Ultramid® setzt neue Maßstäbe für die Brennstoffzelle / Ultramid® is setting new standards for fuel cells

LUDWIGSHAFEN, 11-Mar-2019 — /EuropaWire/ — BASF, as the biggest chemical supplier to the automotive industry, is very active on and engaged with things like automotive drive system, energy consumption, emissions, new and improved powertrain concepts for cars, electric drive concepts, among others, along with the major car manufacturers. In general, chemistry is making an important contribution to a number of different electric drive concepts.

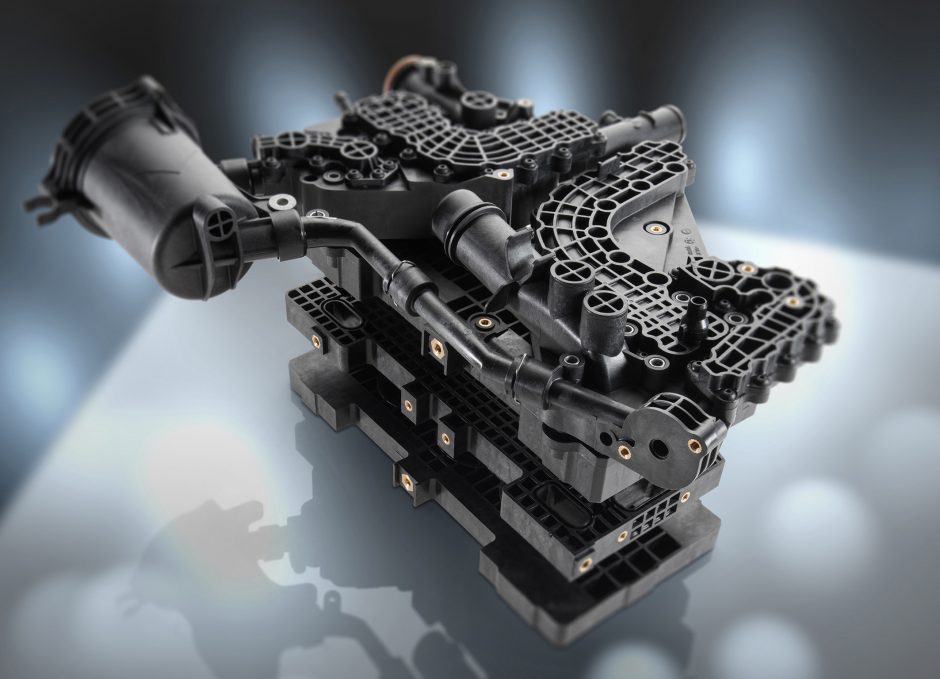

And now a breakthrough is made in the field of fuel cells. BASF’s Performance Materials is working closely with Joma-Polytec and Daimler AG’s subsidiary Mercedes-Benz Fuel Cell over the engineering plastic Ultramid, which has successfully been used to manufacture a number of fuel cell system components. The Ultramid is already in use as standard in the new Mercedes GLC F-CELL, which combines a fuel cell with a rechargeable lithium-ion battery.

Andreas Stockheim, Segment Manager Powertrain and Chassis at BASF:

“Our extensive plastics portfolio offers all sorts of advantages which help us to satisfy specific customer requirements, depending on the drive concept and the specific component. By continually developing new products in close collaboration with our customers, we are also able to adapt our portfolio to trends and changes in the market.”

Plastics are seen to be increasing efficiency across all of the different engines, from hybrid, plug-in and electric vehicles to internal combustion ones.

The automotive industry places huge demands on materials with its stringent requirements on high quality and safety. BASF is able to keep pace with the latest developments of car manufacturers, while also setting innovative trends with its polyamides (Ultramid), polybutylene terephthalates (Ultradur®), polyphthalamides (PPA), and the plastics polyoxymethylene (Ultraform®) and polyethersulfone (Ultrason®)

For example, the Mercedes GLC F-Cell is hugely reliant on Ultramid’s properties such as good thermal and chemical resistance, dynamic stiffness, impact strength, and good long-term performance.

