Every ACMA Convention in the recent past has had industry veteran Dr Pawan Goenka delivering his key growth pointers. This year too, he provided those and then some more.

“A lot has changed in the last 27 years in the Indian automotive industry. I would like to highlight three key points – we have come a long way in terms of quality today from where we were in the 1990s. How much we have been able to do product development in India, and thirdly, which is the most important, is how much has our supplier ecosystem has evolved. The Indian supplier base can rub shoulders with and compete with anyone in the world,” said Dr. Pawan Goenka, chairman, SCALE Committee and former MD and CEO, Mahindra & Mahindra, during his keynote address at the 61st ACMA Annual Convention today.

Dr Goenka acknowledged that India Auto Inc could never be global without its robust supplier base. Little knowing what 2020 had in store, he said he mentioned two years ago that “slowdown is not a bad thing. Last year, the topic was about shaping the new normal, and the hope was to come out of the Covid-19 situation.”

He complimented the industry for both managing and battling difficult times. “In the last 12 months when we thought we would be out of it, but the industry is battling supply chip shortage, commodity price increases, freight rate increase, geo-political issues and raw materials shortage. I hope we will be over the chip shortage shortly and not need to look back.”

Dr Goenka spoke about ‘Antifragile’ – when you have more to gain than lose in the presence of uncertainty (positive asymmetric payoff). “The word was introduced in 2012, but has not been used much. This is how I would like to see the auto component industry, which means every shock that is presented, we come out much stronger. I have seen this happening since last many years, especially during Covid-19.”

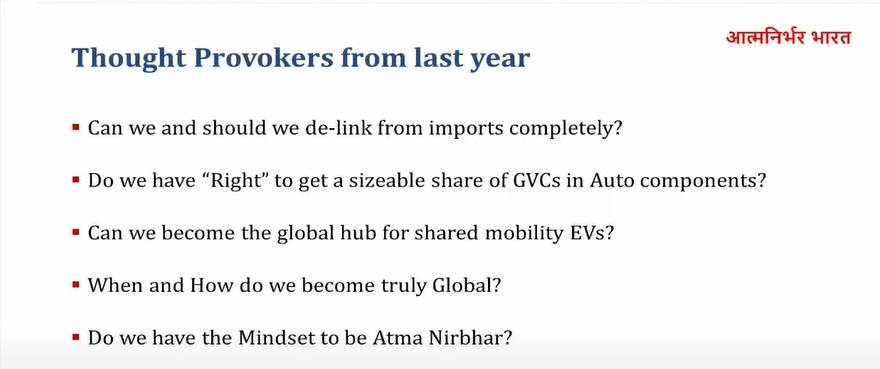

Five thought provokers

Five thought provokers

In his current role as the chairperson of the Steering Committee for Advancing Local value-add and Exports (SCALE), an initiative under the Ministry of Commerce & Industry, Dr Goenka said the government is looking to “make our manufacturing industries stronger.”

He said ‘Atmanirbhar Bharat’ is often misunderstood. It is not about banning imports, but it is about how we add value to goods that are being imported. Dr Goenka revisted the five thought provokers he had given last year.

Can India and should it de-link from imports completely?

“The answer is no. There is no way we can do everything all by ourselves. The auto industry in India is one of the shining examples of local value addition. The $100 billion automotive industry imports $25 billion worth of components. I don’t see no reason that we need to import components like glass, bearings, automatic transmission. We don’t make too many EV parts, sunroofs, which means there is significant room for localisation.”

Do we have the right to get a sizeable share of global value chains in autom components?

“While India has a robust component industry, we need to look at being part of the global value chain. What stops global suppliers from looking at India for export base? Why they have multiple plants in China but not in India? We need to find out the reason and understand why there is a hesitancy and solve it.”

Can India become the global hub for shared mobility EVs?

“From last year, the average monthly sales of EVs were around 200, it is now 500 in a year. After having 5% GST, which is less than 0.3% of our monthly sales. At this pace, we cannot achieve the aspirations that we have. We may lose out on the opportunity. There is opportunity for localising but cannot happen at the way we are moving today. Two things need to happen – firstly, the OEMs need to nurture local suppliers. While it is easy to import, they need to work closely with their suppliers to develop competencies here. Secondly, the suppliers have to invest before demand, because by the time demand comes, the suppliers may lose out on opportunity. This is both opportunity and concern, that we are not moving fast enough.”

When and how do we become truly global?

“There is only one Indian component supplier in the top 50 suppliers list globally. We need to think big . . . why can’t we target 5 suppliers in the top 50? It will require organic and inorganic growth.”

Do we have the mindset to be Atmanirbhar?

“It is all about inner grit. Be it working towards something challenging, the auto industry is a strong industry today. The OEMs and components have been working together for more than 30 years. In the near-term, the OEMs will need to pay a bit higher and the component suppliers might need to let go off profits for certain time. But this will pay off in the long run.”

Dr Goenka mentioned that the overall manufacturing industry in India looks up to the auto industry to lead the path to achieve self-reliance.

India Auto Inc needs to grow at 13% for the next 8 years

According to the SCALE committee’s findings, the three pillars for achieving Atmanirbhar Bharat are – increase exports, reduce imports and increase domestic consumption. This will require more vehicle sales and the auto industry needs to grow at 12-13% for the next 8 years.

Dr. Goenka suggested that OEMs and suppliers need to work together to make ‘Advance Technology Components’ in India. The country has right now the scale to fully manufacture with SKD and little CKD.

The EV industry has to aggregate inputs to achieve scale in India. “Our EV volumes are very small – if everyone goes to their own suppliers and develop their own technology, it will not be much of helpful. But if OEMs consolidate their demand and develop it together it will be beneficial. There is too much thrust being put on imports.”

He feels that Indian suppliers to invest in R&D and quality processes to win overseas business. “I am not talking about $10-20 million dollars from outside. If we want to big wins, we have to make big strides.”

Gunning for global suppliers business

Dr Goenka believes global suppliers should use India as part of their GVC (global value chain) and export from India. He said, “I request all large suppliers to start using India as their global supply base for their overseas plants. We are looking at incentives for the same under SCALE. At present, global OEMs have IPOs in India but the current sourcing does not justify the quality of suppliers (here). We are looking to address the issues of OEMs.

Addressing five disabilities

Dr. Goenka said there is a need to have concerned efforts to overcome 5 disabilities that are hurting overall exports from the country, not just specific to the auto industry.

“The Indian auto industry has the aspiration and component industry have the capability; in the last 12 months we have seen it already happening. The Indian automotive industry had a dream run from 2002 to 2015-16. We need to have the same kind of 2021. We have to charter a new path where quality and technology are ticket to ride. The government of India recognizes that the auto industry a strong pillar of economic growth,” concluded Dr. Goenka.

/news-national/dr-pawan-goenka-‘india’s-component-industry-can-compete-globally”-79908 Dr Pawan Goenka: ‘India’s component industry can compete globally.” Dr Pawan Goenka: ‘India’s component industry can compete globally.” https://www.autocarpro.in/Utils/ImageResizer.ashx?n=http://img.haymarketsac.in/autocarpro/36b9dfe7-c284-4524-a97b-20c2fef99920.jpg