But this is not the way to go for Bosch. Seeo is to be sold, while the Lithium Energy and Power GmbH & Co. KG (LEAP) joint venture dissolved.

Bosch’s reasoning is too high economic risks as initial investment alone would be some 20 billion euros to build a 200 GWh production facility for some 20% market share.

Operating costs run into the billions (three-quarters of the manufacturing cost would be cost of materials). Bosch just doesn’t feel secure with this investment.

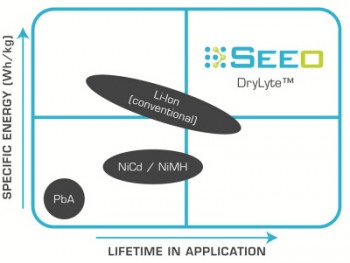

Seeo DryLyte

“Regardless of the decision that has now been made, Bosch sees huge potential in solid-state technology. “Technically speaking, we’ve made excellent progress in our development work. Solid-state technology is the way forward,” Pillin adds. The decision to continue buying in cells in the future is the result of a lengthy economic assessment, in which it became clear that investing in the commercialization of cell technologies – whether improved existing technologies and future ones – is too risky. For a competitive, market-relevant cell manufacturing operation, calculations showed that the initial investment alone would be some 20 billion euros. This sum would allow the company to set up manufacturing capacity of approximately 200 gigawatt-hours, equivalent to a 20 percent market share, and thus a leading position in the market.

In addition to this initial investment, there would be operating costs running into billions, and three-quarters of the manufacturing cost would be cost of materials. This would therefore leave only a narrow scope for creating and exploiting competitive advantages. Given dynamic external market factors that can only be predicted with difficulty, it is unclear whether this investment would pay off for Bosch, and when. In the interest of the company as a whole, therefore, such a risky investment cannot be justified.”

Bosch will stick with battery systems, purchasing battery cells from others and supplying packs to vehicle manufacturers.

Aim is to lead electromobility mass market from 2020

Bosch strategy: systems expertise, energy efficiency, and standardization

In-house cell manufacturing is not decisive for success in electromobility

Center of competence secures cell expertise

Bosch supplies electrical powertrains in all vehicle segments, from bicycles to trucks

Find out more about electromobility at Bosch in the webspecial

Stuttgart, Germany – Bosch aims to lead the mass market for electromobility that will emerge after 2020. In this endeavor, it is relying on its systems expertise and the development and manufacture of key components of the electrical powertrain, such as the electric motor, power electronics, and battery systems. The company will continue to buy in the cells needed to make these battery systems. For economic reasons, Bosch has decided not to set up cell manufacturing operations of its own. “For Bosch, it’s important to have a technical understanding of cells. We don’t have to make them ourselves,” says Dr. Rolf Bulander, member of the board of management of Robert Bosch GmbH and chairman of the Mobility Solutions business sector.

Established automakers are currently extending their vehicle ranges to include many electrified models. At the same time, start-ups are entering the market with new electromobility concepts. Bosch’s electromobility strategy takes account of these dynamic market developments. Its objective is to make electric driving more viable and mass-marketable. The strategy Bosch is pursuing involves increasing electric vehicles’ energy efficiency, using systems expertise to intelligently link all the components of the powertrain, and using standardized components to make electromobility scalable and affordable. Beyond the vehicles themselves, Bosch is developing solutions for the recharging infrastructure. Using web-based services, the recently premiered “system!e” will considerably enhance the viability of electric driving.

Expansion of battery business – a center of competence for technology development

Bosch will continue to work with cell suppliers to design cells for hybrid- and electric-vehicle batteries, and buy these cells from them. For this reason, the company is disbanding its research into current and future cell technologies, whose brief was to assess the feasibility of in-house cell production. The Lithium Energy and Power GmbH & Co. KG (LEAP) joint venture for lithium-ion technology will be dissolved. The subsidiary Seeo, which researches into solid-state technology, is to be sold. In a center of competence, Bosch will continue to add to the comprehensive battery-cell expertise it has built up over recent years. As was occasionally the case in the past, several hundred associates will continue to work on battery systems. They will develop battery-management systems and 48-volt battery systems, and draw up the specifications for cells. “Even now, Bosch is capable of integrating individual components into complete systems. We make highly efficient 48-volt battery systems and develop attractive battery-management systems,” says Dr. Mathias Pillin, who is responsible for electromobility activities at Bosch. The technology development work at the center of competence will benefit not only automotive applications but also products from other parts of Bosch, such as household appliances and power tools.

Technological potential exists, but economic risks are high

Regardless of the decision that has now been made, Bosch sees huge potential in solid-state technology. “Technically speaking, we’ve made excellent progress in our development work. Solid-state technology is the way forward,” Pillin adds. The decision to continue buying in cells in the future is the result of a lengthy economic assessment, in which it became clear that investing in the commercialization of cell technologies – whether improved existing technologies and future ones – is too risky. For a competitive, market-relevant cell manufacturing operation, calculations showed that the initial investment alone would be some 20 billion euros. This sum would allow the company to set up manufacturing capacity of approximately 200 gigawatt-hours, equivalent to a 20 percent market share, and thus a leading position in the market.

In addition to this initial investment, there would be operating costs running into billions, and three-quarters of the manufacturing cost would be cost of materials. This would therefore leave only a narrow scope for creating and exploiting competitive advantages. Given dynamic external market factors that can only be predicted with difficulty, it is unclear whether this investment would pay off for Bosch, and when. In the interest of the company as a whole, therefore, such a risky investment cannot be justified.

Bosch expertise relates to the entire electromobility ecosystem

It is equally clear that is above all understanding of battery cells, not in-house manufacturing of the cells themselves, that is decisive for business success in electromobility. Even without cell manufacturing operations, Bosch is well positioned in electromobility. “We want to be the go-to partner for electric driving. We are already a leader in the powertrain field – and we will be in the future as well,” Bulander says. Bosch electrical powertrain components already feature in more than 800,000 vehicles around the world. The supplier of technology and services has carried out more than 30 production-related projects together with established automakers and start-ups around the world. It is the market leader in China, the world’s biggest and fastest-growing electric-vehicle market. The company’s portfolio stretches from power electronics, to 48-volt mild hybrid batteries and battery-management systems, to electric motors and electric axle systems. Bosch technology can be found in practically every class of vehicle: it develops and manufactures components for electric bicycles, scooters, passenger cars, and commercial vehicles. Bulander adds: “In the electromobility business, no other automotive supplier is as broadly diversified as Bosch.” Bosch is partnering with various automakers to give drivers of electric vehicles access to some 17,400 charge spots in five European countries – with the help of charging apps, for example. “Bosch’s expertise covers the entire electromobility ecosystem – from proven components for electrified applications to digital connection with the charging infrastructure,” Bulander says.