Stefan Milimonka, Key Account Manager in BASF’s Performance Materials division:

“Earlier tests with other materials revealed mechanical problems, so Daimler had very specific requirements for the material. Our expertise with plastic automotive components and the extensive choice of existing products meant that we were able to work out possible solutions with our partners and identify the right material. It shows that with specialist knowledge and good cooperation between everyone involved, a complex project like this can be brought to a successful conclusion.”

New development project has been established together with Joma-Polytec GmbH and Mercedes-Benz Fuel Cell GmbH in order to find an optimal solution satisfying the extensive range of requirements including thermal stability, media resistance, and durability.

Based on an intensive material analyses of the chemical and mechanical resistance, a decision has been made on the tailor-made Ultramid grades A3WG10 CR and A3EG7 EQ.

Following rigorous testing of all components, the two glass fiber-reinforced Ultramid grades are now in use as standard to manufacture the anode- and cathode-end plate in fuel cells.

The exceptional purity requirements associated with sensitive applications in the electronics industry has made the Ultramid A3EG7 EQ as an ideal material. Ultramid A3EG7 EQ offers excellent resistance, while meeting all requirements regarding the purity of the material in the case of the media distribution plate and the water separator unit, which is exposed to a wide variety of media through the cooling water, air and hydrogen channel.

Stefan Heinz, deputy head of plastics technology development at Joma-Polytec GmbH:

“Thanks to BASF’s extensive product portfolio and the specialist knowledge of all the parties involved, we have taken an important step forward in the serial development of fuel cells. We worked together to analyze the stringent requirements and were able to put in place a highly efficient solution.”

BASF’s Performance Materials is active in four major industry sectors – transportation, construction, industrial applications and consumer goods encompassing the entire materials know-how of BASF regarding innovative, customized plastics under one roof.

For nearly 60 years, Joma-Polytec has been developing comprehensive solutions in the field of plastic technology for its customers from the prototype, through the production to the subsequent support.

Mercedes-Benz Fuel Cell GmbH is part of the global fuel cell activities of Daimler AG. The company is active in the research and development of fuel cell systems for motor vehicles, including hydrogen tank systems, in addition to laying the groundwork for hydrogen infrastructure and carrying out demonstration projects.

The company is stepping on profound and long-established expertise in fuel cell technology. Since 1997 activities for the development of fuel cell systems are based at the Nabern location near Kirchheim-Teck. The original initiator was Ballard Research Inc., which founded in 1979 by Geoffrey Ballard in Burnaby, Canada. In 1983 fuel cell technology was developed at Ballard for the first time. 1993 saw the presentation of the first bus to be powered by hydrogen-technology fuel cells. The first ever product of this type was made available on the market in 2001.

Media enquiries can be directed to Max Kron at +49 621 60-42223 and max.kron@basf.com.

SOURCE: BASF SE

MORE ON BASF, PLASTICS, FUEL CELLS:

- Lufthansa starts the In-Service-Evaluation (ISE) for BASF’s new water scavenger additive for jet fuel – Kerojet® Aquarius – BASF and Lufthansa have successfully started the In-Service-Evaluation (ISE) for BASF’s new water scavenger additive for jet fuel – Kerojet® Aquarius….

- Aalborg University: plastic grid can increase the efficiency of an air-cooled fuel cell stack by over 30 percent – A plastic grid that costs less than a dollar to produce can increase the efficiency of an air-cooled fuel cell stack by over 30 percent, as demonstrated by research from Aalborg University…

- FaHyence Project Gets Commission for First Hydrogen Refueling Station in France – On 11 April 2017, the hydrogen refueling station of the FaHyence project was officially commissioned in the presence of Mr. Roland Roth, President of the Communauté d’agglomération Sarreguemines Confluences (CASC) and Didier Vaucois,…

- GasTerra finances the fuel cell car of TU Delft’s Car as Power Plant project – In the future, hydrogen fuel cell cars will also be able to provide energy for houses and offices. These cars run on electricity which is produced from a hydrogen fuel cell….

