The Camozzi Group, parent firm of large-format 3D printer manufacturer Ingersoll Machine Tools, has entered into a partnership with Alfa Romeo F1 team ORLEN.

Set to take on advertorial, technical and sporting dimensions, the deal will see the Camozzi Group use its production expertise to aid the work of both the Alfa Romeo F1 team, and its sister firm Sauber Technologies. Having signed the agreement, the former is now said to be relishing the opportunity to “rise to the technological challenges” of Formula 1, while showcasing its products around the world.

“The thought of becoming a partner with the Alfa Romeo F1 Team ORLEN is extremely attractive not only because of the racing aspects but also because of Sauber Technologies’ commitment to innovation and its application throughout the business world,” said Lodovico Camozzi, CEO of the Camozzi Group. “We are thrilled to have this opportunity to race with them and develop new projects together.”

Camozzi’s racing pedigree

Since it was founded in 1964, the Camozzi Group has established itself as a leader in the field of industrial automation, while occasionally dipping its toe into the world of motorsport as well. Having first entered Formula 1 with the Arrows team in 1985, the firm went on to join forces with McLaren over a five-year stretch, that saw the team win the constructors’ title, and Mika Hakkinen claim two drivers’ crowns.

Since then, the company has departed Formula 1, instead focusing its efforts on expanding its manufacturing capabilities via a string of acquisitions, including Ingersoll Machine Tools, which it bought in 2003. Now operating as part of the Camozzi Machine Tools division, the firm specializes in building advanced production systems, with both additive and subtractive manufacturing capabilities.

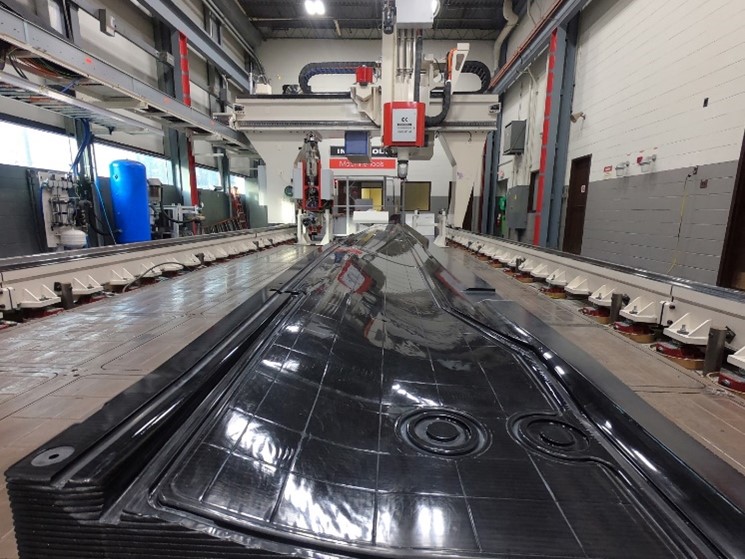

Among the machines Ingersoll Machine Tools has developed, including the MasterMill, PowerMill, SuperProfiler and Mongoose, it’s best known in the 3D printing industry for its MasterPrint units. Available in three and five-axes variations, as well as with robotic arms, the large-format system is able to over-print, reinforce parts with carbon fiber and finish them thanks to its in-built milling functionality.

In the past, the MasterPrint has been deployed in the manufacture of a 22 foot-long vacuum trim tool – a mold used for the production of Bell helicopter rotor blades, and although it’s unclear how exactly Ingersoll Machine Tools intends to work with the Alfa Romeo F1 team moving forwards, their de facto partnership raises the possibility that its 3D printing technologies will now be used within Formula 1 R&D.

Announcing a Formula 1 return

With the unveiling of its partnership with the Alfa Romeo F1 team, the Camozzi Group has effectively announced its return to the world of Formula 1. In its new role as a technological partner, the firm is set to not only work with the race team on engineering issues, but harness the synergies it shares with Sauber Technologies, the Sauber Group’s entity dedicated to translating its knowhow into the wider world.

As a first step to achieving this, the companies’ deal includes plans to create a joint R&D lab, involving Camozzi’s Research Centre (CRC) in Milan, Italy, and the Sauber Technologies HQ in Hinwil, Switzerland. Given the known 3D printing capabilities of both these facilities, it’s highly-likely that the firms’ newly-established talent and knowledge exchange program will zoom in on the technology’s racing potential.

Speaking about the deal ahead of the upcoming Formula 1 season, which will see the introduction of a completely new-generation of cars, Frédéric Vasseur, Team Principal of Alfa Romeo F1 team ORLEN, explained how its partnership with the Camozzi Group is set to not only aid its racing performance, but that of the wider Sauber Group as well.

“There are many potential crossovers between their work and that of Sauber Technologies, a company within the Sauber Group,” adds Vasseur. “The Camozzi Group is a natural fit for us: they have a long history of excellence in Formula One and they understand our requirements and need for precision and excellence.”

“Synergies are what the joint projects we are going to carry out with the Camozzi Group will be about, as well as promoting a new generation of talented engineers and researchers.”

Moving up the grid with 3D printing

In the world of Formula 1, split seconds can mean the difference between success and failure, and teams are increasingly turning to 3D printing in search of a vital edge over the competition. The Alfa Romeo F1 team, for instance, is also known to use Additive Industries’ technology in the build of its cars, and when last year’s challenger was rolled out, it was said to feature 304 3D printed elements.

Similarly, McLaren Racing has been using additive manufacturing trackside for tooling and prototyping applications since at least 2017, and its partnership with Stratasys is said to have continued beyond their initially-agreed collaboration.

Fellow British Formula 1 team Williams Racing, meanwhile, has established a partnership with Nexa3D, with the aim of producing custom polymer parts specifically for motorsport applications. When the deal was signed, the team outlined plans to use the high-speed NXE400 3D printer to manufacture functional wind tunnel parts, as a means of honing the aerodynamic properties of its cars.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a render of the Alfa Romeo F1 Team ORLEN 2022 racing car. Image via Alfa Romeo F1 Team ORLEN.