My work as an Aerodynamicist is where art and science meet, come together and do a delicate dance. It’s then about marrying the two to yield a product that’s both beautiful and aerodynamic.

At Faraday Future, aerodynamics development commences not with engineers, but with our studio designers. As soon as pencils touch paper, designers are sketching our future vehicles with aerodynamics in mind — from sleek silhouettes to hidden ducts that redirect air to favorable places around the vehicle.

Instilling the science of aerodynamics in the mindset of our studio designers facilitates the harmony of both engineering and aesthetics — a challenge that is omnipresent with automotive manufacturers. Some auto manufacturers separate their aerodynamics team from the design studio and group them with the rest of their engineering team — sometimes separated by vast geographic distances. At FF, aerodynamicists sit side-by-side with our designers, assisting and collaborating with them throughout the design of our vehicles.

One of the features that customers value in an electric car is range. Therefore, we dedicate a lot of effort to understanding how air moves and behaves around our cars, which helps us minimize air resistance, and in turn, maximize range performance. This is key.

It’s not just aerodynamics that impact range performance. A few other factors impact the driving range of an EV, such as battery technology, mechanical efficiency of the motors and other moving mechanical components, the cooling system, the rolling-resistance of the tires, and the overall mass of these and other components. However, unlike most of these, aerodynamics does not entail physically adding or removing hardware to yield a better range. It’s primarily a science of cleverly shaping the exterior of the car. In terms of battery size and cost, a more aerodynamic vehicle shape requires a smaller battery, which would, in turn, yield a lower mass and less expense to achieve a desired range.

The tools we use for our aerodynamic development are similar to the state-of-the-art tools used by other car manufacturers, namely, computational modeling software, computational fluid dynamics (CFD), and wind-tunnel test facilities. CFD helps provide an in-depth understanding of how the air behaves around our cars. However, given that it is a computer simulation attempting to model the physical world, there are inherent inaccuracies; therefore, we also use wind-tunnel facilities to validate our simulations and make corrections to our computer models. Still, the level of correlation we’ve achieved with our computer models to real-world physics has been outstanding.

We have created a bespoke methodology within CFD that helps us find optimal solutions for a set of constraints quickly. For example, we have the ability to semi-automatically sweep through a matrix of geometrical changes and assess each change through our CFD software, which ultimately helps us achieve an optimal design.

These custom tools are particularly useful in the early stage of the design process, where studio designers can take advantage of the geometrical freedom that exists early in a program, and consider different vehicle proportions. As previously mentioned, one of the strengths of CFD is being able to visualize the dynamics of the air. This is both useful for aerodynamicists and studio designers, who are typically reliant on the visual aspect of design. Although the video below might look like it was created by an artist, it is a rendering of the FF91 created by the CFD tools we use at FF. It visualizes the chaotic air behavior at the wheels, side-view mirror, and the rear of the car.

The wind-tunnel facilities we use to validate our CFD simulations mimic a vehicle moving through air, but do so by moving the air around the vehicle. A test vehicle is placed in an enclosed room and secured to its surroundings, while air is blown over and around it using a large and powerful fan. To more accurately replicate the physics of an actual moving car, these test facilities are equipped with the ability to rotate the car’s tires/wheels and move the ground beneath the car. We ensure to use state-of-the-art facilities that have these capabilities.

In our pursuit to produce efficient, competitive, and disruptive world-class electric vehicles, we’re taking a detailed look in our development process to identify improvement opportunities to ensure we achieve this — this includes how aerodynamics is executed.

FF91’s striking and beautiful design and streamlined aerodynamics are achieved not only by the extensive effort of the engineers and studio designers but also through the marriage of science and art.

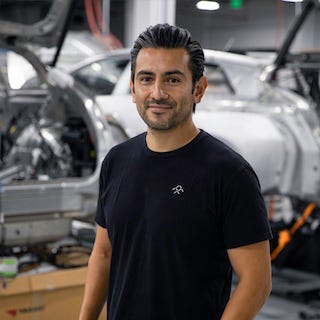

About the Author

Sergio Gonzalez was FF’s first aerodynamicist, and after five years with the company, now leads our aerodynamics efforts as Aerodynamics Manager. Prior to his experience at FF, he worked in the motorsports sector for teams in Formula 1, IndyCar, WEC, and WRC.