- Aerospace and data analytics company Planet and BASF to deliver timely satellite imagery and data to European farmers – Analytics from daily satellite imagery will promote better land and agricultural practices BASF’s xarvioTM digital products and Planet will contribute significantly to more sustainable agriculture in Europe…

- BASF developed an online solution-finder for construction projects in the food-and-beverage, chemical, and wastewater-engineering industries – Find the right solution – anytime, anywhere and across all end devices View and understand details through clear explanations Request advice and a consultation easily…

- Alliance of key industry stakeholders covering the full plastics value chain established to reduce plastics littering across Europe – Today (11 December 2018), the European Commission launches an alliance of key industry stakeholders covering the full plastics value chain as part of its persisting efforts to reduce plastics littering, increase the share of recycled…

- Nestlé signs The New Plastics Economy Global Commitment – Nestlé today joined forces with other businesses and governments in signing The New Plastics Economy Global Commitment (‘Global Commitment’) at the Our Ocean Conference in Bali, Indonesia. The Global Commitment is an initiative of The Ellen MacArthur…

EDITOR'S PICK:

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 4 and 8 March 2019

- Digi Communications N.V. announces share transaction made by an executive director of the Company with class B shares on 4 march 2019

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 25 February – 1 March 2019

- Digi Communications N.V. announces share transaction made by an executive director of the Company with class B shares on 1 march 2019

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 18 and 22 February 2019

- Digi Communications N.V.: finalization and registration by the Company of the conversion of 1,200,000 A shares into an equal number of class B shares

- Digi Communications N.V.: Exercise of stock options by a PDMR in accordance with the stock option plan for the Group’s Romanian employees

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 11 and 15 February 2019

- Report of legal documents concluded by DIGI Communications N.V. in January 2019 or in other period but effective in January 2019

- Digi Communications N.V. announces Availability of Preliminary Financial Report for the year ended December 31, 2018 for Digi Communications N.V. Group

- Mono Solutions launches a new interface to drive the ultimate do-it-with-me (DIWM) experience

- Digi Communications NV Announces Investor Call on the Preliminary Financial Results for the year ended 31 December 2018

- Digi Communications NV: New date of the Conference Call for the 2018 Preliminary financial results; Update to the 2019 Company’s Financial Calendar

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 4 and 8 February 2019

- R.W. Chelsea Holdings Ltd Starts To Hold Fixed Income Investor Meetings In Vienna, Zurich, Geneva and London

- Digi Communications N.V. successfully increased and priced its Offering at €200,000,000 5.0% additional senior secured notes due 2023

- Digi Communications N.V. to offer additional €125,000,000 5.0% senior secured notes due 2023; new notes will be consolidated and treated as its existing €350,000,000; adjustment on interim unaudited consolidated financial statements for the nine-month period ending September 30, 2018

- World's largest superhero statue to be built in Central Europe

- The resignation of Mr. Bendei Ioan – VP and executive director of RCS&RDS S.A., DIGI COMMUNICATIONS N.V.’s subsidiary in Romania

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 28 January 2019 – 1 February 2019

- RCH Group to Showcase Integrated Selling Solutions at EuroCIS

- Mono and bfound partner to expand digital offerings for small businesses in the Middle East

- Digi Communications N.V. publishes the Independent Limited Assurance Report in accordance with Law 24/2017 (Article 82) and FSA Regulation no. 5/2018

- ERRATA of the reports dated 15 Jan 2019 and 15 Oct 2018 regarding the legal acts concluded by DIGI Communications N.V. in Dec 2018 and Sep 2018

- REVEALED: Experts reveal the best dates to book your summer holiday in Spain

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 21 – 25 January 2019

- Céline Dion visite son premier concept store de vêtements CELINUNUNU à Paris

- Anytime, anywhere tailored learning opportunities for welding professionals and apprentices alike

- i5invest открива офис в България

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 14 – 18 January 2019

- Mono helps Fonecta strengthen their digital presence offering for SMBs

- The Bucharest Tribunal’s decision regarding the investigation conducted by the Romanian National Anti-corruption Directorate with respect to RCS & RDS S.A., Integrasoft S.R.L. and certain of their directors

- Digi Communications N.V.: Exercise of stock options by a PDMR in accordance with the stock option plan approved by the Company for the Romanian employees of the Group in 2017

- Report of legal acts concluded by DIGI Communications N.V. in accordance with Romanian Law no. 24/2017 and FSA Regulation no. 5/2018 for December 2018

