Manufacturing service provider FreeFORM Technologies is using binder jet 3D printing technology from ExOne to produce lightweight tooling for the automotive sector.

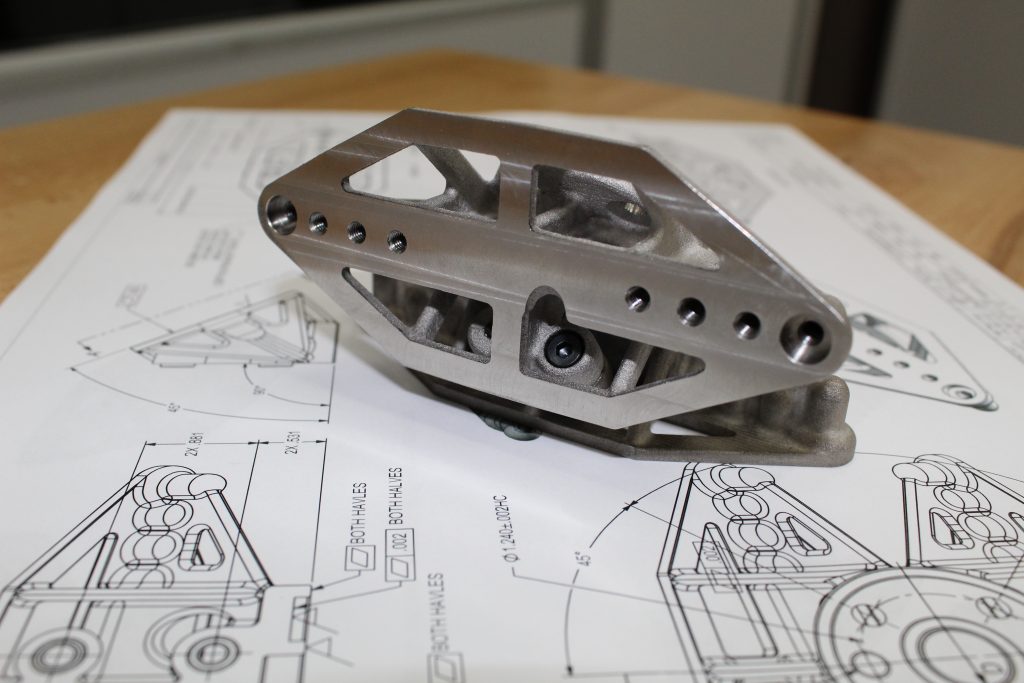

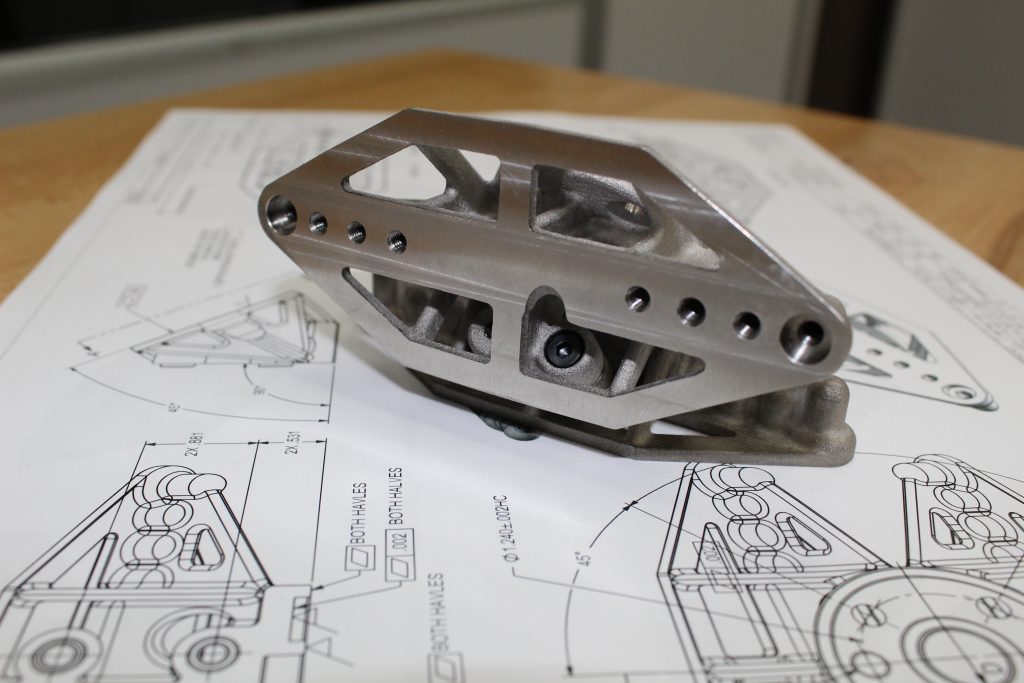

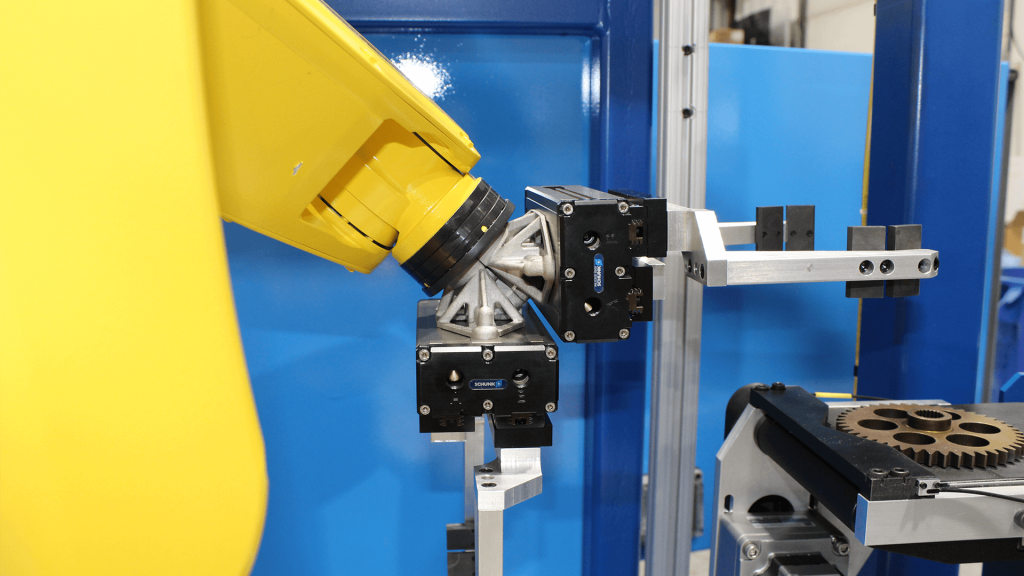

Specifically, the company recently 3D printed a complex end-of-arm tooling component for industrial automation firm Allegheny Electric Service. Built using 17-4PH stainless steel, the part is designed to be integrated with a six-axis FANUC robot as part of an automated part inspection system.

By opting for an ExOne Innovent+ 3D printer over a metal SLS system, FreeFORM was able to cut manufacturing costs down from $672 with laser printing to just $150 with binder jet, all while minimizing the weight of the part.

Chris Aiello, VP of Business Development at FreeFORM Technologies, states, “This project shows exactly why we started the company, to help customers solve challenging problems. Binder jetting was really the only way to go for this project. It was one-fourth the cost of DMLS, and we did it in a strong material that reduced the payload on the robot. As Allegheny Electric Service rolls this technology out, it’s going to be a bigger savings for their customers.”

Optimizing automotive inspection

When Allegheny Electric sought out a manufacturer, what the company needed was a durable and lightweight coupling piece for the arm of its inspection robot. The system as a whole was required to pick up and place six different parts on an inspection line. Running non-stop across three shifts, the number of parts inspected by the company’s robots can be as high as 500,000 every year.

Typically, the stainless steel piece would be 3D printed in a carbon fiber-reinforced polymer or machined out of a strong, lightweight metal such as aluminum. While the initial prototype was 3D printed in a reinforced composite, the weight requirements and processing volumes of the project meant that the composite simply wasn’t durable enough.

