Ssangyong Motor will install China’s BYD batteries in their ‘Torres Electric Vehicle (tentative name)’ which will be released next year. Kia also recently formalized the adoption of Chinese CATL batteries for its new Niro EV. They have begun adopting Chinese batteries onto electric vehicles for domestic sales, not just exclusively for local sales in China.

Ssangyong Motor will begin selling its new Torres-based electric vehicle in Europe and South Korea starting from the second half of next year. The vehicle will be equipped with a ‘blade battery’ based on lithium iron phosphate (LFP), the latest battery from China’s BYD. Following Kia’s ‘Niro EV’, it is the second instance of installing a Chinese-made battery in a vehicle sold in South Korea. Kia installed a 65kW h-class ternary system (NCM) battery from China’s CATL in its new Niro EV, which was released earlier this month.

The batteries of the two electric vehicle models are characterized by increased energy density with pack design technology as well as cells. Both CATL and BYD greatly improved space utilization by applying square form factor design technology without module processes. This is a new technology that the three domestic battery companies have not yet secured.

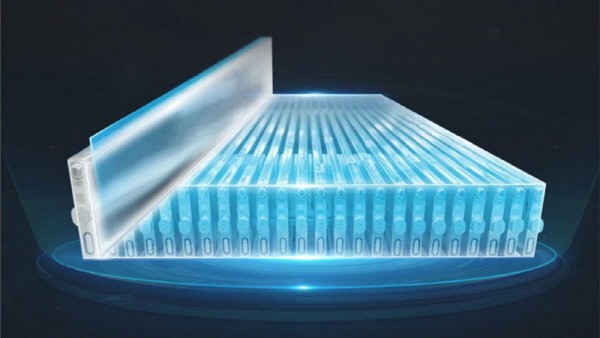

BYD’s blade battery single cells are arranged in a line-up and inserted into a battery pack. BYD explains that the space utilization of the battery pack is about 50% higher than that of conventional lithium iron phosphate block batteries.

Although they are LFP batteries that have lower energy density than ternary-based (NCM) batteries, the main active cathode material of domestic companies, they have been supplemented by increasing the energy density of the pack. LFP is cheaper than NCM, but has lower energy density. BYD’s pack technology compensates for its shortcomings while maintaining its strengths.

The Niro EV also applied CATL’s CTP (Cell to Pack) technology, which improved the space utilization of the battery pack. This battery is a lithium-ion high-nickel ternary (NCM 8:1:1)-based module-free structure. It is expected that it can contain 10% more electric energy than the battery systems of the three domestic companies, as it is manufactured with NCM with high energy density.

An industry official said, “Since Ssangyong Motor has cut off deals with domestic battery makers due to exceeding contract volume, China’s BYD battery was chosen as the next best solution, giving it an advantage in price competitiveness and performance,” and, “The three domestic battery companies have not yet commercialized a battery pack design technology that improves space utilization.”

By Staff Reporter Tae-jun Park gaius@etnews.com