As cars are becoming connected, electrified and intelligent globally, Nissan is investing a sizeable 33 billion Japanese yen (Rs 2,145 crore) in production technologies for future automobiles. In sync with Nissan’s Intelligent Mobility vision, the investment is expected to help deliver a new generation of electrified and intelligent automobiles that also make production operations more flexible, efficient and sustainable.

Following an initial investment of roughly 33 billion yen at Nissan’s Tochigi Plant in Japan, the technologies will be rolled out across factories globally after work on them gets completed by 2020. This latest investment, as per Nissan, represents a necessary rethinking of conventional car making and tackles the structural and technical challenges of producing vehicles that will lead the industry in a new era of electrification and intelligence.

Hideyuki Sakamoto, executive VP for manufacturing and supply chain management, Nissan says, “We’re facing an unprecedented evolution in the capabilities of our vehicles. Our job is to make this evolution a reality by rethinking how we build cars. This will also mean shifting the efforts of our expert technicians from techniques they’ve already mastered to new, unexplored areas.”

New production technology

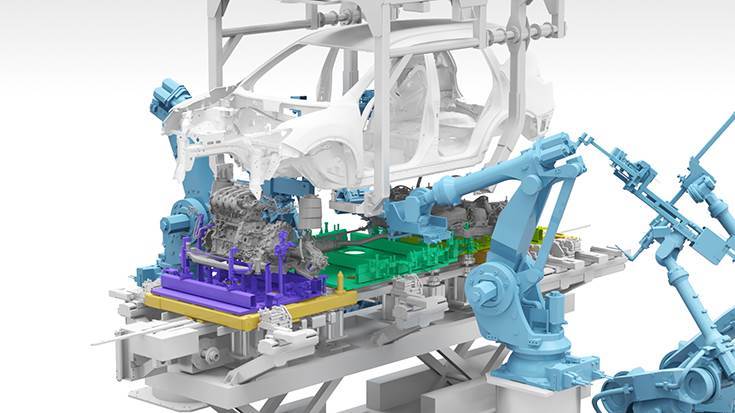

As companies get on with the business of creating more connected, intelligent and electrified units, it is also about adding layers of complexity to the design and the production techniques used to make it a reality. Nissan says it has identified the ‘universal powertrain mounting system’ as one such focus area. Mounting powertrains in cars makes for lengthy and strenuous work for assembly line staff, who have to install multiple components in sequence.

But this new Nissan system will use an automated pallet to mount the entire powertrain at once. The system measures the dimensions of the car in real time with the pallet makes micro-adjustments as per that. This ensures that powertrains are installed within a small fraction of a millimetre’s accuracy. The new system is adaptable and can mount 27 different powertrain module combinations. This same pallet can be used to mount pure electric, e-power as well as conventional internal combustion engines.

Enabling seamless construction

Nissan is also using this investment corpus to develop robots with specialist skills and processes that, until now, could only be performed by trained craftspeople. Nissan’s craftspeople and engineers have digitised parts of these delicate processes and ‘trained’ robots to perform them around the clock. This will allow the craftspeople to focus on new, unexplored areas of expertise.

One example of a task that can now be automated is sealing – applying a paste like material to seams around the vehicle body to prevent water intrusion. Sealing is generally done by experts, as the necessary dexterity and speed can be acquired through training but isn’t easy to replicate. But Nissan says it did not stop at just automating the process; its engineers analysed the precise movements and gestures of trained workers when smoothing and finishing sealant and calculated the pressure applied at each stage. They then converted this information to instructions for robots and made further adjustments through constant trial and error. As a result, robots can now apply and finish sealant precisely along even the most complex seams.

Ensuring consistent quality and improving workplace condition

As a result of the extensive trials, Nissan robots can now perform strenuous tasks efficiently, freeing workers to perform more valuable jobs elsewhere on the line. This also makes factories easier places to work. One example is the installation of a headliner, the overhead layer of material on the inside of a car’s roof.

Workers, thus far, had to manually enter each vehicle’s cabin to perform this physically demanding job. The connected features of the cars makes this task even more complicated. With robots working to insert the headliner through the front of the vehicle, not only has the process fastened up but the manual labour involved has also reduced. Sensors monitor changes in pressure and use a proprietary logic system to determine when the clips have snapped securely into place.

Betting on intelligent mobility

Nissan is also working to reduce the environmental impact of building cars. Changes in the painting process are especially noticeable. As Hideyuki Sakamoto, executive VP for manufacturing and supply chain management, says, “These new technologies and innovations are at the heart of the company’s competitiveness. They will be rolled out globally in the coming years.”

/news-international/nissan-to-pump-33-billion-yen-in-ultraefficient-production-methodologies-44786 Nissan to pump 33 billion yen in ultra-efficient production methodologies Nissan to pump 33 billion yen in ultra-efficient production methodologies https://www.autocarpro.in/Utils/ImageResizer.ashx?n=https://www.autocarpro.in/userfiles/0d5f6299-a1c7-40a8-a7c7-a79060ed5aea.jpg