Nominations for the 2021 3D Printing Industry Awards are now open, tell us who is leading the industry now.

Binder jet 3D printer manufacturer ExOne has teamed up with Tennessee-based start-up Maxxwell Motors to develop a unique 3D printed copper e-winding design for the latter’s axial flux electric motors.

The motors are used in electric vehicles (EVs) and industrial devices, and face limitations regarding efficiency and design when manufactured via current manufacturing methods. Now, the partners have proven how deploying binder jet 3D printing for the new e-winding design can save time, money, and deliver improved performance.

“When we 3D print it, a lot of the challenges just go away, and we can actually improve the performance of the motor itself,” said Michael Paritee, CEO of Maxxwell Motors. “At Maxxwell, we’re taking the most sustainable, and additive manufacturing, point of view as possible to truly improve efficiency, reduce waste and optimize performance.”

ExOne’s binder jet capabilities

As a binder jet additive manufacturing specialist, ExOne has expertise ranging across a variety of different materials and applications. In June, the company reached a significant milestone with its Metal 3D Printing Adoption Center, having delivered more than two million metal parts to its customers worldwide.

Just last week, the company revealed it had entered into a definitive agreement to be acquired by competitor Desktop Metal in a deal that will see two of 3D printing’s biggest binder jet system manufacturers join forces. Expected to be finalized in Q4 2021, the acquisition will seek to “increase the penetration of binder jetting” through pooling both companies’ materials, reducing overlap and harnessing the synergies between their respective technologies.

Over the past six months, ExOne has carried out an expansion drive that has seen it acquire the ‘AMClad’ assets of Freshmade 3D and launch its Metal Designlab 3D printer. The firm has also worked with Ford to develop a new aluminum binder jetting process, and Celwise to 3D print tooling out of wood-based materials, with both technologies expected to be added to Desktop Metal’s portfolio upon completion of the acquisition.