- Digi Communications N.V.: resolution of the Board of Directors to convert class 1,200,000 A shares into an equal number of class B shares for the purpose of the ongoing employees and directors stock option plans

- CELINUNUNU OUVRE SON PREMIER POP-UP À PARIS

- DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 07 – 11 January 2019

- Digi Communications NV: Announcement of the Conference Call for the 2018 Preliminary financial results. Update to the 2019 Company’s Financial Calendar

- A new Government Emergency Ordinance imposing additional corporate taxes with impact on the telecommunications sector in Romania

- DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 31 December 2018-04 January 2019

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 24-28 Dec 2018

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 17-21 Dec 2018

- US Customer Data Platform authority David Raab to Host First CDP Workshop in Belgium

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 10-14 Dec 2018

- US-amerikanischer Customer-Data-Platform-Experte David M. Raab leitet ersten gemeinsamen CDP-Workshop mit b.telligent in München

- Arriva Designflows, la prima competizione di mobile design in Italia

- BWW 2018 – Best Wine Critics of World have been selected – Jancis Robinson MW is the Winner!

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 3-7 December 2018

- Farming by Satellite Prize is won by Teagasc from Ireland

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 26-30 Nov 2018

- Notification shares buy-back: Digi Communications N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 19-23 November 2018

- First Non-Melanocytic Skin Cancer Patients treated with Rhenium-SCT® in South Africa

- Notification shares buy-back: Digi Communications N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 12-16 November 2018

- Base Element and Cognigy Announce Strategic Partnership

- Digi Communications N.V. announces the Hungarian Competition Council’s decision to formally withdraw and reassess the Invitel merger decision on certain limited aspects

- Amerikaanse Customer Data Platform authoriteit David M. Raab leidt eerste CDP Workshop in Nederland

- Digi Communications NV announces the release of the Q3 2018 Financial Results

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 5-9 November 2018

- Cobots and RPA Gain Centerstage in Automotive Robotics Space; Labor Issues Prevail as a Key Challenge

- Digi Communications NV announces Investor Call on the Financial Results for Q3 2018

- Food Waste Recycling Machine Sales to Reach 10,890 units in 2018 on the Back of Growing Investments in Sustainable Solutions

- SMEs Accounted for Nearly 60% Share of SAP Cloud Platform Services Market in 2017, Finds New Fact.MR Study

- China’s Dominance of Pneumatic Rollers Production and Demand Continues, Finds Fact.MR Study

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 29 October-2 November 2018

- ILC Dover to Open New Production Facility in Blarney, Ireland for Added Capabilities, Capacity and Jobs

- OEMs Hold 90% Share of Automotive Switches Sales Channel, Finds Fact.MR

- US$ 3 Billion RF Power Amplifiers Market Driven by Growing Cellular Applications, Finds Fact.MR Study

- Kidney Stone Management Device Sales to Surpass 340,000 Units in 2018 with Lithotripsy Devices Leading the Rally, Finds Fact.MR

- Fact.MR Study Finds Contractor Preference Shifting from Skid Steers to Compact Track Loaders in Lucrative Markets

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 22-26 October 2018

- DB CyberTech Launches into the European Market

- Hungarian coding bootcamp opens in Prague in order to train career changers looking to enter the IT industry

- Gasoline Vehicles Accounted for 8 in 10 Automotive Fuel Injector Sales in 2018, finds Fact.MR Study

- Fact.MR Study Finds Global Demand for Crawler Cranes to Reach 3,648 Units in 2018, Greater China Leads with 30% Share

- Surplus Supply Reflects Growing Avidity in the Europe Cocoa Market – Fact.MR Study

- Fact.MR Study Shows Declining Demand for Tilapia in US Offset by Encouraging Gains in Domestic Markets

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 15-19 October 2018

- Europe Home Diagnostics Market Driven by Burgeoning Glucose Monitoring Device Sales, Consumer Demand for Non-Invasive Kits Largely Unmet – Fact.MR Study

- Europe Bicycle Parking Racks Market Driven by Consumer Focus on Sustainability and Carbon Consciousness

- Halloumi Cheese Popularity Soars in Europe as UK Maintains its Lead as the Largest Market – Fact.MR Study

