3D printer manufacturer Stratasys has been named an Official 3D Printing Partner of Toyota Racing Development (TRD), the in-house tuning division of automotive firm Toyota.

Already, in its new role, Stratasys has helped TRD develop several end-use 3D printed parts for the Toyota GR86, a sub-£30,000 production vehicle that’s set to be raced in the single-make GR Cup series. Using its partner’s technologies, TRD says it has managed to ramp up the R&D of these parts, while significantly reducing their cost of production.

“Additive manufacturing has allowed us to quickly iterate, design and create parts for our race vehicles, in a way that would have been far more expensive or labor intensive through traditional manufacturing methods,” explains David Wilson, President of TRD. “By partnering with Stratasys, we are able to advance our manufacturing practices beyond what is currently possible, and really harness the possibilities of additive manufacturing for production parts.”

Toyota’s AM exploits: a brief history

Headquartered in the Japanese prefecture of Aichi, Toyota is a multinational car manufacturer that, having sold over 9.6 million vehicles in 2021, remains one of the largest in the world. As you’d expect, this figure incorporates the sales of numerous different makes and models, many of which will have been made via traditional production processes.

However, in recent years, Toyota has also increasingly shown an interest in 3D printing, not just as a means of prototyping, but manufacturing end-use parts for its production cars. As long ago as 2015, the company worked with Materialise to develop an ultra-lightweight 3D printed car seat, before unveiling a new, shape-shifting ‘uBox’ car concept later that year, complete with customizable printed trim.

These innovations were followed by further investments in research, including a partnership with DSM, in which Toyota co-developed Somos Taurus, a material with an automotive-friendly heat deflection temperature of 95°C. The firm has also had the 3D printing wing at the University of Waterloo named after it, in the wake of a $2.1 million (CAD) donation it made to the institution, to advance its R&D.

Since then, Toyota has (from what it’s said publicly) appeared to expand its 3D printing adoption further, by beginning to integrate the technology into its race cars. At its Toyota Motorsport division, for instance, the company has not just unveiled plans to develop a new lightweight automotive material, but partnered with 3D Systems to create advanced technologies with high-end racing applications.

Gearing up for the GR Cup

Toyota’s latest forray into the world of additive manufacturing has seen its TRD division naming Stratasys as its new Official 3D Printing Partner. Over the last 43 years, TRD has won championships in motorsports ranging from NASCAR’s Cup Series to NHRA Funny Car drag racing, establishing it as a trusted tuning body with significant motorsport expertise.

As well as working on improving the performance of Toyota’s street cars, the organization is also responsible for supporting its motor racing exploits, hence it has been tasked with helping rebuild the GR86. Powered by a 2.4 liter boxer engine, the 231 bhp vehicle is being tuned by TRD for the GR Cup, a 14-race amateur, and affordability-focused race series, that’s set to launch next year in the US.

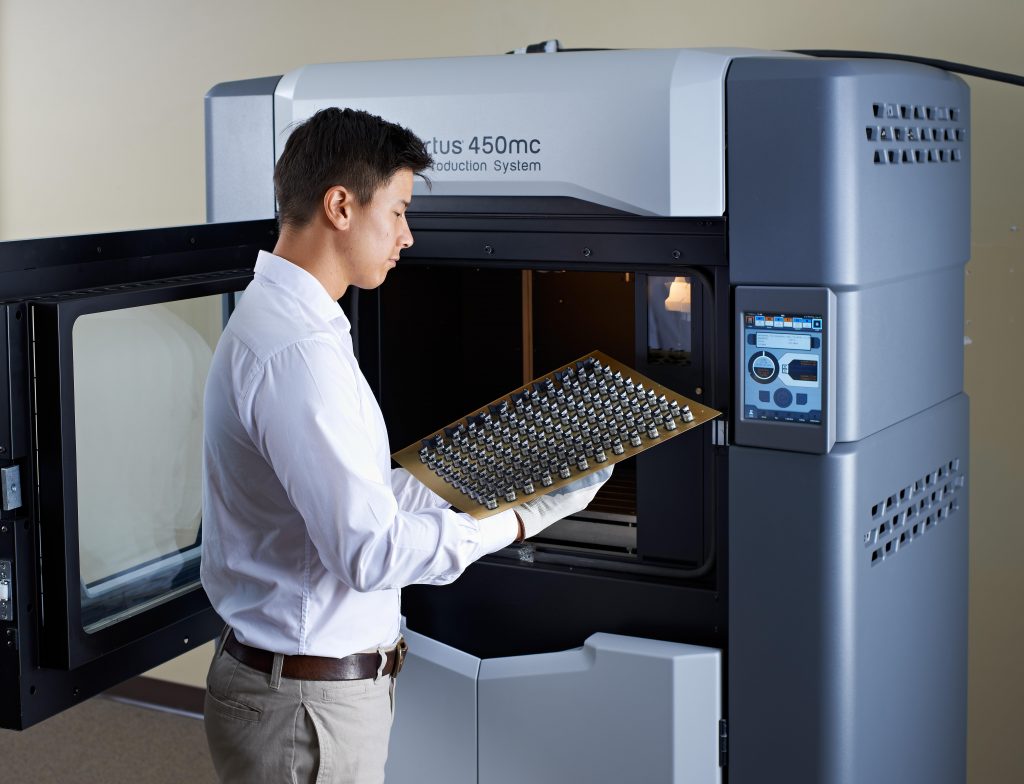

In order to prototype and produce the modifications needed, including a Nylon 12CF GR86 hood vent, plus various other parts for its vehicle portfolio, the Toyota team has turned to the Fortus 450mc, F370, and F370CR 3D printers at Stratasys’ facilities in North Carolina and California, where they’ll be made before being shipped.

While TRD is a long-term customer of Stratasys Direct, it says it now also plans to take advantage of its partners’ services to produce PA11 clamps for the GR86, which will be debuted, alongside various other parts, at the first GR Cup race in 2023.

“This new partnership represents a significant moment in the evolution of additive manufacturing for high-performance automotive racing applications,” adds Pat Carey, Senior Vice President of Strategic Partnerships at Stratasys. “We will partner with TRD to support their efforts as they further adopt, prove out and integrate additive manufacturing into their production as a prototyping, tooling and end-use parts solution across the GR86 and TRD custom parts as well.”

3D printing’s end-use motorsport market

As impressive as TRD’s racing resume is, it’s not the only automotive racing team to be increasing its adoption of 3D printing for end-use components. Late last month, it was revealed that Stratasys’ technologies would also be used to 3D print parts of NASCAR’s Next Gen race cars, including the vehicles’ ventilation systems.

Over in MotoGP, meanwhile, Ducati Lenovo has begun working with Roboze to 3D print fairing and bike shielding for its 2022 challenger, as part of a new technical partnership. By producing these aero-parts using additive manufacturing, the team is said to have realized both quality and lead time improvements.

Even at the pinnacle of single-seater motor racing, in Formula 1, teams up and down the grid continue to adopt the technology. Due to the sport’s competitive nature, its engineers can be reticent to share their latest innovations, but in an interview with 3D Printing Industry, Pat Warner recently revealed that up to 70% of the body on the BWT Alpine F1 car is prototyped via 3D printing.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Toyota’s GR Cup-spec GR86 race car. Image via Toyota.