Learn how ruggedized charging cable management supports effective fleet EV deployment.

The exploding growth in the popularity of electric vehicles brings the need for effective and safe charging infrastructure. The industry has already seen how the lack of charging infrastructure has restrained consumer EV acceptance, compounded by high failure rates of the existing infrastructure. For commercial truck fleet operators to make the switch to electrons instead of diesel fuel, Level 2 AC charging and Level 3 DC fast charging stations become crucial. The installation of commercial-scale EV charging infrastructure necessitates proper equipment installation and cable management.

This discussion will consider how ruggedized charging cable management for fleet deployment offers three key benefits supporting the long-term success of commercial EVs: enhanced safety for both personnel and equipment, maximized uptime, and overall ROI.

Why is now the time to plan infrastructure?

The current state of the fleet EV market makes this the right time to look at infrastructure issues. Almost all major truck makers are shipping or have announced electric vehicles as well as contracts with operators for future EV deliveries. The number of EVs already on our streets and highways are growing rapidly. Here are just two examples:

- Electric school buses from Thomas Built Buses use a battery electric drive system provided by Proterra. By early 2023, they had already driven over one million miles in school districts across North America.

- Electric delivery vans from EV manufacturer Rivian help online retailer Amazon bring packages to homes and businesses across the US. By the end of the first quarter of 2023, this fleet included 3,000 vans in more than 500 cities. Rivian is in the process of fulfilling the total order for 100,000 EVs to Amazon.

Considering Level 2 or Level 3

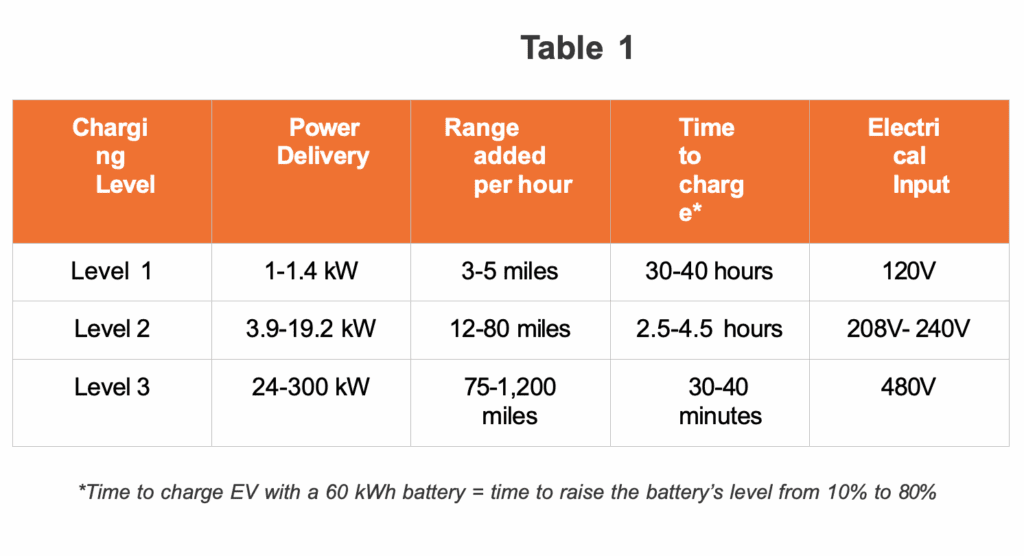

Construction of charging infrastructure for fleet purposes is determined by the type of charging systems required. Level 1 charging was normal for early consumer EVs and utilized 120V residential voltage systems. It has generally been superseded by Level 2 chargers, which require a 240V electric supply to charge vehicles more quickly. Level 3 chargers provide still faster charging, but with much more robust equipment requirements. See Table 1 for a general comparison.

Level 2 charging stations deliver electrical current from an outlet or hardwired unit to the vehicle via a connector like a standard-issue charger. They require a 208-240V power source with a dedicated circuit up to 80A. On average, this type of charger will add 32 miles of driving range per hour of charging.

Level 2 charging is well-suited for residential service or retail service for consumer passenger EVs. In fleet applications, this level of charging is good for vehicles that are used for a few hours and can recharge for a couple hours or used for a day shift and then charged overnight. For example, Level 2 charging is common with last-mile electric delivery trucks or vans.

Level 3 require a 480V electrical source, typically needing additional service from the utility company. These chargers can deliver a full charge in about 30 minutes, adding up to 20 miles of ranger per minute. Level 3 charging is better suited for long haul over-the-road semi-trucks or buses and delivery vehicles which cover a greater range during the shift while making frequent stops.

Cable management becomes critical

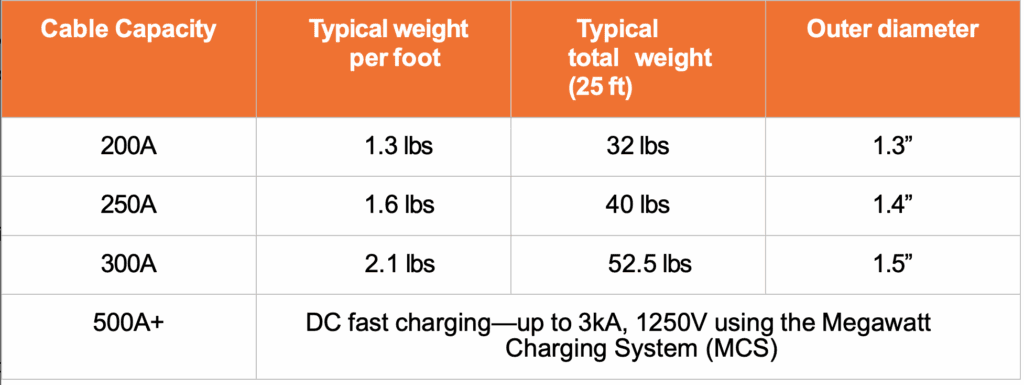

The voltage and amperage differences between Level 2 and Level 3 require different equipment. While the internal differences may not be visible to users, the cable certainly is. The physical difference in cables create differences in how each system functions.