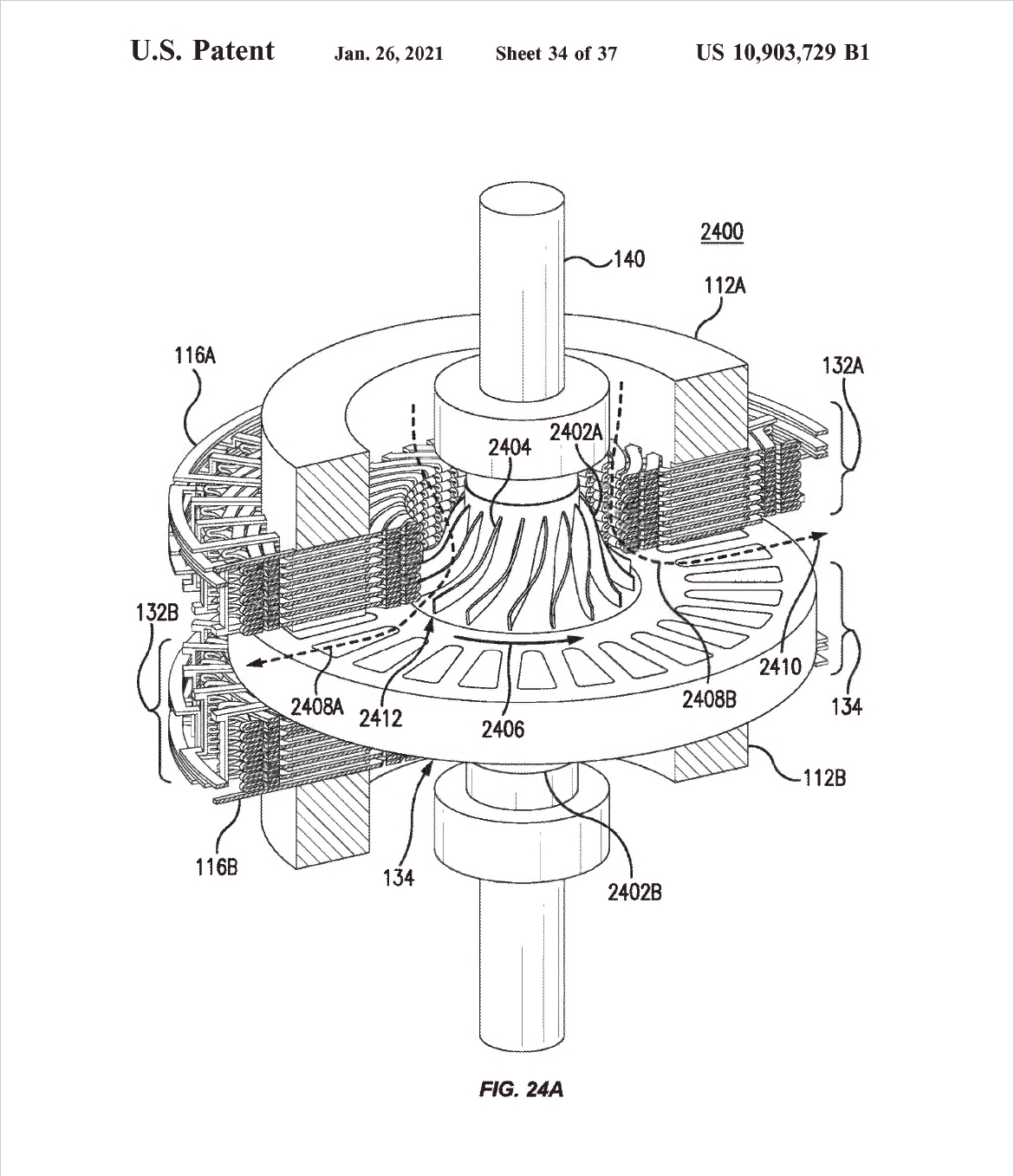

The new copper e-winding design

Optimized copper windings and rotors in electric motors are key to enabling the automotive sector’s transition to hybrid and pure electric vehicles, as countries around the world announce bans on the sale of conventional petrol and diesel cars. However, manufacturing such windings via current methods can prove costly and inefficient, while also providing limited design freedom.

Maxwell Motors was founded in 2018 with the goal of improving how electric motors are designed and manufactured. Holding nine US and global patents, the company has since launched two products, a 10kW air-cooled motor generator and a 150kW liquid-cooled motor.

Now, the company has partnered with ExOne to leverage binder jet 3D printing to prove a new high-efficiency copper design that overcomes many of the challenges associated with the traditional manufacturing of e-windings. Additional development and testing of the design is now underway, and the partners’ ultimate goal is to 3D print winding assemblies as a monolithic piece.

Binder jetting the e-winding as a single piece would eliminate the need for coil wrapping, bending, tooling, and welding of individual parts together. As such, the part would require fewer manufacturing steps and less energy utilization, while also reducing the amount of material waste produced.

Manufacturing the winding assembly component via binder jetting would also increase the part’s efficiency and improve its performance, the partners say, with the technology’s relative affordability a further bonus.

“The ExOne team is proud to work with both traditional manufacturers and visionary start-ups working to change the world with innovative concepts such as these,” said John Hartner, ExOne’s CEO. “As the automotive industry enters a new era of electrification, our world-class team of engineers stands ready to help solve some of the most pressuring challenges with our binder jet 3D printing technology.”

Binder jet 3D printing for automotive

ExOne’s binder jet 3D printing technology has also been leveraged elsewhere in the automotive sector, specifically by manufacturing service provider FreeFORM Technologies to produce lightweight tooling. By opting for an ExOne Innovent+ 3D printer over a metal SLS system, FreeFORM was able to cut manufacturing costs down from $672 with laser printing to just $150 with binder jet, in addition to minimizing the part’s weight.

Meanwhile, car manufacturer Volkswagen has announced plans to use binder jet 3D printing to manufacture components at its main plant in Wolfsburg, Germany, through a partnership with 3D printer OEM HP and industrial manufacturing firm Siemens. Volkswagen will reportedly become the first car maker to use the technology within its production process, and hopes to reduce costs and increase the productivity of its manufacturing operations.

In May, engine manufacturer Cummins Inc revealed it was in the process of finalizing approval for its first metal 3D printed production part, with official production slated to begin later this year. The firm printed the part using a binder jet 3D printer from GE Additive as part of an ongoing partnership between the two companies to further develop binder jet 3D printing for higher throughput and lower cost industrial 3D printed metal parts.

Nominations for the 2021 3D Printing Industry Awards are now open, have your say who is leading the industry now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows ExOne and Maxxwell Motors have successfully proved out a new concept for binder jet 3D printing a high-efficiency copper e-winding design. Photo via ExOne/Business Wire.