Nissan Motor Co and Japan’s Waseda University today announced the start of testing in Japan of a jointly developed recycling process that efficiently recovers high-purity rare-earth compounds from electrified vehicle motor magnets. The testing is aimed at enabling practical application of the new process by the mid-2020s.

Most motors in electrified vehicles use neodymium magnets, which contain scarce rare-earth metals such as neodymium and dysprosium. Reducing the use of scarce rare earths is important not only because of the environmental impact of mining and refining, but also because the shifting balance of supply and demand leads to price fluctuations for both manufacturers and consumers.

Since 2010, Nissan has been working from the design stage to reduce the amount of heavy rare-earth elements (REEs) in motor magnets. In addition, Nissan is recycling REEs by removing magnets from motors that do not meet production standards and returning them to suppliers. Currently, multiple steps are involved, including manual disassembly and removal. Therefore, developing a simpler and more economical process is important to achieve increased recycling in the future.

Nissan has, since the past four years, been collaborating with Waseda University since the past four years. The Japanese institute has a strong track record of researching non-ferrous metal recycling and smelting. In March 2020 the collaboration successfully developed a pyrometallurgy process that does not require motor disassembly.

.jpg)

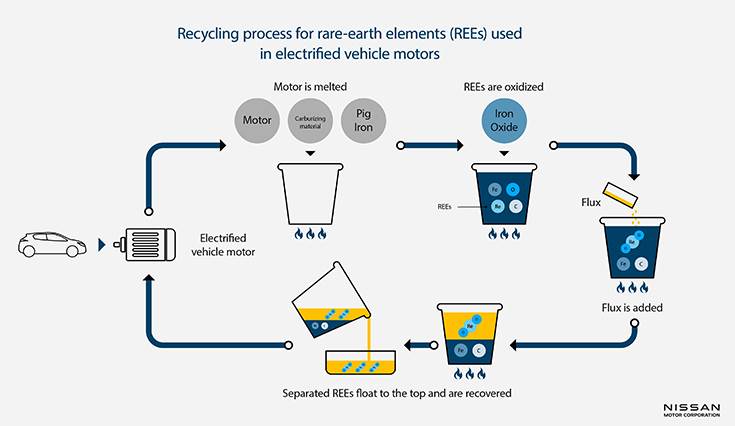

The process to recover 98% of REEs

– A carburising material and pig iron are added to the motor, which is then heated to at least 1,400 C and begins to melt.

– Iron oxide is added to oxidize the REEs in the molten mixture.

– A small amount of borate-based flux, which is capable of dissolving rare-earth oxides even at low temperatures and highly efficiently recovering REEs, is added to the molten mixture.

– The molten mixture separates into two liquid layers, with the molten oxide layer(slag) that contains the REEs floating to the top, and the higher density iron-carbon(Fe-C) alloy layer sinking to the bottom.

– The REEs are then recovered from the slag.

<>

Testing has shown that this process can recover 98% of the motors’ REEs. This method also reduces the recovery process and work time by approximately 50% compared to the current method because there is no need to demagnetize the magnets, nor remove and disassemble them.

Going forward, Waseda and Nissan will continue their large-scale facility testing with the aim of developing practical application, and Nissan will collect motors from electrified vehicles that are being recycled and continue to develop its recycling system.

/news-international/nissan-and-waseda-university’s-recycling-tech-helps-recover-rareearth-elements-from-ev-motors-79969 Nissan and Waseda University’s recycling tech helps recover rare-earth elements from EV motors Nissan and Waseda University’s recycling tech helps recover rare-earth elements from EV motors https://www.autocarpro.in/Utils/ImageResizer.ashx?n=http://img.haymarketsac.in/autocarpro/417a7853-7d07-4cc0-892a-209bf6909215.jpg