Floridian race outfit Brumos Racing has unveiled plans to run a 3D printing-optimized Porsche at this year’s Pikes Peak International Hill Climb.

Composite tooling manufacturer Airtech Advanced Materials Group has 3D printed molds and end-use parts for the team’s GT2 RS Clubsport, which is set to take part in the 100th running of the event on June 26, 2022. These upgrades, alongside those produced via a slew of other advanced technologies, are expected to make Brumos Racing’s challenger lighter, more aerodynamic and faster up the course.

Airtech’s Print-Tech portfolio

While Airtech has established itself as one of the world’s largest vacuum bagging and composite tooling material developers, it’s better known in the 3D printing industry for its Print-Tech offering. Built on the back of nearly fifty years’ extrusion experience, the firm’s service allows users to order large-scale 3D printed composite tooling parts, such as trim fixtures, holding fixtures and layup molds.

Using its fleet of 40ft x 10ft Fused Deposition Modeling (FDM) 3D printers, Airtech claims it’s possible to bring tooling from conception to the shop floor significantly faster than conventional methods allow. Thanks to the high temperature stability exhibited by its Dahltram tooling resins, the firm also says its services can meet thermally-demanding use cases, like autoclave and oven mold production.

In order to expand the reach of its 3D printing offering, the firm has not only bought a Large Scale Additive Manufacturing system from the Thermwood Corporation, but made its Dahltram materials compatible with Titan Robotics’ machines.

When it comes to producing customized tooling, Airtech says that this “continuous product development” delivers cost and performance advantages for clients. In particular, the company suggests that its high-accuracy, short lead time offering is a “game changer” for those automotive manufacturers engaged in the drilling, composite molding, metal bonding or transparency forming of large vehicle parts.

Preparing a Porsche for the Peak

At 14,115 feet, Pikes Peak is simultaneously the tallest summit in the Southern Front Range of the Rocky Mountains, and home to a legendary invitational event. The peak’s grueling course has become a staple in the automotive calendar, and a proving ground for vehicle manufacturers the world over. Having run annually since 1916, stopping only for the World Wars, it’s also the second oldest race in the US.

With the iconic hill climb now approaching its 100th running, Brumos Racing has decided to enter a 700 hp Porsche, but in order to truly make it Pikes Peak-ready, the team has sought to enhance its performance. To make this possible, the outfit reached out to new Technical Partner Airtech, who in turn, teamed up with BBi Autosport to develop custom 3D printed mold tooling for the vehicle’s upgrades.

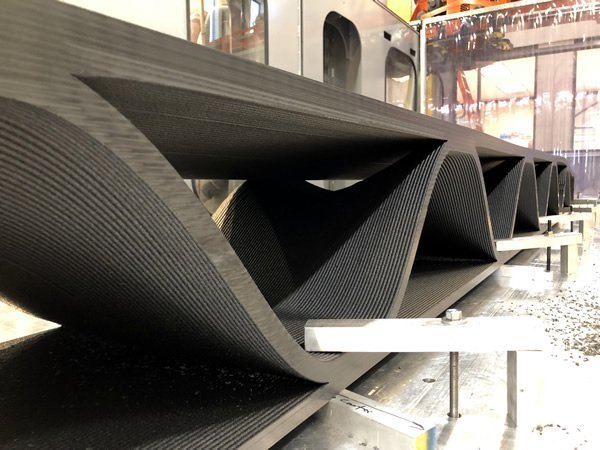

Made from Airtech’s Dahltram resin via its in-house 3D printing service, these molds are said to have yielded polymer-infused carbon fiber parts, which aren’t just lighter than standard, but provide the team’s Porsche with ‘aerodynamic enhancements.’

According to Airtech, producing the parts via its technologies has also allowed Brumos Racing to improve the efficiency and flexibility of its design process, while ‘drastically’ reducing the development time of its car. The upgraded vehicle is set to debut at the 100th Pikes Peak Hill Climb, where it’ll be driven by veteran racer David Donohue, complete with the team’s distinctive striped livery.

Mold additive manufacturing at scale

Outside industrial circles, molds may seem like a low-importance part of the manufacturing process, but their accuracy and durability can be vital to the quality of resulting products. Alongside Airtech, Massivit 3D is also seeking to normalize the 3D printing of these molds, only it doesn’t just offer to create them for clients, it sells fully-fledged production units powered by its Cast-In-Motion technology.

Utilizing another large-format machine, in this case developed by Ingersoll Machine Tools, researchers at University of Maine have previously set out to create a bio-based wind turbine blade mold. By introducing 100% recyclable feedstock into their Cellulose Nanofiber (CNF) 3D printing process, the UMaine team believe that it’s possible to cut the costs of producing such large-format parts by up to 50%.

Elsewhere, the Thermwood Corporation has similarly partnered with aviation firm Bell to 3D print a 20-foot helicopter blade mold, before later displaying it at Rapid+TCT 2022. Said to be the largest autoclave capable-tool of its kind, the temperature and elevation pressure-resistant equipment has specifically been designed to enable the development of resilient chopper components.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Brumos Racing’s Porsche GT2 RS Clubsport race car. Photo via Airtech.