- Vehicle Interior Air Quality (VIAQ) Takes Centerstage in US$ 6.5 Million Europe Automotive Headliners Market

- Report of legal acts concluded by DIGI Communications N.V. in accordance with Romanian Law no. 24/2017 and FSA Regulation no. 5/2018 for September 2018

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 8-12 Oct 2018

- Europe Emulsifier and Co-Emulsifier Market Witnessing a Shift Towards Bio-based Variants – Fact.MR Study

- Fact.MR Study on IBM Watson Services Market Lists Business Agility and Customer Service Transformation as Key Motivations to Adoption

- Europe Non-Dairy Toppings Market Riding on the Coattails of Growing Vegan Revolution, Finds a New Fact.MR Study

- Blockchain Cyber-security Firm Privus Raises $635k in Late Stage Seed Funding

- ‘Sustainability’, ‘Functionality’ and ‘Cost-Effectiveness’ Among Key Expectations of European Consumers from Automotive Tow Bars Industry

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 1-5 Oct 2018

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 24-28 Sept 2018

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 17-21 Sept 2018

- New Study Reconfirms Effectiveness and Safety of Fotona Dynamis Laser Treatment for Minimally-Invasive Urinary Incontinence

- New study reveals that hate speech is becoming the ‘new normal’ on social media

- The launch of fixed broadband and fixed telephony services by Digi Communication N.V.’s subsidiary in Spain

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 10-14 Sept 2018

- coMakeIT appoints Durga Prakash Kone as Head of Global Sales

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 3-7 Sept 2018

- 80% Satisfaction Rate in Europe for Customer Data Platform Early Adopters

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 27-31 Aug 2018

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 20-24 Aug 2018

- DB CyberTech Launches GDPR Continuous Monitoring Solution with the First to Market Advanced Data Classification

- DATA4 Brings Pioneering Payment Systems to Kiosk Summit 2018

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 13-17 Aug 2018

- Digi Communications NV announces the release of the Q2 2018 Financial Results

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 6-10 August 2018

- Plus Ultra strongly denies the fraud allegations bought against them in the Spanish class action lawsuit

- Digi Communications NV announces Investor Call on the Financial Results for H1 2018

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 30 July-3 August 2018

- Europe’s largest battery and H/EV event moves to manufacturing hub for e-mobility

- Mono Solutions announce a new partnership with PA DIGITAL, the leading provider of digital services for small businesses in Spain

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 23-27 July 2018

- Digi Communications N.V. publishes report of legal acts concluded by the company in accordance with Romanian Law, FSA Regulation as well as the Independent Limited Assurance Report

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 16-20 July 2018

- RCH Europe Brings New Innovative Selling Solutions to FAFGA 2018

- Lanzamiento de un nuevo sitio web de comparación financiera

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 9-13 July 2018

- European Customer Data Platform Vendors Lead Industry in New Direction

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol, 2-6 July 2018

- iBwave Design Helps MTS Deliver Superior Fan Experience During the 2018 Soccer Games in Russia

- Get Ahead Of Your Business Competition with Customized Advertising Campaigns by Manesta Programmatic Agency

- Digi Communications N.V. announces the publishing of ANCOM approval for RCS & RDS S.A. to continue to apply a surcharge for certain roaming services provided in the EEA for a renewed period of 12 months

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 25-29 June 2018

- Euro Staff Solution: First 2 Employees are on Us

- Press conference: Illegal sales of Schengen and Medical Visa Scandal involving Maltese PM’s Office

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol between 18-22 June 2018

- Notification shares buy-back: DIGI COMMUNICATIONS N.V. reports to the regulated market the transactions which occurred under the DIGI symbol (June 11-15, 2018)

- Settlement of litigations between RCS & RDS S.A. and Antena Group entities

- Dr. Christina Marrongelli to lead World Congress on Pharmacology & Chemistry of Natural Compounds

- Report of legal acts concluded by DIGI Communications N.V. in accordance with Romanian Law no. 24/2017 and Rule no. 1/2006 of CNVM – May 2018

- 40 miljoen liter verdwijnt onnodig in het europese millieu | Stem op Cleanprotec | Dave Bebelaar award 2018

