A South Korean small and medium-sized company has established a mass-production system for all-solid-state batteries that are seen as “dream battery”. All-solid-state battery is seen an innovative product that will lead future energy industries such as electric vehicle and energy storage system (ESS).

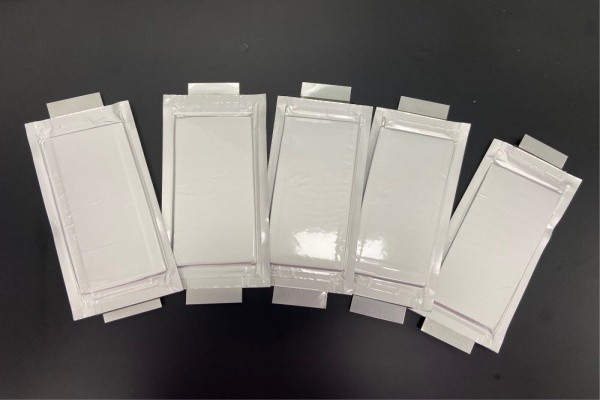

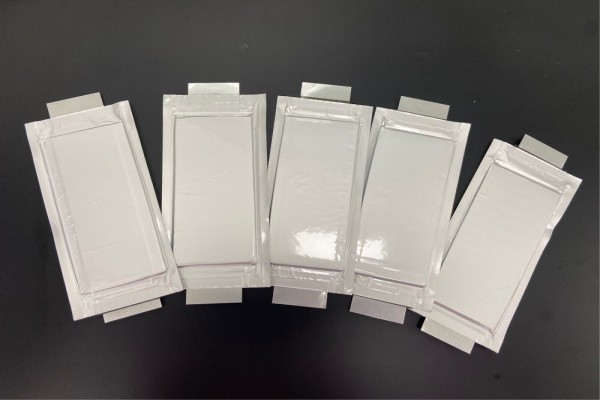

TDL (President Kim Yoo-shin), which specializes in materials and components, announced on Monday that it has set up production lines that are able to mass-produce 80MW pouch-type all-solid-state batteries for ESS annually at its plan located in Energy Valley in Naju-si.

The company, which started off its business in 2008 by manufacturing solid oxide fuel cells (SOFC), was able to develop its own all-solid-state battery manufacturing technology by receiving electrolyte synthesis, battery manufacturing, and cathode complexation technologies from Korea Institute of Industrial Technology (KITECH) over a course of three different times between 2012 and 2020. It then received $6.26 million (7.2 billion KRW) of investment from Korea Development Bank and POSCO and constructed all-solid-state battery production lines on a 2,600m2 land within Energy Valley that is in Naju Innovation City.

All-solid-state battery is a next-generation rechargeable battery that replaces organic electrolyte of lithium-ion battery with nonflammable solid electrolyte. It has low ignition risk and high energy density and is able to materialize large capacity. All-solid-state lithium rechargeable battery is drawing attention as the medium and large-scale battery market grows.

TDL has secured a technology that is able to synthesize all-solid-state electrolytes through its patented technology that guarantees low manufacturing cost and high quality and makes the electrolytes into a large sheet. It also lowered sintered temperature, which is a weak point of oxide solid electrolyte, to a certain level and resolved weak points of sulfide solid electrolytes such as interfacial resistance and dendrite (inorganic precipitate). It has a system that is able to respond to various demands by designing and manufacturing batteries for various purposes.

The company is supplying Its all-solid-state batteries for ESS to Korea Electric Power Corporation and local governments first through ESS packaging companies by using a special case system. It is also planning to supply stabilized batteries for defense industry purpose. It is looking to request a preliminary screening to be listed on KOSDAQ in September next year and launch batteries for electric vehicles within the next three years.

President Kim of TDL said that the company believes that it is able to enter the all-solid-state battery market early by mass-producing batteries for ESS and developing batteries for electric vehicles at the same time and that it is looking to become a leader in next-generation batteries in the global market as well.

Staff Reporter Kim, Hanshik | hskim@etnews.com