During a livestream out of Japan this morning, Nissan Motor Company unveiled plans to bring laminated solid-state batteries to market by 2028, beginning with a prototype production facility. The decision is part of Nissan’s “Ambition 2030” strategy, which will now include plans to launch an EV powered by solid-state batteries in 2028.

Nissan Motor Corporation ($NSANY) has been manufacturing cars in Japan since the 1930s and has become globally recognized behind brands like Infiniti and Datsun, in addition to its main marque.

The company was one of the early promoters of electric vehicles with its Nissan LEAF, which debuted in 2010, currently maintaining a reign as one of the longest-running electric models in the US. Despite that fact, the LEAF sits as Nissan’s lone BEV offering for sale, at least until the new Ariya arrives.

Last summer, Nissan joined the UN’s “Race to Zero” campaign aiming to be 100% electric by the early 2030s with a strategy that includes the launch of 15 BEVs over the next eight years. Nissan called its own strategy for electrification “Ambition 2030,” which it outlined last fall.

At the time, we learned of Nissan’s plans for four new EV concepts, plus an investment of $17 billion in electrified technologies over the course of five years, including funds allocated toward R&D for solid-state batteries.

Following the latest news from the automaker, it will begin pilot production of solid-state batteries in Japan, and we might see a Nissan EV powered by SSBs in 2028.

Nissan to develop solid-state batteries for its future EVs

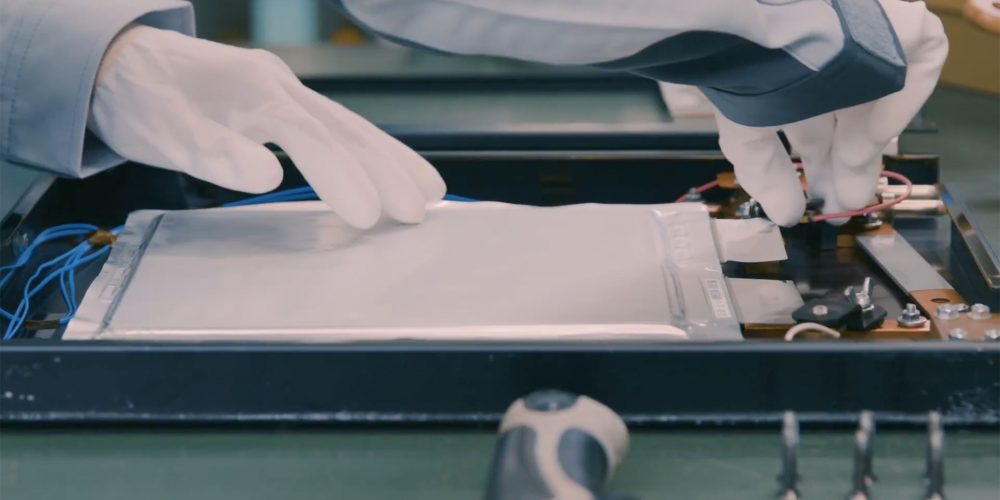

During a live presentation out of Yokohama, Japan, the automaker shared news of its prototype production facility for laminated solid-state batteries located within the Nissan Research Center in Kanagawa Prefecture.

According to the coinciding press release, the materials, design, and manufacturing processes for prototype production of the solid-state batteries will be studied at the new prototype production facility.

The data gathered will then be used to establish a pilot production line at Nissan’s Yokohama Plant in 2024, with the eventual goal of scaled manufacturing of solid-state batteries in-house by 2028.

By this point in the future, Nissan believes its solid-state batteries can be reduced to $75 per kWh and down to $65 per kWh after 2028, putting EVs at cost parity with ICE competitors. Kunio Nakaguro, executive vice president in charge of R&D, spoke to the announcement:

Nissan has been a leader in electrification technology through a wide range of R&D activities, from molecular-level battery material research to the development of safe, high-performance EVs. Our initiatives even include city development using EVs as storage batteries. The knowledge gained from our experience supports the development of all-solid-state batteries and we’ve accumulated important elemental technologies. Going forward, our R&D and manufacturing divisions will continue to work together to utilize this prototype production facility and accelerate the practical application of all-solid-state batteries.

As part of its “Ambition 2030” strategy, Nissan believes it can deliver an EV powered by these prospective solid-state batteries in 2028 and expects the cells to help it remain competitive in multiple vehicle segments, including pickup trucks.

That’s not all either; Nissan is taking a multi-faceted approach to expanded electrification, including its “e-Power” hybrids and bi-directional charging. Check out the automaker’s latest video presentation below:

FTC: We use income earning auto affiliate links. More.

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.