Japan’s Komatsu Ltd and Toyota Motor Corporation have announced the launch of a joint project to develop an Autonomous Light Vehicle (ALV) that will run on Komatsu’s Autonomous Haulage System (AHS).

To realise further safety and productivity improvements in mines by running autonomous haul trucks and automated ALV controlled by AHS, Komatsu and Toyota are launching an effort to jointly develop new technologies. Both companies are currently testing a concept ALV at their proving grounds, and plan to have a proof of concept at a customer site by around January 2024.

While minerals and energy resources are essential for industries, autonomy offers the opportunity to remove people from harm’s way and enhance safety. Along with doing the job of sourcing critical minerals despite the ongoing challenge of labour shortages, ALVs can also provide additional safety measures at mine sites on which multiple pieces of equipment are operated, in an effort to reduce accidents due to human error.

Since the launch of the world’s first commercial application of an AHS in 2008, Komatsu has established proven performance in various mine environments and has earned a reputation for safety and productivity. Currently, when AHS-enabled autonomous haul trucks and manual light vehicles used for maintenance or transport are running on haulage roads at the same time, autonomous haul trucks may decrease their speed or stop when passing light vehicles to avoid possible collisions caused by human error. On the other hand, customer demand for improved productivity in mine operations when it comes to autonomous haul truck operating efficiency remains an issue.

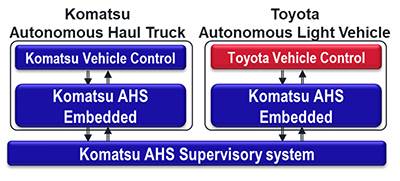

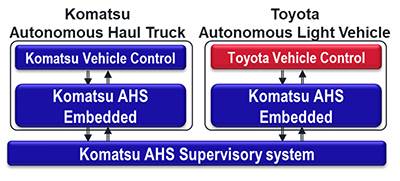

Now, in an effort to solve those issues quickly, Komatsu and Toyota have come together to accelerate autonomy in mines. Komatsu will develop a new management program for ALVs on its AHS supervisory system, and Toyota will develop ALVs running automatically under AHS control.

Key focus areas of the joint ALV project

By operating Komatsu’s autonomous haul trucks and Toyota’s ALVs in mine sites utilising a common AHS, the following safety and productivity improvements will be realised across the mining operation:

– ALVs operating safely along haul roads.

– Prevent accidental contact caused by driver, as may happen with existing manual light vehicles.

– Minimise speed reductions or brief stops of autonomous haul trucks while passing light vehicles on a haul road.

– Toyota’s ALV autonomous operation accelerates further improvements and adds functions that contribute to safety and productivity.

– Autonomous transfer of parts for other mining equipment working in the field.

– Autonomous transfer of equipment operators for other machines such as loading equipment or bulldozers

Since Komatsu launched the world first commercial application of AHS in 2008, the company has deployed over 650 trucks at 22 sites in five countries (as of May 2023).

ALSO READ:

Swedish mining major to use Volvo electric trucks for heavy underground transport

Caterpillar develops giant battery electric mining truck

Allison Transmission and SANY eye demand for mining dump trucks in India

Hindustan Zinc deploys heavy-duty EV for underground mining operations