Chinese companies began to threaten the U.S. market, which is home to three Korean battery companies, LG Energy Solution, Samsung SDI, and SK On.

The three American automakers, General Motors (GM), Ford, and Stellantis, have adopted Korean-made electric vehicle batteries for local sales. However, this trend has been threatened recently. Chinese companies are aggressively targeting small and medium-sized automakers with cheap lithium iron phosphate (LFP) batteries. Due to the trade conflict between the U.S. and China, Korean products have a selective advantage; however, China is aiming for a niche.

Gotion, the fourth largest producer of electric vehicle batteries in China, announced that it has recently signed an LFP battery supply contract with an automaker listed on the New York Stock Exchange.

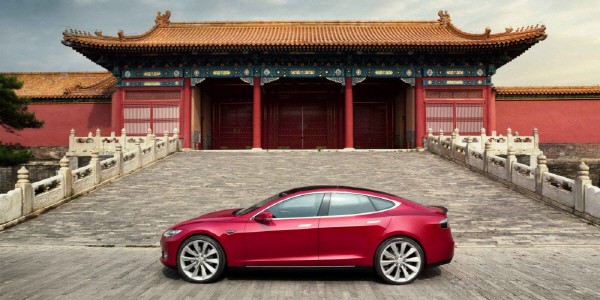

Gotion plans to supply 200GWh batteries from 2023 to 2028, and build a local battery factory. Although Gotion did not mention the name of the American company, the industry assumes that Tesla is the most likely candidate. This is because, among North American electric vehicle makers, Tesla products are currently the only vehicles equipped with LFP batteries.

If Gotion builds a local battery production plant, it will be the first Chinese company to build a plant in the U.S. Most of the companies that have selected Chinese batteries in the U.S. for domestic use have been only small manufacturers so far.

CATL recently signed a two-year 175MWh supply contract with Lightning e-Motors, an American electric commercial vehicle maker. It previously signed a supply contract with electric commercial vehicle makers Phoenix Motor Cars and Electric Last Mile Solutions (ELMS), but the supply amount was hundreds of MWh.

The only contracts for Chinese companies GWh-range export to the U.S. were CATL and Fisker, supplying more than 15 GWh of batteries for three years.

This is quite insignificant amount compared to the supply of batteries from the three domestic battery companies, which are hundreds or tens of gigawatts.

An official from the battery industry said, “Unlike Europe, the U.S. battery market has very little adoption of Chinese batteries. The situation is advantageous for domestic products due to the trade conflict between the U.S. and China, but we cannot disregard the LFP battery made in China, which has quite attractive price tag.”

The three domestic companies are currently building large-scale joint ventures or their own factories in the United States. By 2025, the battery production capacity that domestic companies will produce in the U.S. is 330 GWh, which is more than 400 GWh when including the capacity of existing local factories.

LG Energy Solution has decided to establish a joint plant with GM with an annual production capacity of 70 GWh by 2025, and establish a 40 GWh joint venture with Stellantis. SK on also confirmed the establishment of a joint factory with Ford. It will build a joint battery plant with a total annual capacity of 129GWh in two locations in the U.S..

Samsung SDI also recently confirmed the establishment of a joint venture with Stellantis, and is looking for a plant site. The plant will be operated with an annual capacity of 23GWh from 2025, and will be expanded to 40GWh in the future.

[Table] Plans to build a U.S. battery joint venture plant by three domestic battery companies (data industry)

By Staff Reporter Tae-jun Park (gaius@etnews.com)