The automotive world continues to evolve around the four major pillars of ACES (Autonomous, Connected, Electrified, and Shared).At the heart of this revolution are Software Defined Vehicles (SDVs), which are reshaping traditional chassis designs into cutting-edge, software-driven frameworks. In this article, we explore how modern chassis architectures are evolving to meet the demands of SDVs, delivering unprecedented safety, connectivity, and driving dynamics.

Need for SDVs:

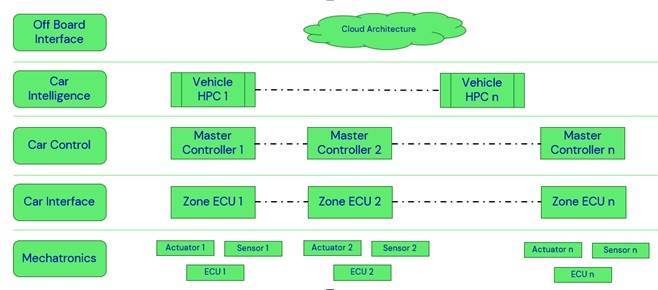

Traditionally, the three basic chassis functions—braking, suspension, and steering—were governed by respective actuators (hardware) and their associated software through ECUs. These smart ECUs, with their own code, flashed into memory and controlled the strategy. As more components become electrified, the number of ECUs in a vehicle has increased exponentially. Today’s connected cars are said to have 50 to 80 million lines of software code. The current strategy of using multiple ECUs is no longer sufficient in terms of power and capacity. This necessitates a high-performance computer to centrally manage all these functions, processing large volumes of data at high speed.

Moreover, vehicles with such extensive software integration require timely updates. This creates the need for architectures that can be updated “Over the Air,” enabling the FOTA/SOTA approach.

OEMs aim to seamlessly enhance and realize new features on vehicles, far beyond the embedded capacity of the hardware, by leveraging cloud capabilities. This allows customers to receive a “refreshed and updated” vehicle at regular intervals, enhancing their post-purchase experience. All these needs are met by a platform architecture known as the Software Defined Vehicle. SDVs are controlled by a central high-performance computer, governing all vehicle functions to deliver seamless, integrated performance. These SDVs are also FOTA/SOTA-enabled, meaning vehicle features can be updated via the cloud.

Evolution of Chassis Design

In the conventional approach, chassis designers started by selecting hardware based on the properties of the powertrain, suspension, and steering to achieve the desired vehicle dynamics. Each component had its own ECU integrated into the vehicle’s E&E architecture through a CAN bus, but each control unit transmitted signals to its respective actuator, making signal integration increasingly complex. To ensure a safer, more pleasurable driving experience, all components needed to be connected in a synchronized manner.

The SDV chassis, however, is developed differently. The first consideration is the driving characteristics the vehicle should have, after which hardware technology selections and E&E strategy are made to achieve these desired characteristics. A centrally located high-performance computer governs actuation strategies, enhancing driving dynamics, safety, range, and ride comfort.

When designing chassis components for software-driven vehicles, using the right materials—such as high-strength alloys or carbon fiber composites—ensures optimal performance at an efficient cost. This strategic material selection improves durability, reduces weight, and enhances overall vehicle dynamics, providing a balance of safety, efficiency, and affordability. The SDV chassis also supports V2X communication, warning other vehicles about traffic jams, unsafe road conditions, and bad weather, enhancing both safety and driving pleasure.

SDV Chassis – Skateboard approach

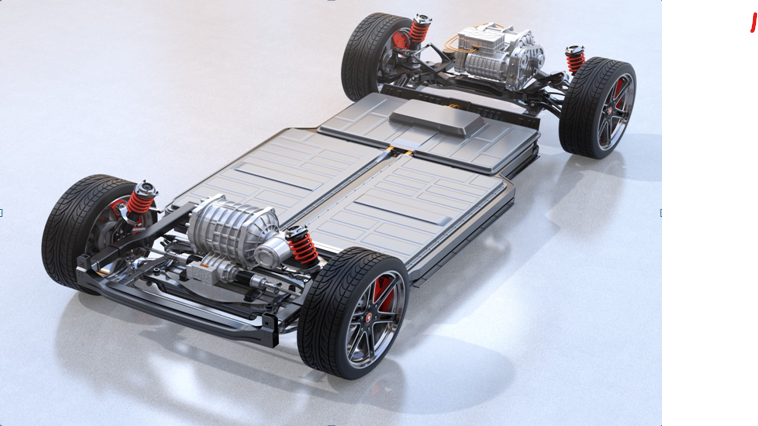

Let’s explore how these requirements translate into the design of a multipurpose skateboard chassis. Essentially, it integrates high-performance actuators like electronically controlled dampers, foundation brakes, electric power steering, suspension, battery, and EDU. A high-performance computer (HPC) is then overlaid to synchronize the performance of all these components. This is known as the skateboard platform. Such a platform can be used to create multiple variants of SDVs by adding different top hat designs, meeting OEMs’ requirements.

A typical EV Skateboard

The same skateboard platform can deliver the driving dynamics of a family sedan, a sporty SUV, or even a supercar with the push of a button! This platform also enables OEMs to offer subscription-based features. For example, the Mercedes EQS offers a standard rear-steer angle of 4.5 degrees, but with a subscription, it can be increased to 10 degrees, dramatically reducing the vehicle’s turning circle.

X by wire Systems- key enablers for SDV Chassis Architectures

For ADAS Level 2 and beyond, vehicle computers largely control longitudinal and lateral behaviour, requiring greater access to these systems. X-by-wire technology complements these software-controlled actuators perfectly. For instance, decoupling the steering wheel from the steering gear allows for infinite steering ratios, enabling agile, sporty steering on highways and light effort while parking.

Steer-by-wire systems also simplify vehicle packaging, as the same steering gear can be used for both left-hand drive (LHD) and right-hand drive (RHD) versions of the car, making tooling, assembly, and service more cost-

effective. Similarly, the central computer controls the braking system and EDU, achieving a precise mix of regenerative and friction braking. This optimizes brake wear and enhances energy recovery.

The shift from hardware-dependent systems to software-driven architectures marks a new era in automotive engineering. SDV chassis designs, powered by modular skateboard platforms and advanced by-wire technologies, are paving the way for safer, smarter, and more personalized driving experiences. As the automotive landscape continues to evolve, SDV chassis engineering will remain at the forefront, enabling the vehicles of tomorrow to redefine mobility as we know it.

Darshan Muley is Global Head, Chassis Centre of Excellence, Tata Technologies. Views expressed are his own.