For the past ten years, Dinesh Ramanathan has been working to see how best he can use gallium nitride (GaN) in power conversion systems, the devices that do AC to DC, DC to DC, and DC to AC conversions. If one can make the systems smaller and more efficient, they can have a substantial impact in areas like gaming laptop chargers, data centres and electric vehicles.

Traditionally, silicon was used for these systems. But silicon has reached its limits. So researchers are trying compound semiconductors. Some use silicon carbide. Some use a silicon wafer and grow GaN crystals on it. Ramanathan has succeeded where many others have failed – he’s growing GaN crystals on a GaN wafer. This GaNon-GaN technology, he says, can withstand very high voltages, and can switch those voltages at very high frequencies. “When you run it at very high switching frequencies, you shrink the size of the power supplies (capacitors, inductors) and also improve their efficiency dramatically,” he says.

He holds up a traditional 87-watt charger and another 240-watt one that his company, NexGen Power Systems, has developed. The NexGen charger is slightly smaller, and significantly thinner. “Our 240-watt power supply for a gaming laptop application is 61% smaller and half the weight of what’s available in the market today,” says Ramanathan, a BITS Pilani graduate who went on to do a PhD in computer science in the US, and who has been in the sem- iconductor space for nearly 27 years, including with Synopsys and Cypress Semiconductor.

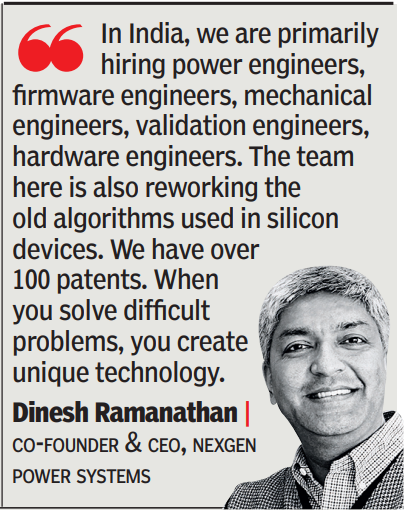

NexGen, founded in 2017, makes the semiconductor in its own fab in New York. But all the design and engineering of its power electronics products are done by its centre in Bengaluru, and the final product is assembled by a contract manufacturer in Chennai and shipped to the world.

Ganesh Guruswamy, who was senior VP at SanDisk and who joined NexGen in January as chief systems officer, says electric vehicles (EVs) today use silicon carbide. “But silicon carbide cannot switch more than 300-khz. And that makes the system very big and heavy. Our technology switches at much higher frequencies, allowing us to shrink the capacitors, inductors and make the system very compact. We are giving more power in the same footprint, and the electronics are lighter, so the car can go further,” he says.

Customers in gaming laptops and lighting are sampling the product. Commercial production is expected to start later this year.

Go to Source