- Mit der Eröffnung eines neuen Büros in Spanien stärkt IN-GRY seine Präsenz in Europa

- Con la inauguración de una nueva sede en España, INRGY reforzará su presencia en Europa

- With the opening of a new office in Spain, IN-RGY strengthens its business presence in Europe

- Avec l’ouverture d’un nouveau bureau en Espagne, IN-RGY renforce sa présence commerciale en Europe

- Revealed: Top Tips for Sunseekers on a Shoestring in Spain

- Qoobo, a Pillow That Wags Its Tail to Your Touch, Is Coming to CEBIT

- Digi Communications NV: The initiation by the Company of the share buy-back program as authorized by the Company’s GSM from 2 May 2018

- NIKITA ONLINE veröffentlicht ein neues Spiel: «Panic Room 2: Versteckspiel»!

- NIKITA ONLINE lance un nouveau jeu «Panic Room 2: Jeu de cache-cache»!

- NIKITA ONLINE launches a new game, «Panic Room 2: Hide and Seek»!

- Nagarro sets up technical center in Malta to focus on growing iGaming clientele

- Digi Communications NV: The closing of the acquisition by the Company’s Hungarian subsidiary, DIGI Távközlési és Szolgáltató Kft., of the Hungarian telecommunications operator Invitel Távközlési Zrt.

- Digi Communications NV Stock option plan meant for the employees and officers of Digi Spain S.L.U. and conditional stock options granted to certain Romanian directors and employees

- Leading European Crowdfunding Firm FundedByMe Kicks-Off Property Portal MIPARO’s Campaign May 21

- Digi Communications NV Announces that Conditional stock options were granted to several Directors of the Company based on the general shareholders’ meeting approval from 2 May 2018

- Digi Communications NV Announces the Exercise of stock options in accordance with the stock option plan approved at the level of the Company in 2017 for its Executive Directors

- Vor Beyoncés Blockbuster-Tournee durch Deutschland im Juli 2018 erscheint die lang erwartete Beyoncé und Destiny’s Child Dokumentation, die bei Amazon Direct in Deutschland erhältlich is

- Launch of new research journals European Journal of Sciences (EJS)® & European Journal of Social Sciences (EJSS)®

- Silver is Gold: The first European Silver Economy Awards have announced its winners

- Icelandair en het nationaal voetbalelftal creëren samen de Team Iceland Stopover: een reeks van 90 minuten durende, op voetbal geïnspireerde ervaringen

- Icelandair en collaboration avec l’équipe nationale de football créent la Team Iceland Stopover – une série d’expériences de 90 minutes inspirées du football

- Icelandair und die Fußballnationalmannschaft gestalten gemeinsam Team Iceland Stopover – eine Reihe von 90-minütigen, vom Fußball inspirierten Erlebnissen

- Icelandair and national football team co-create Team Iceland Stopover – a series of 90-minute football-inspired experiences

- Anti-rating: No leap of faith here: 15 countries with restrictions on cryptocurrency transactions

- ZOOM International Introduces GDPR Compliance in 6.3 Release

- Finer.es comienza su actividad

- Animal rescue hero loses his heroic battle with cancer

- International Association of Trampoline Parks (IATP) Jumping to New Heights in Europe – 2nd Annual EU Conference & Trade Show

- CONDA ICO: Whitelisting phase started as of April 1st

- International Day of Riding Announced

- April 10th, Conference in the European Parliament, Brussels, themed: A FUTURE FOR DEMOCRACY IN SYRIA

- Mono Solutions and Orange partner to expand digital services for SMBs in France

- Alliance Life Sciences is a Sponsor at World Pharma Pricing and Market Access Congress 2018, Showcasing Data and Technology Solutions

- Harald Xperience first in Finland to take augmented reality (AR) to restaurants

- 2018 ‘Farming by Satellite’ Prize seeks entries from across Europe

- BookingPal étend ses activités en France à mesure que les opérations européennes grandissent

- Schuster Manfred Hubert agrees with future oil predictions

- World Life Experience is headed to Ljubljana

- Whirlpools World Spain eröffnet in Teulada größten Whirlpool-Showroom in ganz Spanien