“It would have had less life, and they couldn’t afford the risk of dropping the part into the inspection station, which costs several thousands of dollars,” explains Aiello. “The rigidity and strength just wasn’t there for the biggest parts.”

Furthermore, machining the part out of aluminum would have pushed the upper weight limit for the FANUC robotic arm, rendering it a risky choice. Using generative design software, FreeFORM was able to strike a perfect balance between durability and weight, 3D printing the part out of stainless steel with a final mass of just 95 grams.

Aiello adds, “They could have gone with a simpler design in aluminum but the part would have actually been heavier to get the same strength as 17-4PH. By going with this kind of organic generative design, they were also able to reduce the overall payload on the machine, so it’s likely going to extend the life of the robot for the customer.”

A new route to tooling production

With the completion of the project, both Allegheny Electric and FreeFORM now have a tried-and-tested, affordable method of durable part production. FreeFORM also claims the metal parts it 3D prints using ExOne systems are equivalent in quality to those it traditionally manufactures, but without any of the tooling or geometric constraints.

“We are always working within the design constraints of traditional manufacturing. Now we can focus on design intent and process optimization to meet or exceed our customers expectations,” said Jake Shannon, Design Engineer at Allegheny Electric Service. “We will definitely continue to offer our customers end of arm tooling produced with binder jet 3D printing. An important feature for us to offer our customers is how this technology reduced the payload on the robot.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the binder jet 3D printed component, which was optimized for both weight and costs. Photo via ExOne.