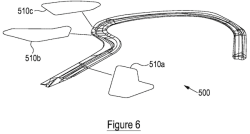

We have just been granted a patent for manufacturing carbon fibre components through a braiding process that we have developed here at Riversimple. This allows us to make hollow components, of varying cross-section with bends in different axes, for elements of the structure such as the ring around the door.

Although braiding is not new in its own right – it is how socks are woven – the particular novelty of this process is that we can make a tubular component with a cross-section that includes a negative feature, necessary for locating the door seal. This semi-automated process has no wastage and ensures conformity of production – the guarantee that each chassis is identical, so will perform the same in crash tests.

Although braiding is not new in its own right – it is how socks are woven – the particular novelty of this process is that we can make a tubular component with a cross-section that includes a negative feature, necessary for locating the door seal. This semi-automated process has no wastage and ensures conformity of production – the guarantee that each chassis is identical, so will perform the same in crash tests.

Incidentally, we are also joint patentees on the core motor patents of YASA Ltd, which was acquired by Mercedes in 2021. The original YASA motors were developed as part of our LIFECar project with Morgan, our first fuel cell car shown at Geneva in 2008.