- Whirlpools World Spain opens biggest whirlpool bath showroom in the whole country

- RCH Group to Showcase Innovative Selling Solutions at EuroCIS

- MeetingPackage.com Präsentiert einzigartiges Reservierungsportal für Meetings & Events

- MeetingPackage.com Lance son Moteur de Réservation Exclusif pour Réunions & Événements

- MeetingPackage.com Introduces Unique Booking Engine for Meetings & Events

- ANECON becomes Nagarro

- UK Education Consultancy Services Ltd announced that the premiere issue of Scientific European® (a popular science magazine) is released on 19 January 2018

- RCH Europe to Present Smart Solutions for POS at INTERGASTRA 2018

- Raport: Jak zaoszczędzić na hiszpańskich wakacjach nad morzem

- Onthuld: zo vind je de beste deals voor je zomervakantie naar Spanje

- Finden Sie diesen Sommer die besten Spanien Angebote in der Zwischensaison

- Revealed: How to get the best value savings on your Spanish summer holiday

- Point of Sale Systems: RCH Group Expands European Operations

- Adomik a obtenu la 14e place au classement 2017 TECHNOLOGY FAST 500 pour la zone EMEA et la 3e place au classement Deloitte 2017 TECHNOLOGY FAST 50 pour la France

- Adomik auf Rang 14 der 2017 TECHNOLOGY FAST 500 EMEA und auf Platz 3 der Deloitte 2017 TECHNOLOGY FAST 50 für Frankreich

- Adomik Awarded #14 Ranking in 2017 TECHNOLOGY FAST 500, EMEA; #3 ranking in Deloitte 2017 TECHNOLOGY FAST 50 for France

- MeetingPackage.com Launches its Exclusive Affiliate Partner Program

- P2P Investment Loan Platform Enters Blockchain Sector with ICO Launch

- International Symposium on the Accessibility to High-Value Medicine, December 5-6, 2017, London

- Axiomatics Releases New Version of SmartGuard™ for Big Data

- No Time To Waste! Conference Takes a Practical Approach to Tackling Waste Crime

- HET DIGITALE EINDEJAARSVUURWERK VAN ONELIFE!

- LE FEU D’ARTIFICE DIGITAL DE FIN D’ANNEE DE ONELIFE !

- ONELIFE’S YEAR-END DIGITAL FIREWORKS!

- Alliance News riceve un investimento strategico da parte di PA Group e dpa per sostenere l’espansione nell’area EMEA

- #SUCCESVOL #VERHUIZEN: VERHUIZEN NAAR HET BUITENLAND

- #REUSSIR SON #EXPATRIATION: LE PARCOURS DE L’EXPATRIATION

- #SUCCESS IN #RELOCATION: THE RELOCATION JOURNEY

- 99X Technology hosts its first international breakfast seminar on digitalization in Oslo

- Spain-Holiday.com City Break Cost Index Autumn Winter 2017

- Continuing Growth Triggers Expansion and New Office in Spain for MeetingPackage.com

- 99X Technology drives digital disruption at Webdagene 2017 Oslo

- В Киеве состоится SphereCon 2017 – конференция, объединяющая Ruby on Rails, Go, разработчиков программного обеспечения и дизайнеров

- TechTrans Announces Partnership with Tidel (external link)

- Axiomatics Data-Centric Dynamic Authorization Product Suite Recommended in New KuppingerCole Analyst Report

- Throne of Lies, the highly anticipated online game of Deceit, launches on Steam

- SecBI and Innovery Announce Partnership to Promote SecBI’s “Autonomous Investigation” Cybersecurity Solution to the Italian and Spanish Markets

- "Heillandi Peking" Ljósmyndasýning um ferðalög haldin í Reykjavík

- Grammy Winner Coolio & Wrestling Legend Virgil on an Adult Star’s Presidential Ticket – Press Conference

- Invacare introduce their first touch screen remote

- Invacare International take powerchairs to a new level

- Industrial Laser Peening Research at ZAL Techcenter

- Blind Children Find New Hope Through Music in Wuhan, China

- Editor's pick archive….

-

Tweet

-

Share

0 -

Reddit

-

Pinterest

0

-

LinkedIn

0

-

Email