Because of heat in the cable, many higher amp cables include built-in cooling. That also adds bulk and weight to the cable. See Table 2 for a typical comparison.

Table 2

Proper cable handling becomes important with Level 2 and even more so with Level 3 systems. The larger cable diameter can become a trip hazard for users. Since they are heavier, a cable left dangling can cause damage to the connector, the charger itself or the vehicle, or a person.

Level 3 cables are much thicker and heavier than those used with Level 2 charging stations. These cables require more support and protection to ensure they do not become damaged or pose a safety risk.

Cable management is the process of organizing and routing cables in a safe and functional manner. It becomes essential for Level 3 DC fast charging stations because of the high voltage and current levels involved.

Choosing the right build-out for the application

For today’s commercial fleet operators, the transition to EVs offers great opportunities. The specific make-up of the fleet, incorporating Level 2 or Level 3 charging or a mix of both, influences the type of equipment installation.

Cables for Level 2 chargers can often be managed with simple spring motor-powered reels. These are common with last-mile delivery vehicle fleets. Larger Level 3 cables require more robust, advanced management. Along with motorized reels, balancers help keep the heavy cable maneuverable and off the ground. As EV semis become common, this type of infrastructure will grow.

Alternate systems, such as the pantograph, are being promoted by some manufacturers for EV applications like public transportation buses. As a bus pulls into the booth, arms lower the charger contact pads down to meet contacts on the vehicle roof. Proponents suggest that this type of system is more convenient for vehicles that drive regular routes over long shifts, allowing them to charge on the fly. However, each system requires much higher initial investment and must be built to one specific vehicle type. The moving parts involved in pantograph systems also introduce another possible point of mechanical failure.

Concurrent to building out the infrastructure in the fleet yard, future consideration must be given to long-haul service centers—the truck stop market. In this application, charging equipment must be able to serve a variety of EV types, makes and models.

Answering safety questions

Safety for commercial EV charging cables involves several different aspects.

When not stored properly, the cables themselves become susceptible to damage from being dragged on the ground or being run over by vehicles. If part of an unmanaged cable rubs against or contacts a sharp object or edge during use, it can be accidentally scraped or even cut. Damage to cables increases operator costs.

At the same time, reducing the risks of trip hazards is equally important. Loose cables on the ground present dangers to drivers, other users, service personnel, and EV and facility owners. If cables are not managed properly, they can become tangled, which can increase the danger. OSHA recordable injuries from falls hurt productivity and raise costs. With Level 3 charging stations, the higher voltage levels involved also pose a greater risk of injury if a cable’s outer sheath becomes damaged.

Good management also helps protect cables from environmental factors such as UV exposure

and harsh weather conditions which can degrade performance. Properly managed cables last longer, reducing maintenance costs over time.

Maximizing equipment and vehicle uptime

Proper cable management extends the life of the cable and helps maximize uptime for the charging equipment. Damage to cables can be costly—not only the replacement cost of the cables themselves but long lead times for replacement cables will leave your charging station non-functional during the wait.

Maintaining charging equipment uptime keeps vehicles running. For commercial EV fleet operators, cable management supports a healthy return on investment.

Cable management best practices

The reel industry has a long history of protecting investment through providing proper cable management. Gleason Reel has the advantage of over 100+ years’ experience supporting heavy industries, such as mining, steel mills, and transportation. The lessons learned in these markets can be applied for success in the commercial and industrial EV space.

Several best practices are key to ensuring proper cable management for Level 2 and Level 3 charging:

- Mounting System: Is the EV charging cable mounted on the ground (on a pylon) or on a wall? Is it mounted overhead? Different mounting orientations (ceiling, ground, or surface) require different solutions for retracting or supporting the cable. The heavier the cable, the more likely a set of balancers will be needed to keep the cable off the ground.

- CableClamp: A cable clamp should be installed to support the cable itself. The clamp should be designed to handle the cable’s weight and it should be installed in a way that does not exceed the cable’s bend radius. Ideally, the cable clamp should be nonmetallic. That safeguards against any transfer of current if the cable is damaged and the conductors touch the cable clamp.

- CableProtection: Devices such as covers and guards prevent damage to the cable from environmental factors such as harsh weather conditions and UV exposure. They also protect cables from being accidentally cut or damaged during use. If part of a cable rubs against or contacts a sharp object or edge, additional protection (such as Burndy heat shrink polyolefin sheathing or a Kellems wire mesh grip) may be needed.

- Cable Labeling/Identification: In settings with multiple charging stations, each cable should be labeled to indicate its function and voltage rating. This helps to prevent confusion and ensures that the correct cables are used for each charging session.

History and the current industry situation demonstrate why proper cable management is important to support the growth of the commercial EV market. Not only for Level 2 charging, but it becomes a necessity for Level 3 DC fast charging.

Ruggedized EV charging architecture that follows cable management best practices provides key benefits for fleet EV operators. Maximizing charging station uptime and protecting cable life to maximize the return-on-investment helps create a lower total cost of ownership. They also ensure a safe and reliable charging experience for users and service personnel.

Gleason Reel offers a variety of EV charging cable reels to handle any application.

To learn more, watch the recent webinar, “Exploring cable management strategies for DC fast-charging EV fleets,” and contact Hubbell today:

gleasonorders@hubbell.com

(920) 387-4120

www.hubbell.com/gleasonreel