prototype built. A seamless automatic entry powered door system that sensed objects and prevented them from hitting other cars was developed in our Beta Vehicle. Production tools were developed and tuned and the Gamma vehicles were built for final testing.

I also wanted to understand how people used doors during a rideshare situation. I wanted to observe the use of the doors and what customers deal with in real-world situations so I signed up to be a driver for Uber and Lyft and drove 1,000+ miles to experience various situations in and around Los Angeles. I encountered many situations such as not being able to find parking to drop off or pick up a passenger — so pulling to a stop for a drop off requires a fast entry or exit. Other experiences included passengers needing to quickly enter the vehicle with luggage or being occupied on their phones having conversations. These and many other observations made their way into the design of FF91.

How did we do it?

To make the seamless entry happen, the FF91 required the invention of unique mechanisms, sensors, electronics, and software, as well as a very rigid door and body structure. In addition to simple entry and exit, we also wanted to provide users a way to get into the vehicle that could be operated while they were holding groceries, or maybe even while holding two cups of coffee! We achieved this by inventing a new button design that allows the opening of the doors with a touch of a finger.

The unique integrated design required intense collaboration from sketch to production tools to execute. In addition, the frameless windows enabled a flush glass look along the full side of the vehicle.

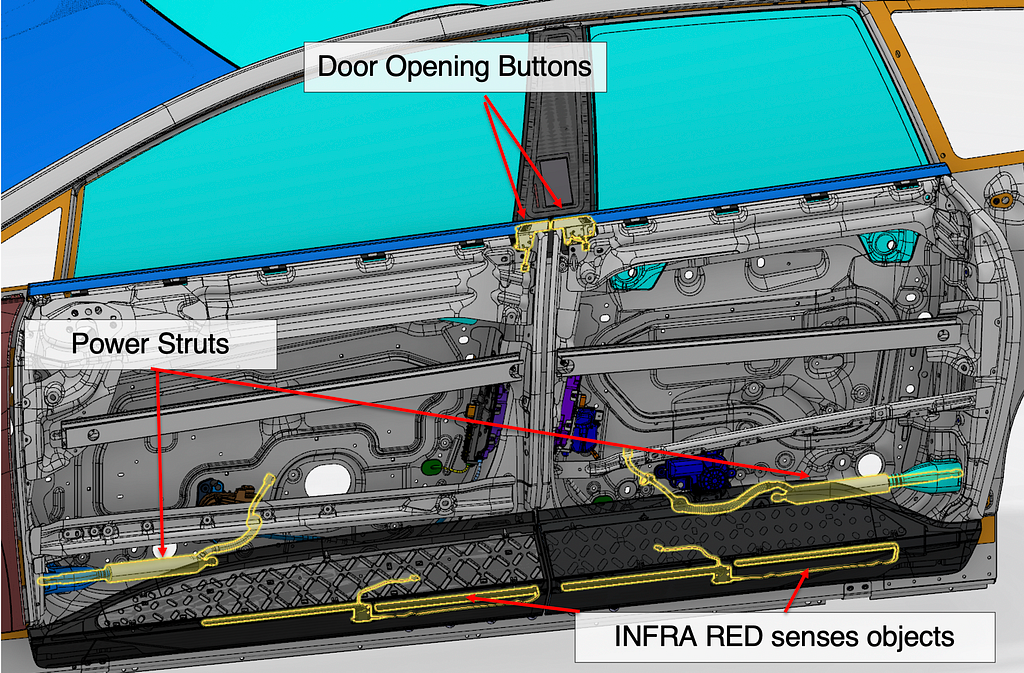

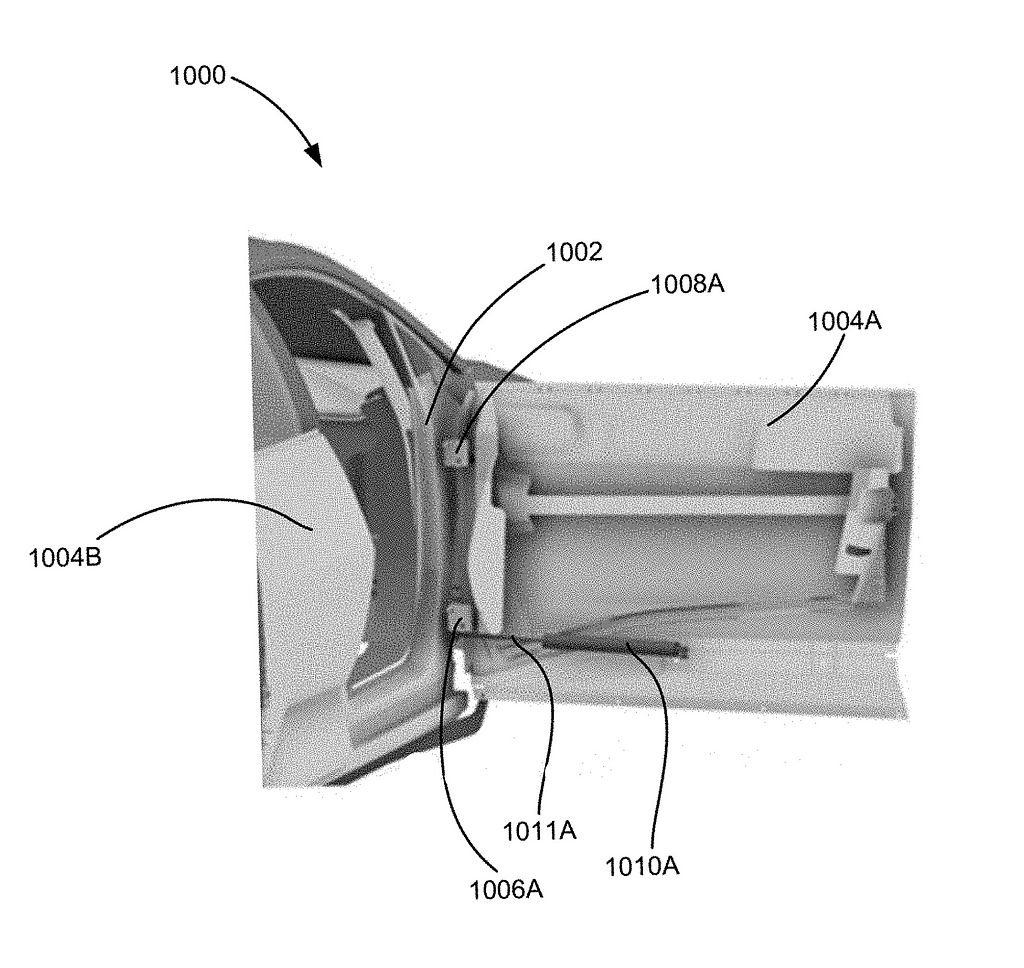

To engineer the seamless door function, we utilized a uniquely designed cinching e-latch, unique power strut actuators with an electronic brake, hidden infrared sensors and cameras, a unique door opening module with accelerometers, and in house designed door control module with 1,000’s of lines of code to operate the system with quality and smoothness.

We built a testing rig that would put the door in multiple grade situations to fine-tune the feel of the door while integrating the mechanisms inside the door to make it function.

As a result, the user will enjoy a unique entry system that enhances the everyday use of their doors.

The Doors of FF 91

We designed the FF91 with flush side glass with a patented door opening module in trim (our door opening module patent application https://patents.google.com/patent/US20190063139A1/) and rear-hinged coach doors with full drop frameless windows.

The doors will sense objects that you may not be able to see (such as a fire hydrant) and stop the door from hitting objects by turning on an electronic brake (manual or powered operation).

Inside the door

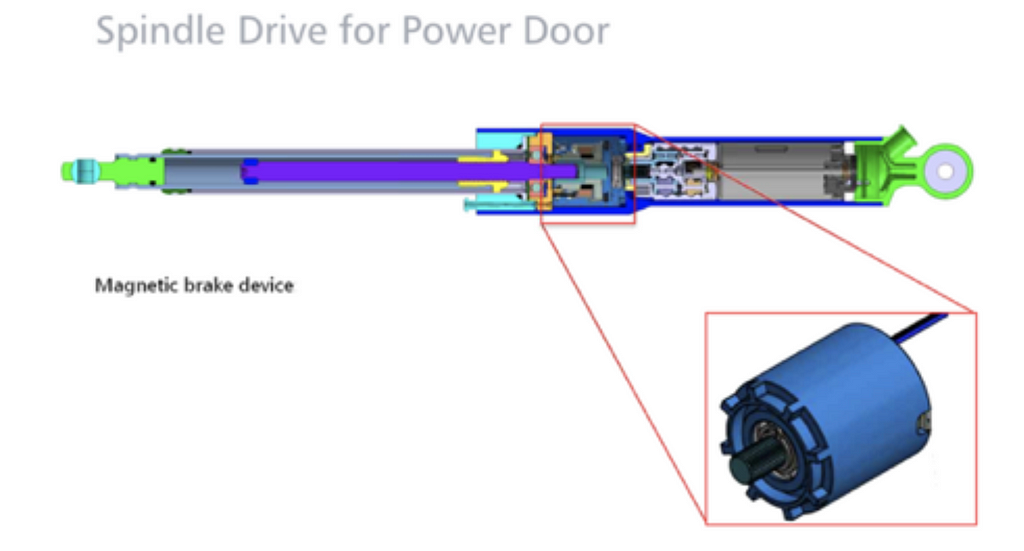

We chose a horizontal actuator for more torque and to allow the windows to full drop into the door:

The function of the magnetic brake inside the door actuator is to provide an infinite stopping position of the door and provide protection for the door when an object is sensed by applying a 100% brake.

Patent US9963020 integrates the power door strut into the hinge: https://patents.google.com/patent/US9963020

Patent for the FF91 velocity profile: https://patents.google.com/patent/US10407968B2

Recently allowed patent application for System and method for opening and closing vehicle door: https://patents.google.com/patent/US20190024435A1

There is also a unique feature of the FF91 that allows a user to operate the doors of the vehicle with your voice and watch:

Being an engineer, you get to create things, new things for the betterment of society, and for the customers and users of your products. I had the unique opportunity to take all of my past experience and observations and create a truly unique power-operated door system from the ground up for FF91 and I’m excited to share this one of a kind system with the world through my work at FF.

About the Author

Matthew Partsch is the Director of Engineering for FF’s Body and Closures team. He leads the engineering team to design, test, and validate the Body in White and Closures systems. Matthew has over two decades of experience in the automotive industry and vehicle technology, leading projects for American automakers.